Method for detecting frosting state of heat exchanger through temperature and humidity sensors

A humidity sensor and heat exchanger technology, which is applied in mechanical equipment, heating and ventilation control systems, heating and ventilation safety systems, etc., can solve problems such as incomplete defrosting, poor prediction effect, and reduced heat exchange capacity, so as to avoid The effect of incomplete defrosting, simple and convenient application, and clear state logic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

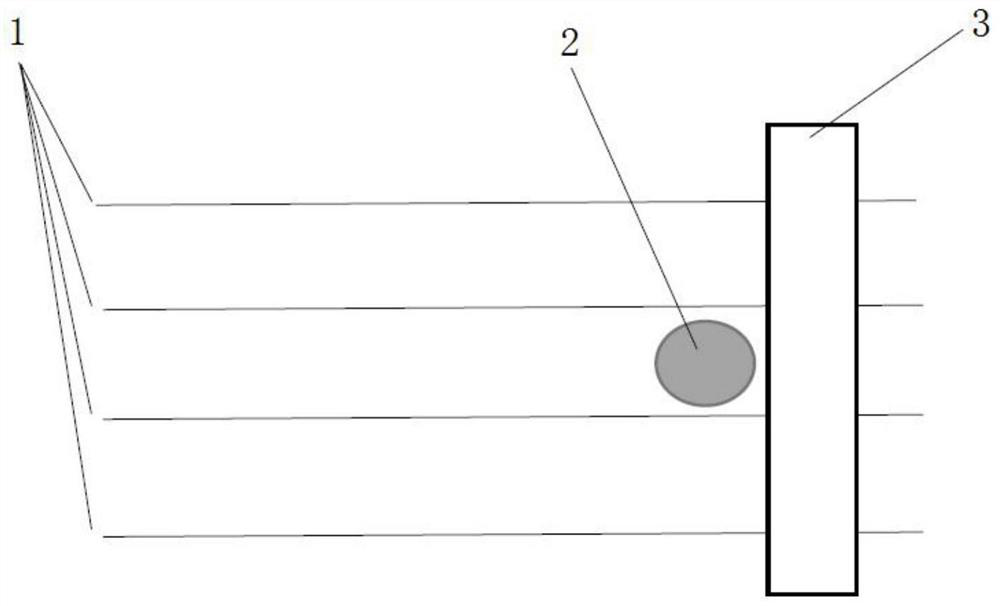

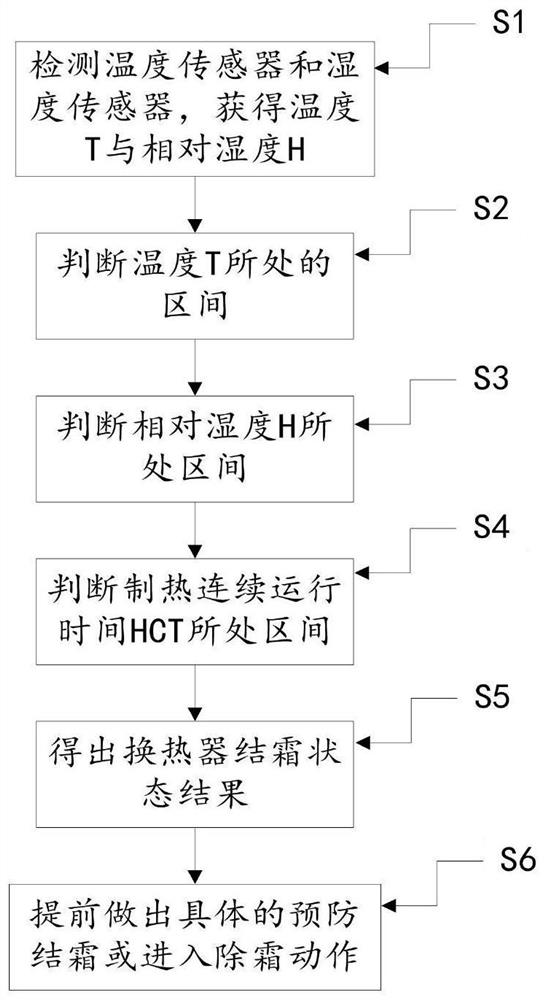

[0050] refer to figure 1 , a method for temperature and humidity sensors to detect the frosting state of a heat exchanger, based on the temperature sensor, humidity sensor 2, and water vapor dew point temperature, the temperature sensor and humidity sensor 2 are placed next to the coil 3, and the fins of the heat exchanger 1 In the middle position, the temperature T and relative humidity H of the fins of the heat exchanger are detected by the temperature sensor and the humidity sensor, combined with the heating continuous running time HCT of the unit, the above parameters are compared and analyzed with the corresponding preset threshold parameters. The setting thresholds include temperature threshold T1, temperature threshold T2, temperature threshold T3, humidity threshold H1, humidity threshold H2, heating continuous running time threshold HCT1, heating continuous running time threshold HCT2, real-time acquisition of heat exchanger through temperature sensor and humidity sens...

Embodiment 2

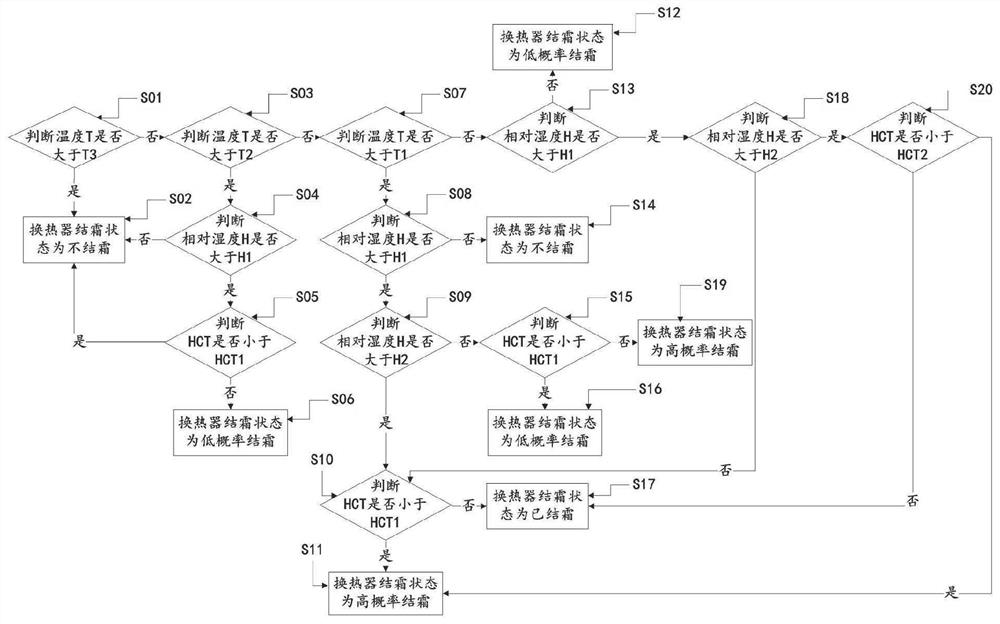

[0060] refer to image 3 A method for detecting the frosting state of a heat exchanger with a temperature and humidity sensor, comprising the steps of:

[0061] S01: judge whether the temperature T is greater than T3, if the judgment result is yes, turn to S02, if the judgment result is no, turn to S03;

[0062] S02: The frosting state of the heat exchanger is no frosting;

[0063] S03: judge whether the temperature T is greater than T2, if the judgment result is yes, turn to S04, if the judgment result is no, turn to S07;

[0064] S04: judge whether the relative humidity H is greater than H1, if the judgment result is yes, turn to S05, if the judgment result is no, turn to S02;

[0065] S05: judge whether HCT is less than HCT1, if the judgment result is yes, turn to S02, if the judgment result is no, turn to S06;

[0066] S06: The frosting state of the heat exchanger is low-probability frosting;

[0067]S07: judge whether temperature T is greater than T1, if the judgment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com