Wire-following frame of universal chassis

A wire rack and chassis technology, applied in the field of general chassis and wire racks, can solve the problems of increased design difficulty and difficult realization, and achieve the effect of stable performance and high generalization coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and examples.

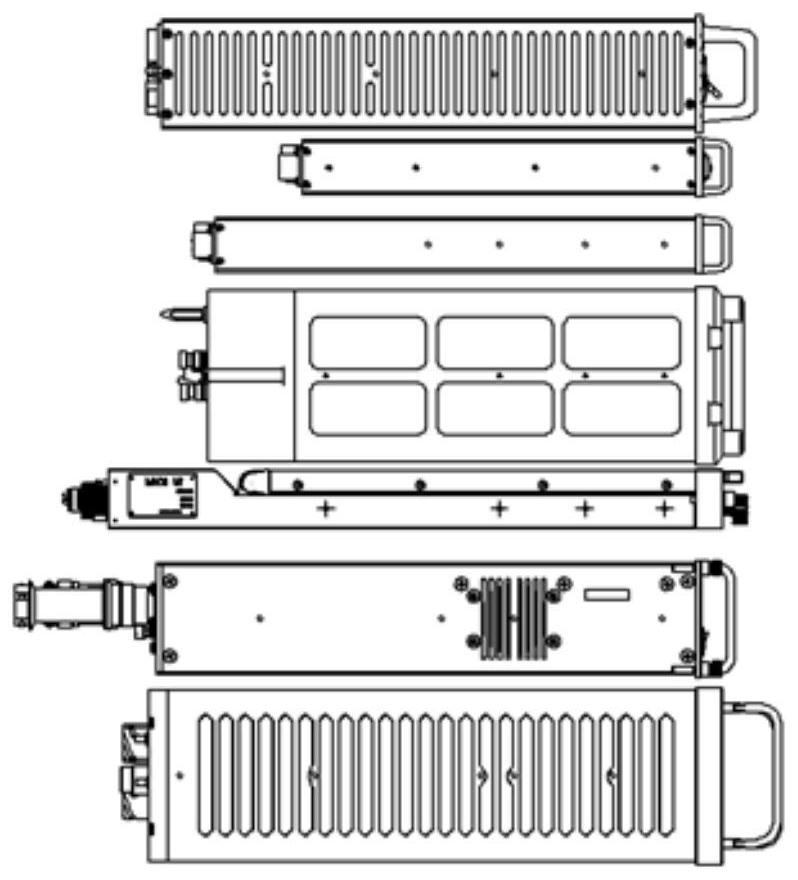

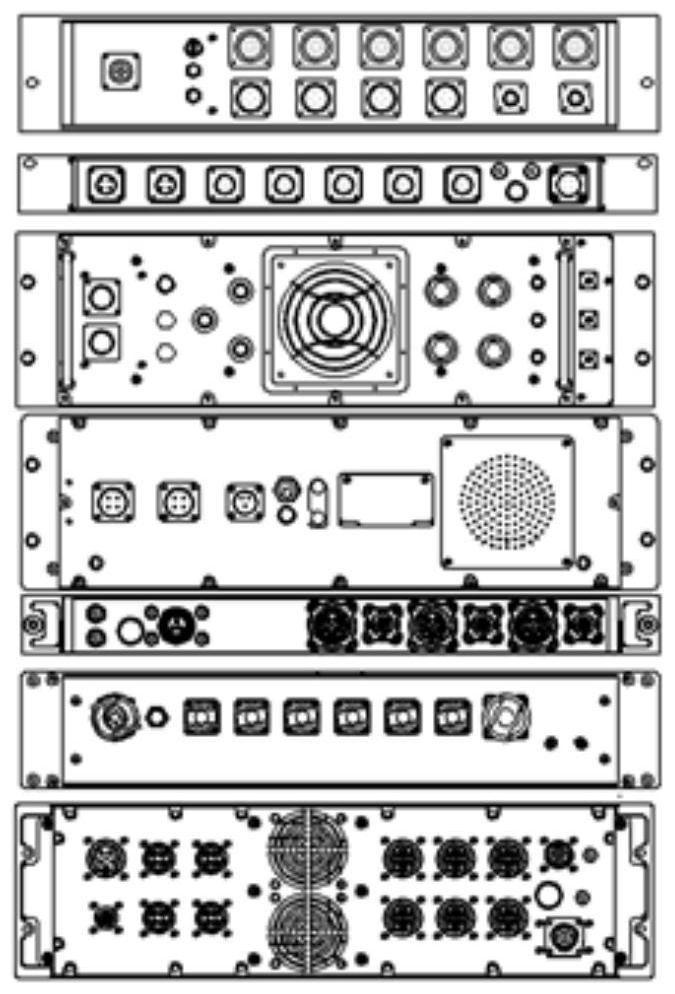

[0023] This embodiment provides a universal chassis and cable rack, which is suitable for chassis with different functions, different dimensions, and different installation interfaces, and can effectively fix cables in different chassis, with high generalization coefficient and stable performance.

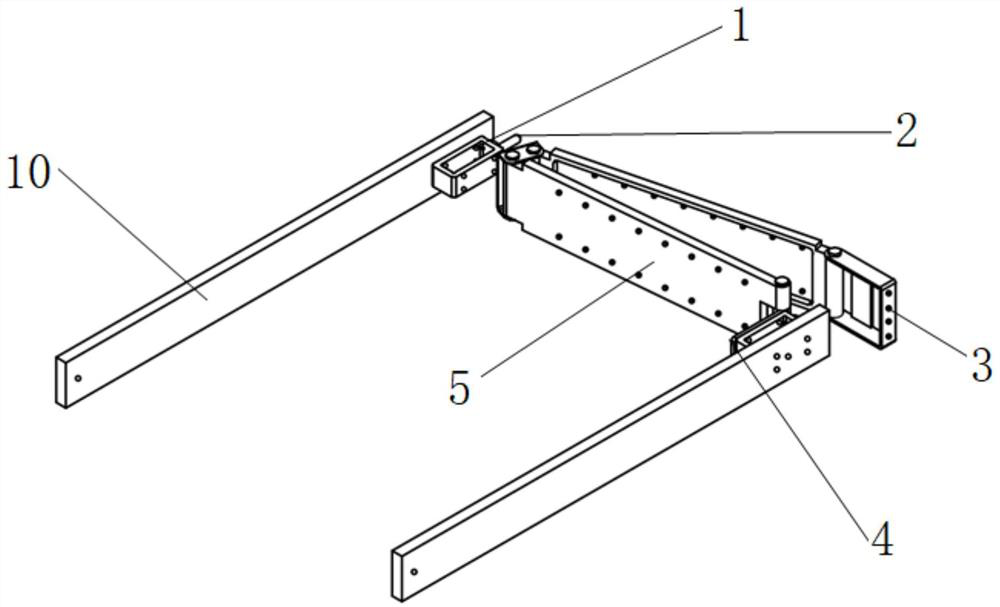

[0024] Such as image 3 and 4 As shown, the chassis follower includes: fixing piece 1, positioning pin 2, follower base I3, follower base II4, wiring board I5, wiring holder connector 6 and wiring board II11.

[0025] The connection relationship between the cabinet and the wire rack is as follows: inner guide rails 10 are respectively arranged on both lateral sides inside the cabinet, and fixing parts 1 (such as Figure 5 shown), one end of the wiring board I5 and the wiring board II11 are respectively fixed and installed on the fixing piece 1 on the lateral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com