Colored plastic casing and preparation method

A plastic casing and colored technology, applied in chemical instruments and methods, household components, applications, etc., can solve problems such as low yield, poor appearance, and poor layering of film colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

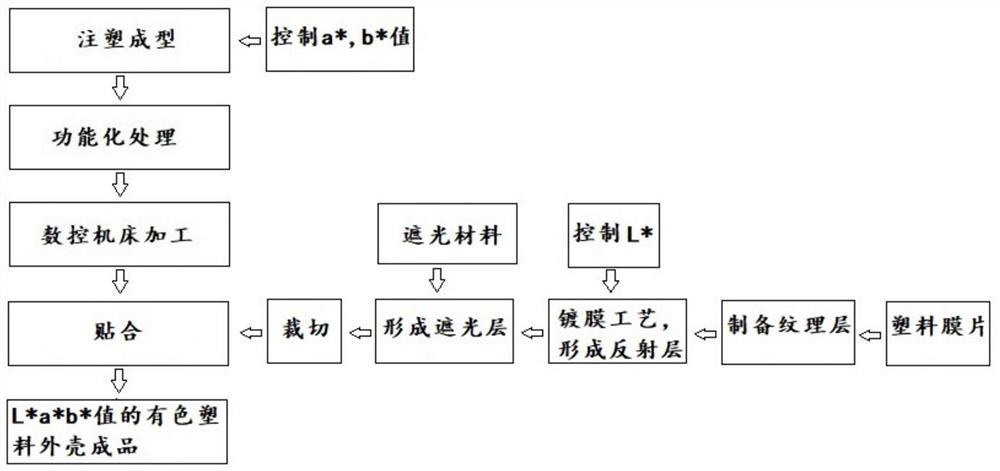

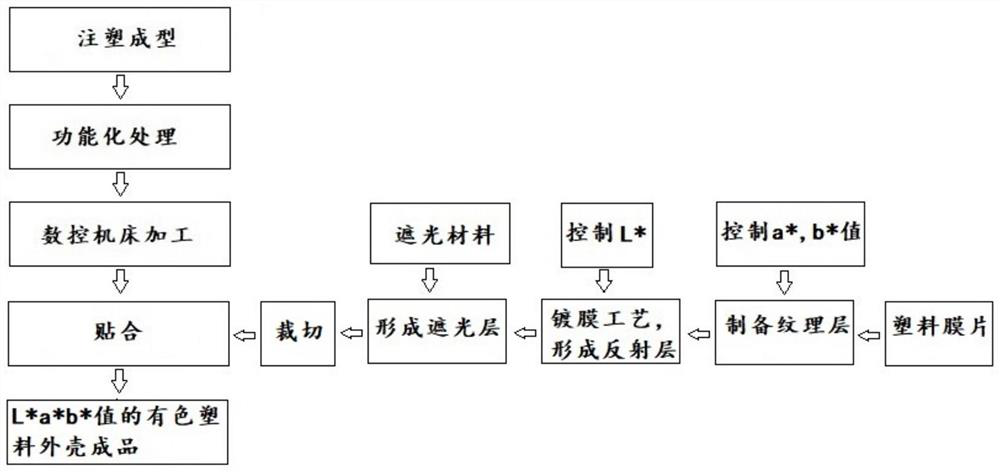

Method used

Image

Examples

specific Embodiment approach 1

[0030] Such as image 3 , 4 As shown in the colored plastic shell, the colored plastic shell 6 sequentially includes a functional coating 3, a shell layer 1, a glue layer 7, a plastic film layer 8, a texture layer 2, a reflective layer 4 and a light-shielding layer 5 from the outside to the inside. The coating 3 is a hardened coating, the thickness of the shell layer 1 is 0.1-5.0mm, and the thickness of the functionalized coating 3 is 2-40um. According to actual needs, the L*a*b* value of the color of the colored plastic shell 6 includes the shell The a*, b* value of the color of the layer 1 or the a*, b* value of the color of the texture layer 2 or the a*, b* value of the color of the glue layer 7 and the L* value of the color of the reflective layer 4. In this embodiment, the thickness of the shell layer 1 is 0.1mm, the thickness of the functional coating 3 is 2um, and the L*a*b* value of the color of the colored plastic shell 6 includes the a*, b* value and the value of th...

specific Embodiment approach 2

[0032] Embodiment 2 is basically the same as Embodiment 1. The setting conditions are basically the same, and the main difference is that in this embodiment, the thickness of the shell layer 1 is 5mm, the thickness of the functional coating 3 is 40um, and the L*a* of the color of the colored plastic shell 6 The b* value includes the a*, b* value of the color of the texture layer 2 and the L* value of the color of the reflective layer 4. At this time, the shell layer is colorless, and the L*a*b* value of the color of the colored plastic shell 6 is set as a whole for blue.

specific Embodiment approach 3

[0034] The setting conditions of the second embodiment and the first embodiment are basically the same, the main difference is: in this embodiment, the thickness of the shell layer 1 is 2.5mm, the thickness of the functional coating 3 is 20um, and the L*a of the color of the colored plastic shell 6 *b* value comprises the a*, b* value of the color of glue layer 7 and the L* value of reflection layer 4 colors, and this moment shell layer, texture layer are colorless, the L*a*b of the color of colored plastic shell 6 * values are set to red overall.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com