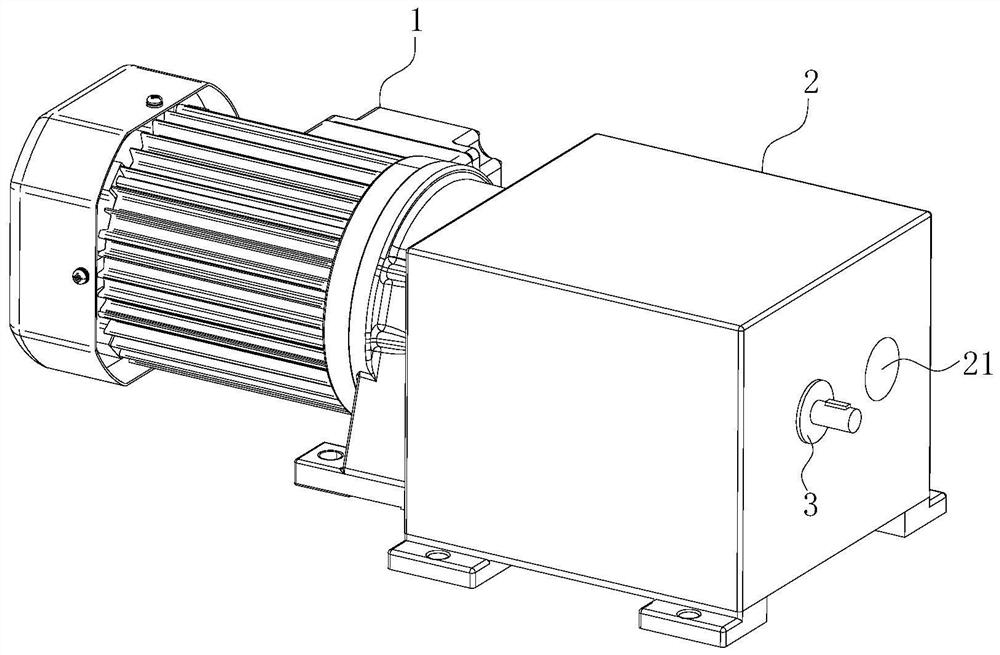

Asynchronous motor

A technology for asynchronous motors and motor bodies, applied in electromechanical devices, electrical components, mechanical equipment, etc., can solve the problems of large starting current of motors, increase the capacity of power supply transformers, waste electricity, etc., achieve automatic torque adjustment and avoid overload operation , the effect of solving the demand for capacity expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

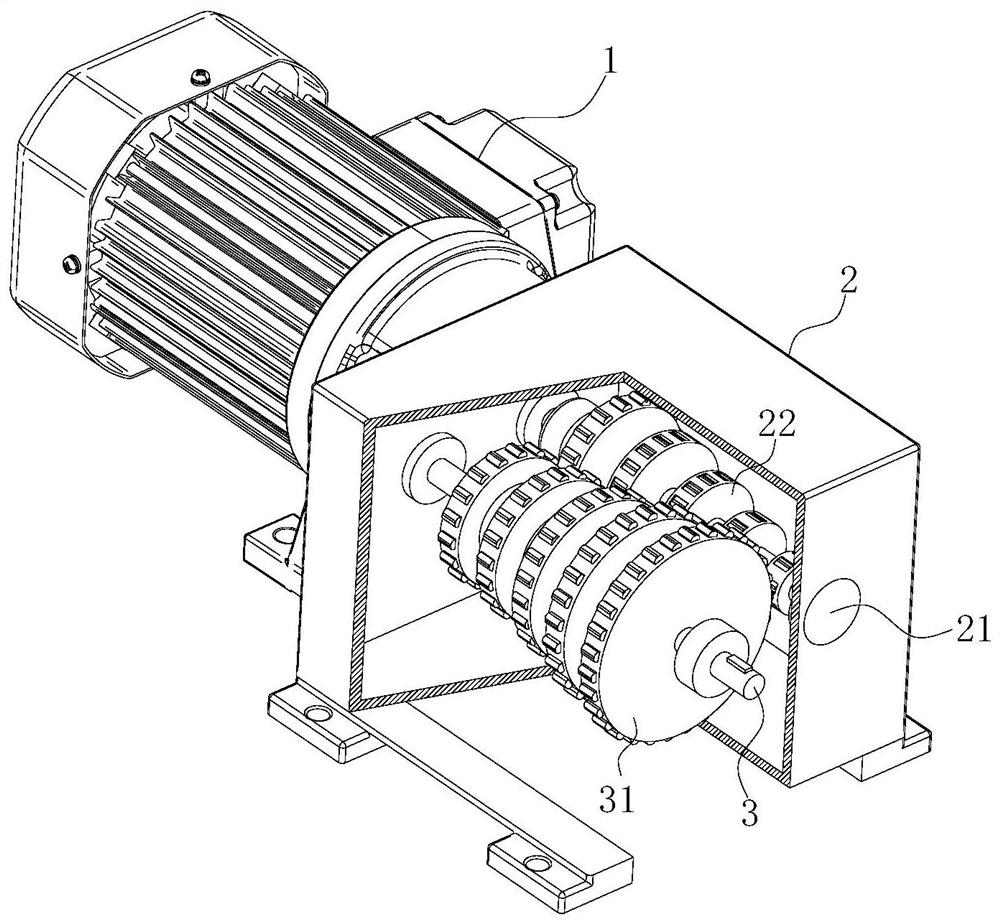

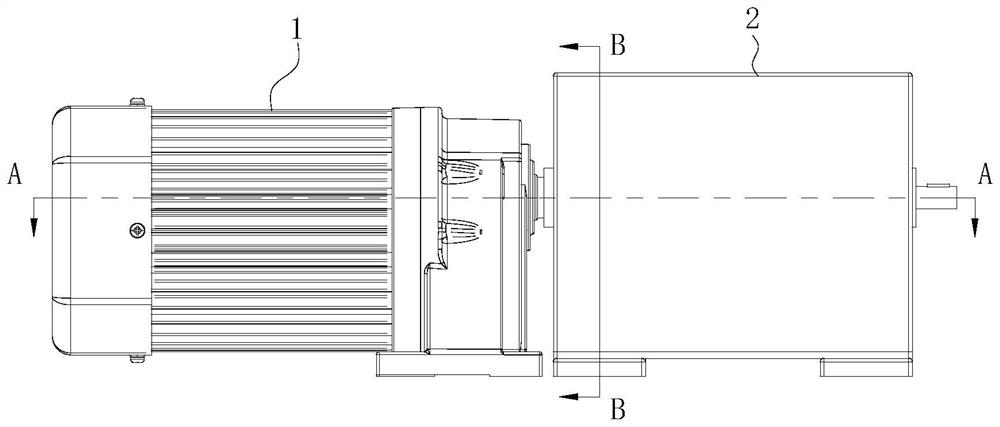

[0028] As an embodiment of the present invention, the first tooth 23 is provided with a first rotating groove at a position on the side of the side away from the corresponding second alveolar bottom; A rotating column 24; the second tooth 32 is deviated from the side of the side corresponding to the second alveolar bottom, and a second rotating groove is provided; the inside of the second rotating groove is connected with a second rotating column 33 During work, by rotating the first rotating column 24 on the surface of the first tooth 23, rotating and connecting the second rotating column 33 on the surface of the second tooth 32, by the rotation of the first rotating column 24 and the second rotating column 33, When switching between the first transmission disc 22 and the second transmission disc 31 with different transmission ratios, the direct collision between the first gear 23 and the second gear 32 is avoided, so that the first gear 23 slides quickly into the position bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com