Double-density double-color insole shoe production mold and using method thereof

A dual-density, bottom mold technology, applied in applications, household components, household appliances, etc., can solve the problem of inability to achieve effects, inability to achieve multi-layer color midsole, multi-layer midsole with different layer densities, inability to make multi-layer Different colors of midsole soles, etc., to achieve the effect of comfortable wearing and convenient modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

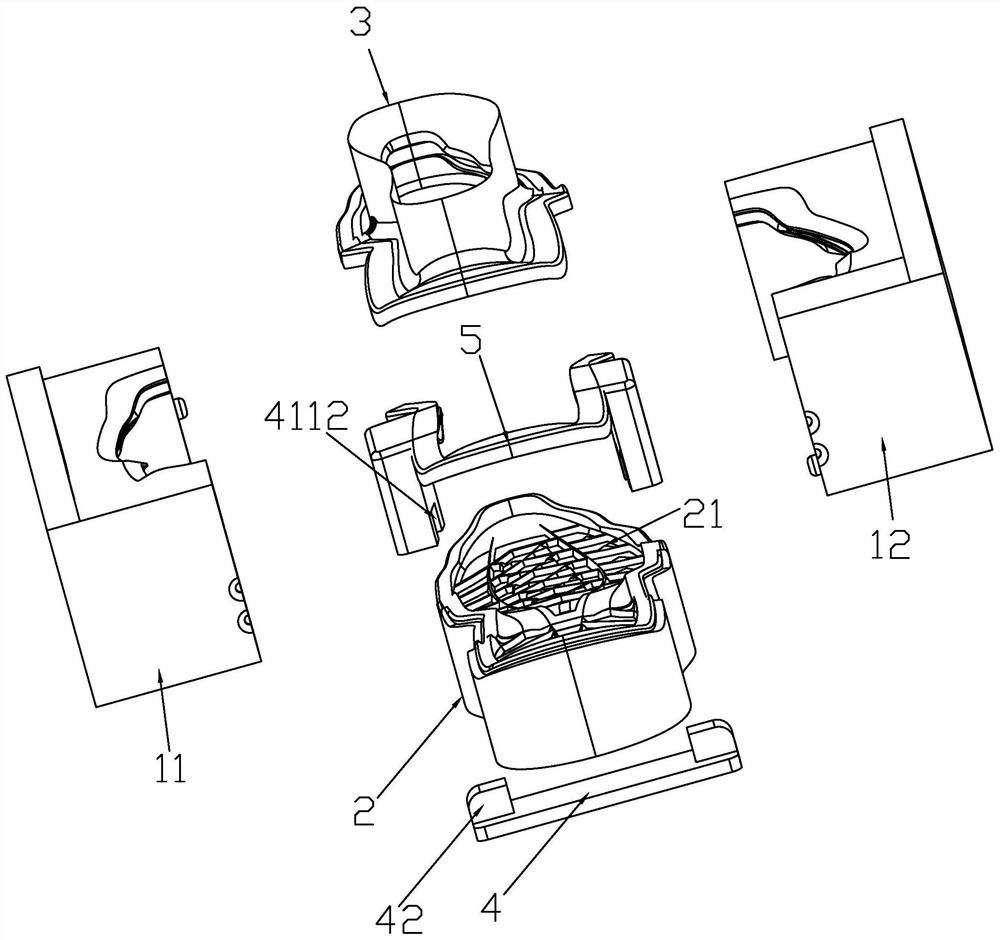

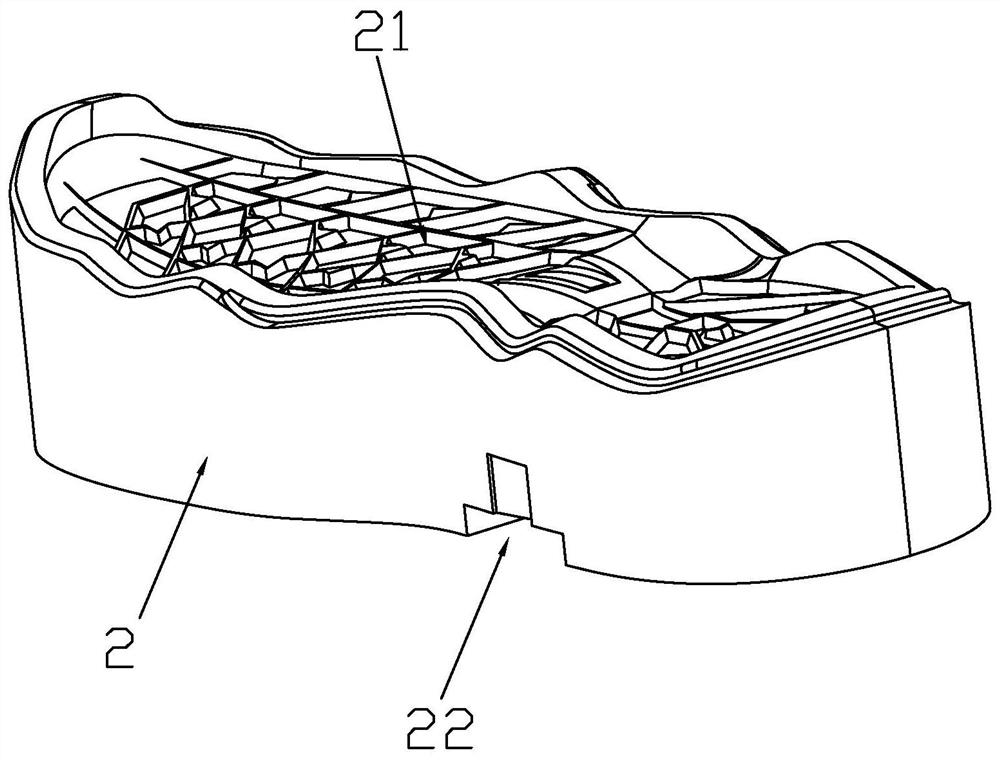

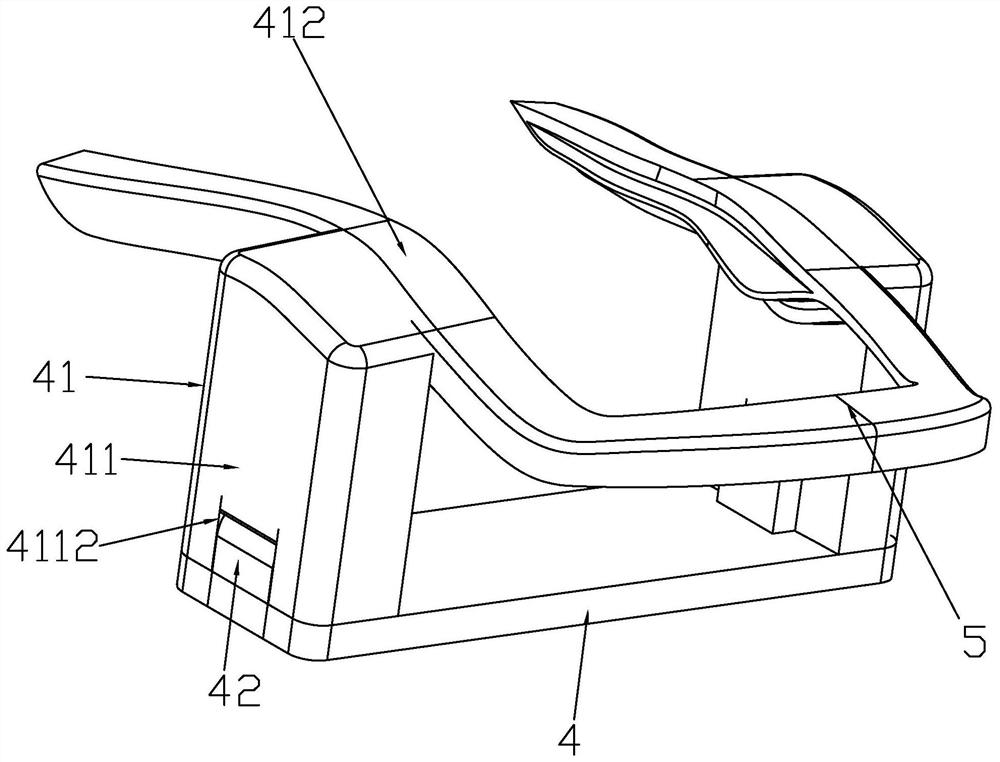

[0026] see Figure 1-Figure 3 Shown: the production mold for double-density and two-color mid-sole shoes, including a mold frame assembly 1, a bottom mold 2 located in the middle of the mold frame assembly 1, a molding cavity 21 is provided in the bottom mold 2, a mold cover 3, and a bottom mold 2 The left and right sides are provided with a skeleton assembly that can be turned by 90°. When the skeleton assembly is turned to a position parallel to the molding cavity 21, a supporting surface 5 is formed for the mold cover 3 to contact with the surroundings of the mold cover 3 when it goes down. There is a through hole under the bottom mold 2. The connection cavity 22 provided, the skeleton assembly includes a connection plate 4 installed in the connection cavity 22, the two ends of the connection plate 4 are respectively hinged with a skeleton plate 41, the skeleton plate 41 includes a hinged part 411 hinged with the connection plate 4 and is arranged on the hinge The other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com