Water-sealed tank

A water-sealing tank and water-sealing technology, applied in valve devices, mechanical equipment, engine components, etc., can solve problems such as fluctuation of sealing water, inability of sealing water to play a sealing role, and large-pulse combustion of torches, so as to reduce the water sealing level difference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

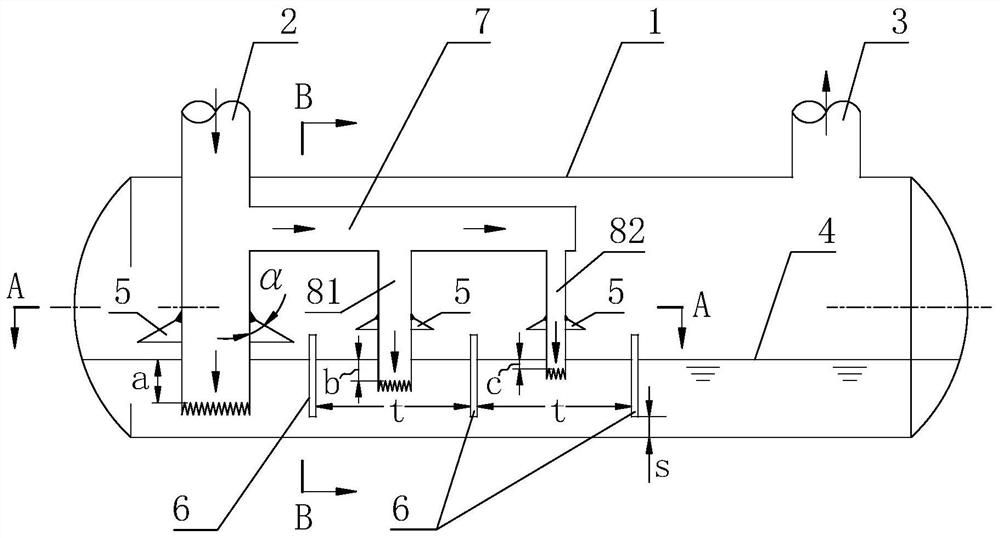

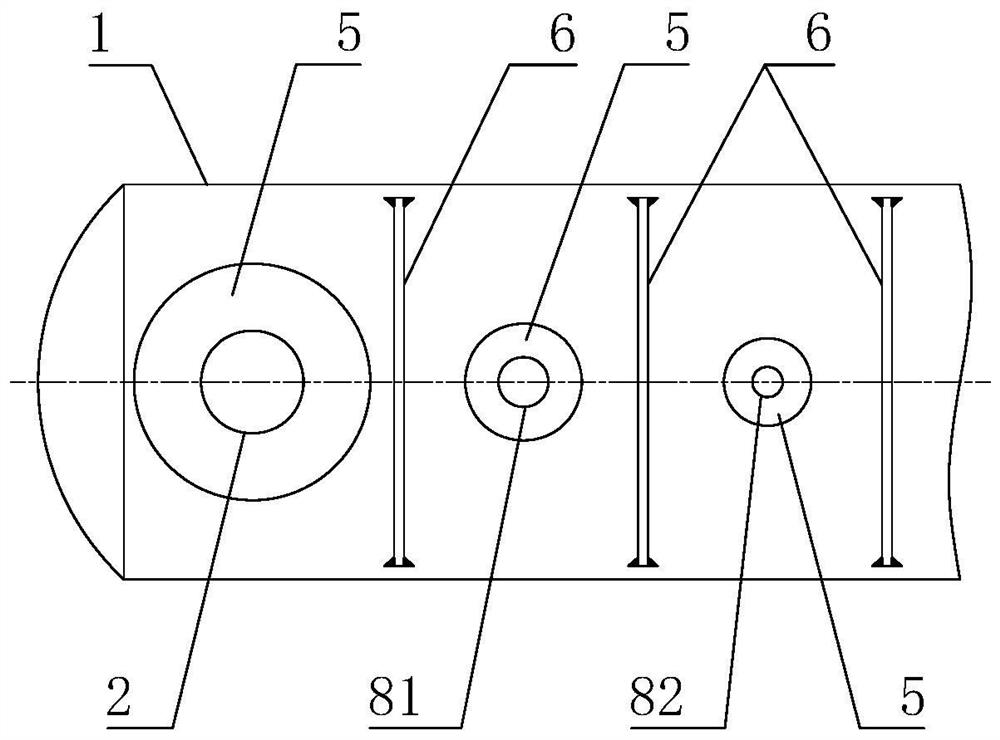

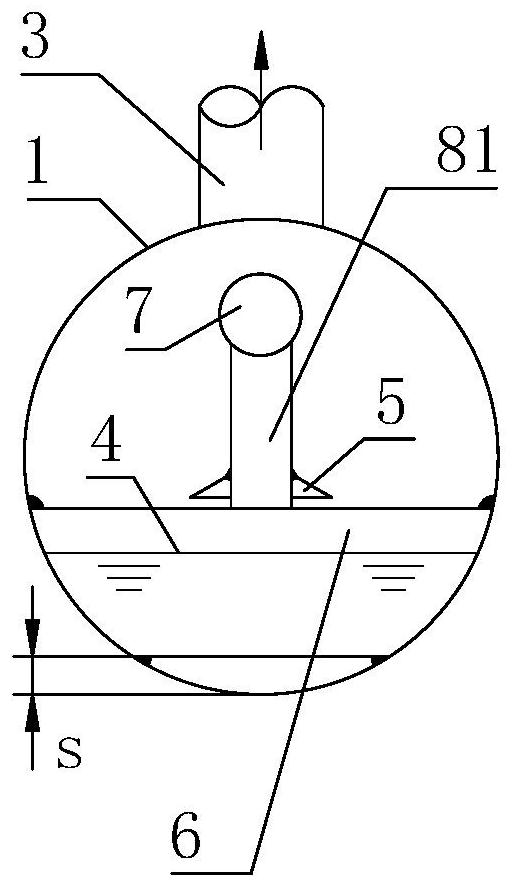

[0016] see figure 1 , figure 2 and image 3 , A water-sealed tank of the present invention is provided with a horizontal tank body 1, and the two ends of the horizontal tank body 1 are respectively provided with a main pipe 2 for the inlet of the torch exhaust gas and a pipeline 3 for the outlet gas of the torch exhaust gas. The main pipeline 2 of the flare exhaust gas inlet is arranged vertically, and the top inlet is connected with the process device. The outlet of the flare exhaust gas outlet pipeline 3 is connected with the flare. The bottom of the horizontal tank body 1 is equipped with sealing water, the upper surface of the sealing water is the sealing water liquid level 4, and the top of the sealing water liquid level 4 is the gas phase space.

[0017] Horizontal tank body 1 is provided with an auxiliary pipe main pipe 7 along the axial direction of horizontal tank body 1, one end of auxiliary pipe main pipe 7 is connected with main pipe 2 of flare exhaust gas inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com