Preparation method of plastic mobile phone rear cover

A mobile phone back cover, plastic technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of magnifying appearance defects, no protection measures on the edge of plastic mobile phone back cover, extrusion deformation of explosion-proof film layer, etc., to improve efficiency and product pass-through rate, eliminate appearance defects, and improve the effect of product pass-through rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

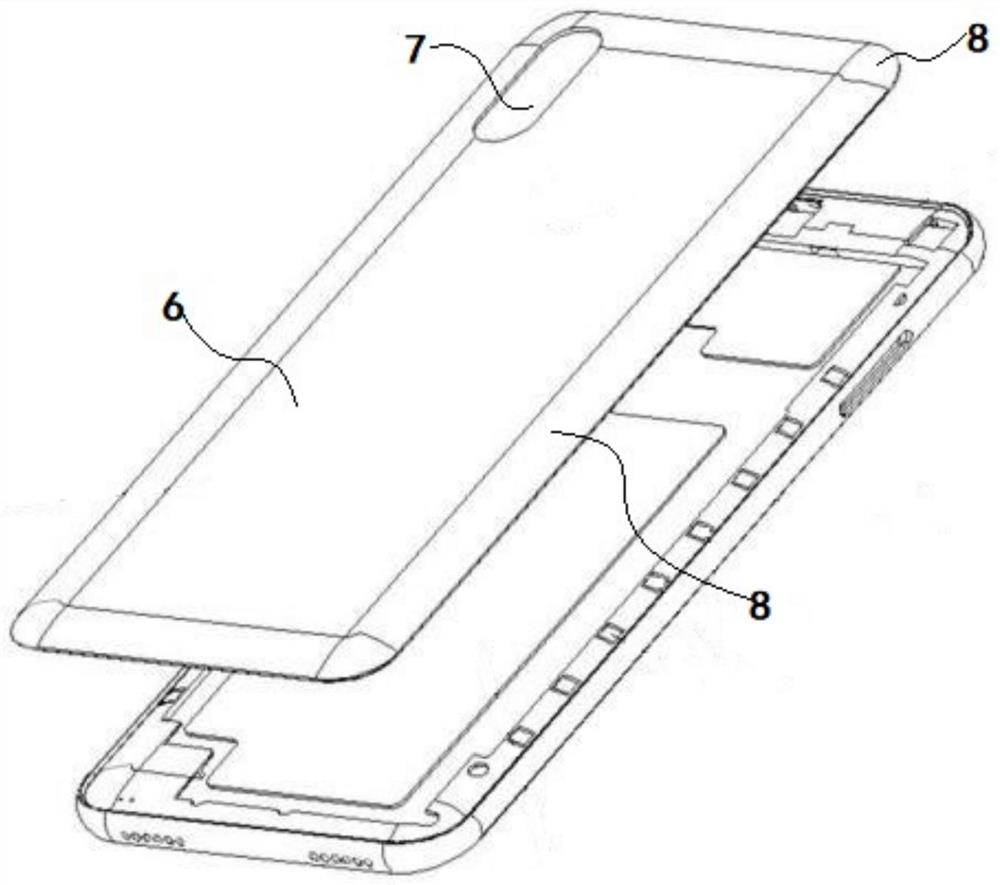

[0030] As shown in the figure, a hole 7 for installing a camera is provided on the plastic mobile phone back cover 6, and four corners and four sides of the plastic mobile phone back cover 6 are provided with reinforcing ribs 8 that are fixedly connected, and the reinforcing ribs 8 and the plastic mobile phone back cover 6. Seamlessly fixed connection or integral molding, the reinforcing ribs 8 provided on the four corners of the plastic mobile phone back cover 6 are rectangular, and the reinforcing ribs 8 provided on the four sides of the plastic mobile phone back cover 6 are in the shape of a "well" as a whole. The reinforcing rib 8 is made of transparent plastic or glass. In this embodiment, the reinforcing ribs 8 and the plastic mobile phone back cover 6 are seamlessly and fixedly connected, and in this embodiment, the reinforcing ribs 8 at the four corners of the plastic mobile phone back cover 6 are rectangular, and the reinforcing ribs 8 on the four sides of the plastic ...

specific Embodiment approach 2

[0032] The main difference between the second embodiment and the first embodiment is:

[0033] (1) In this embodiment, the reinforcing rib 8 and the plastic mobile phone back cover 6 are integrally formed.

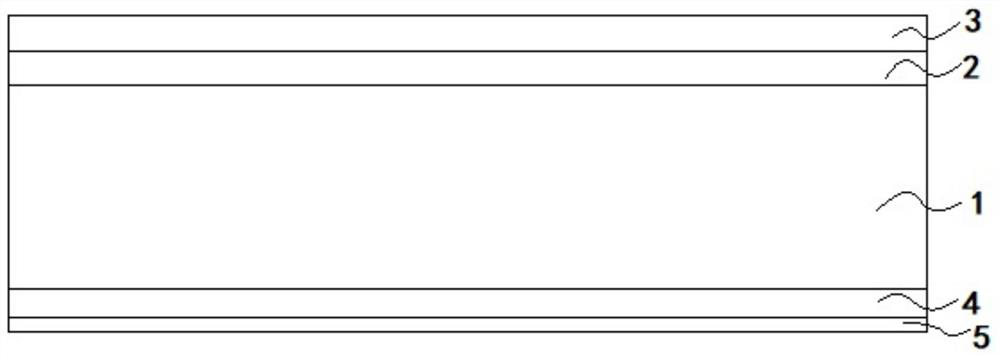

[0034](2) As shown in the figure, in this example, the texture layer 2 is arranged on the inner surface of the outer shell layer 1, that is, in contact with the reflective layer 4; the thickness of the outer shell layer 1 is 5 mm, and the thickness of the functionalized coating layer 3 is 40 μm.

specific Embodiment approach 3

[0035] The main difference between the third embodiment and the first embodiment is:

[0036] (1) In this embodiment, the reinforcing rib 8 and the plastic mobile phone back cover 6 are integrally formed.

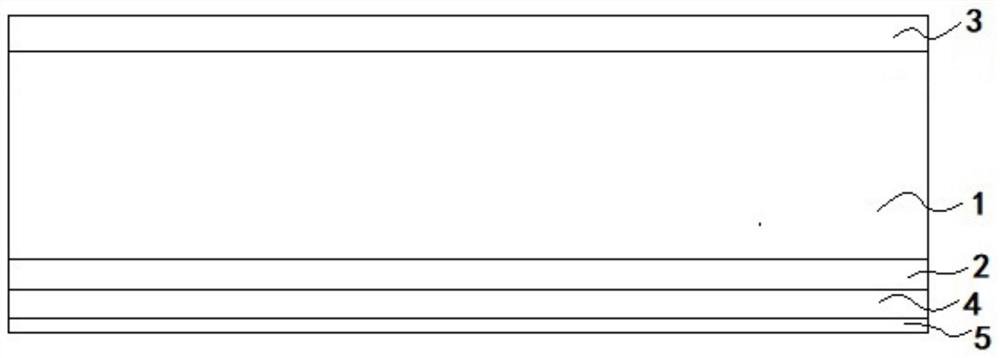

[0037] (2) As shown in the figure, in this example, the texture layer 2 is arranged on both sides of the outer shell layer 1, that is, the texture layer 2 is in contact with the reflective layer 4 and the hardened coating layer 3 respectively; the thickness of the outer shell layer 1 is 2.5mm, The thickness of the functionalized coating 3 is 20um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com