Valve element of butterfly valve

A butterfly valve, valve core technology, applied in the direction of lift valve, valve device, engine components, etc., can solve the problems of increased friction and increased rotational torque, achieve roughly uniform rigidity, improve rigidity, and improve sealing stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

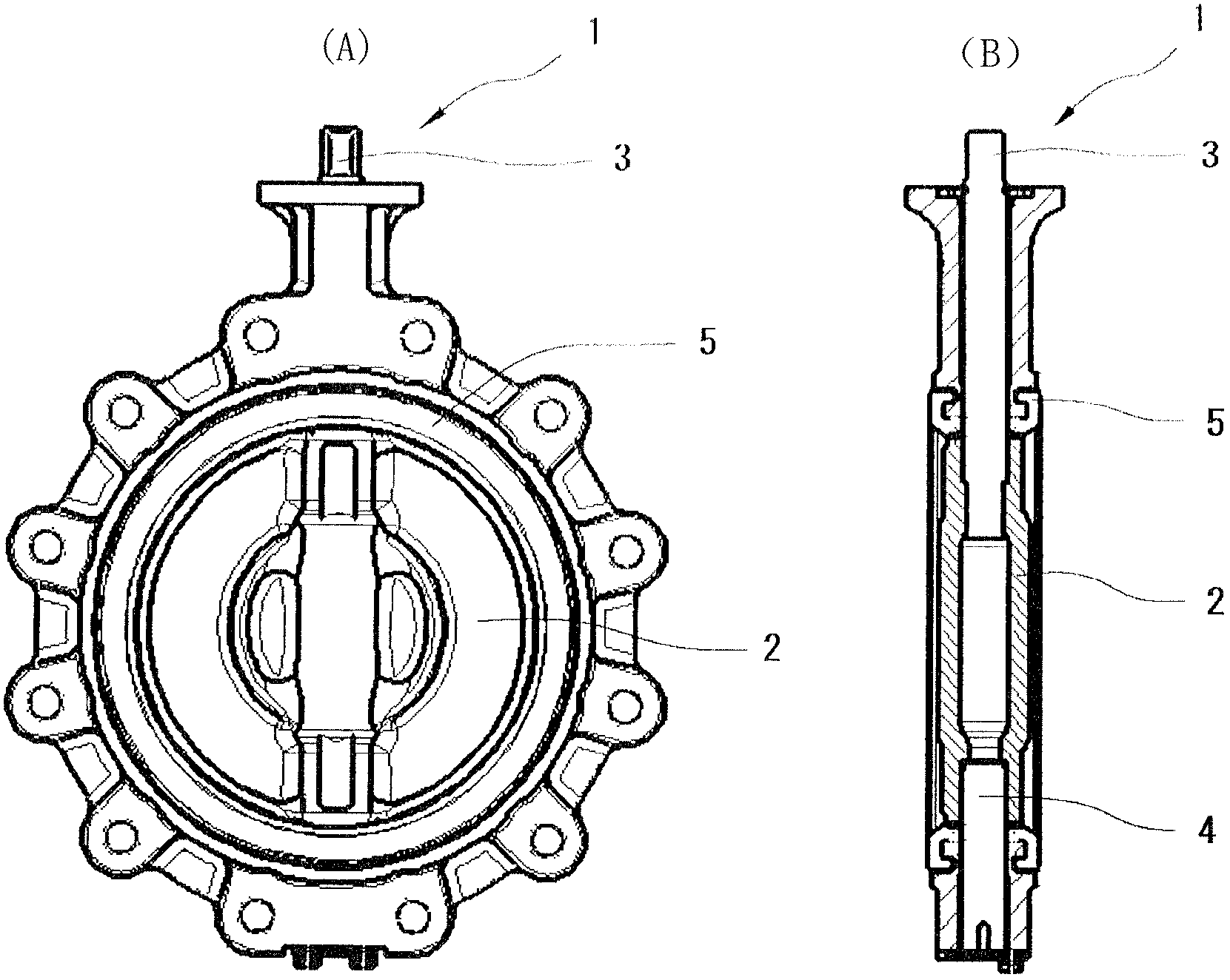

[0028] Embodiments of the present invention will be described below using the drawings. figure 1 The reference number (1) in the figure is the main body of the butterfly valve, which has a hollow cylindrical flow path, and is supported by the valve stem (3), (4) to rotate freely. The hollow cylindrical flow path is opened and closed. A seat ring (5) made of elastic body is installed on the inner peripheral surface of the hollow cylindrical part of the valve body (1), so that the outer peripheral surface of the valve core (2) contacts the seat ring (5) and leaves the seat ring (5). , to open and close the valve.

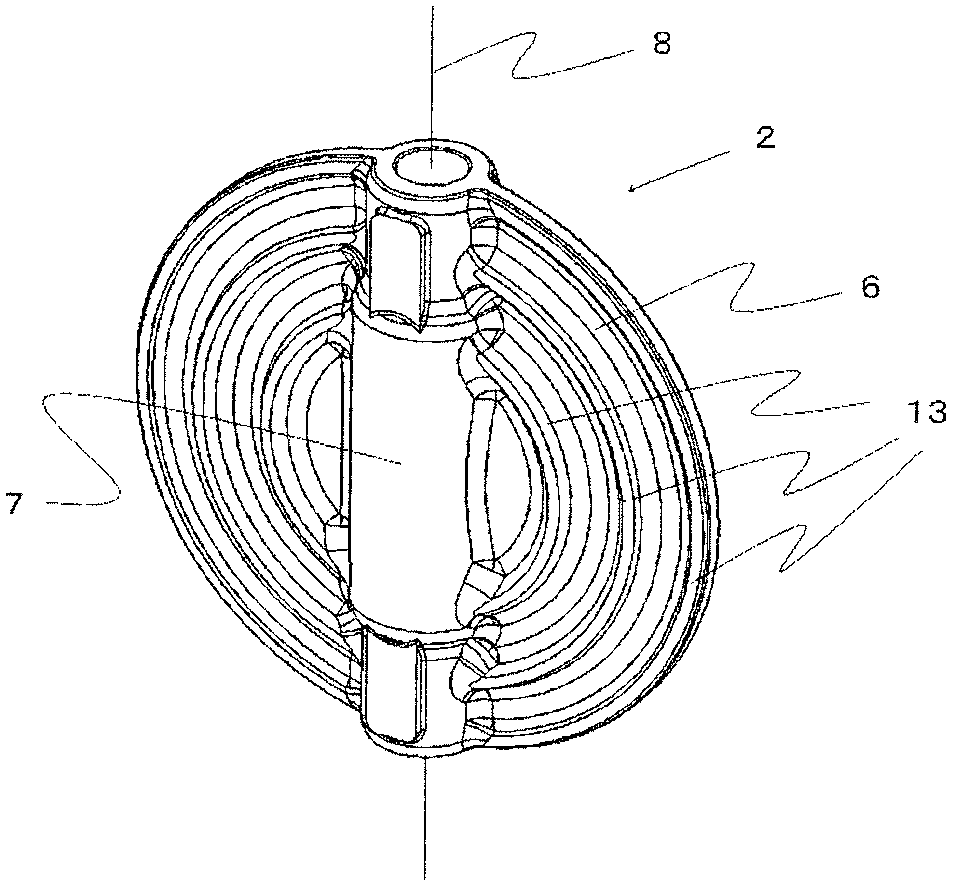

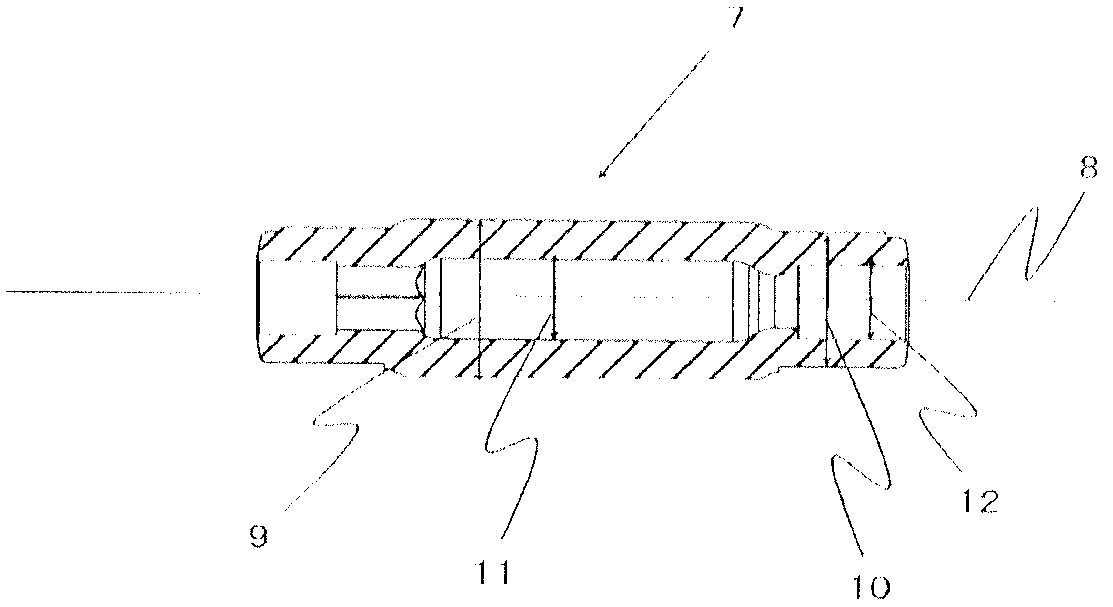

[0029] refer to figure 2 , the valve core (2) is composed of a disc-shaped base plate (6), and has a cylindrical part (7) for inserting the valve stem in the center of the base plate (6). The cylindrical portion ( 7 ) has a shape that bulges from the front and back of the substrate ( 6 ). The shape of the cylindrical portion ( 7 ) can increase the section coeffic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com