Charging bucket-weighing and differential pressure-compensating system for serial-type bell-less top

A technology of compensation system and material-less bell, which is applied in the direction of furnace, blast furnace, blast furnace details, etc., can solve problems such as inaccurate weighing value of material tank, and achieve the effect of improving smelting level, precise control, stable and reliable control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

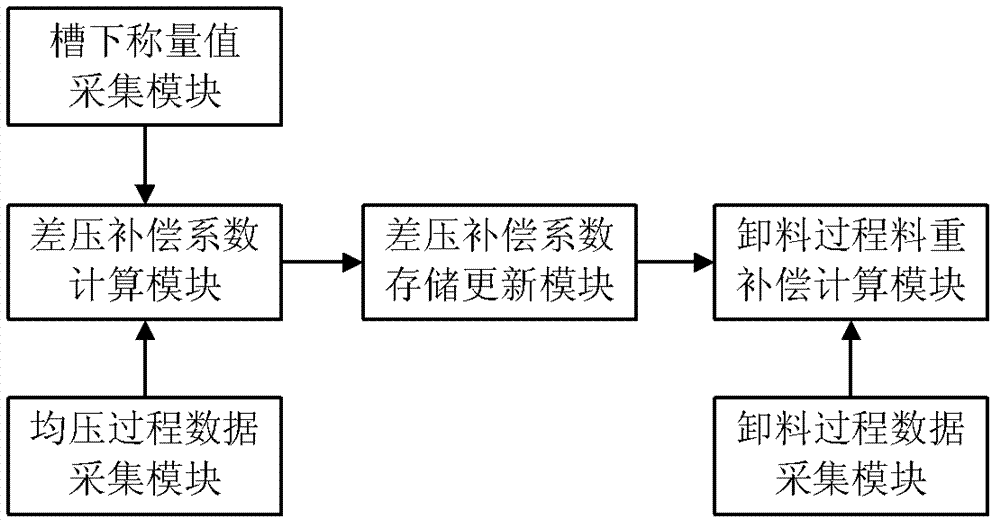

[0035] The tank weighing differential pressure compensation system on the top of the bell-less furnace provided by the invention has a structure as follows: figure 1Shown: Including the weighing value acquisition module under the tank, the differential pressure compensation coefficient calculation module, the pressure equalization process data acquisition module, the differential pressure compensation coefficient storage update module, the unloading process data acquisition module, the unloading process material weight compensation calculation module, They are connected by electrical signals.

[0036] Under-tank weighing value acquisition module: used to read the weighing value W of the blast furnace under-tank weighing measurement system after each tank is filled 槽下 .

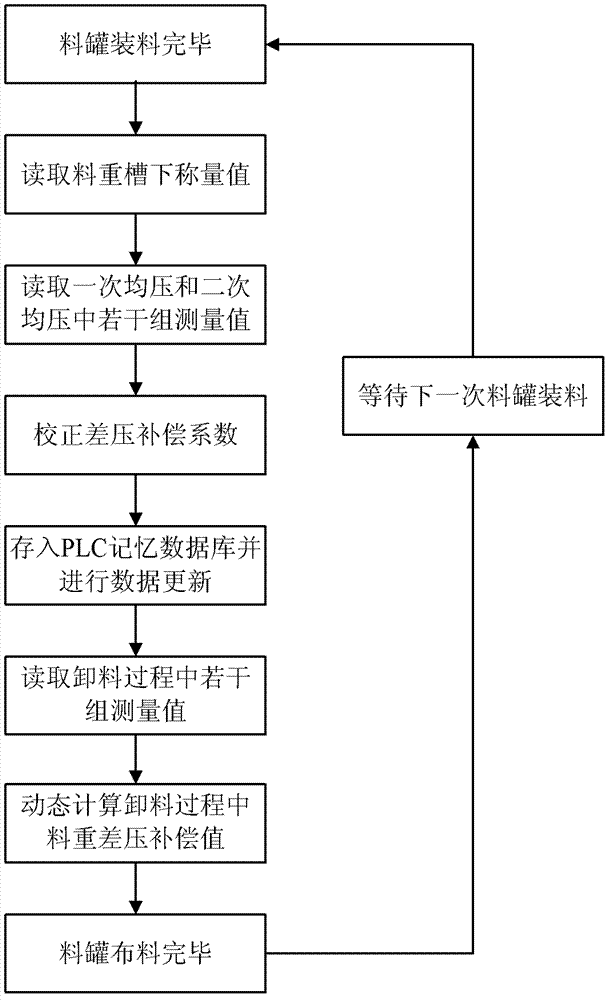

[0037] Data acquisition module for pressure equalization process: used to read multi-group material weight W in batches during the primary pressure equalization and secondary pressure equalization process of ...

Embodiment 2

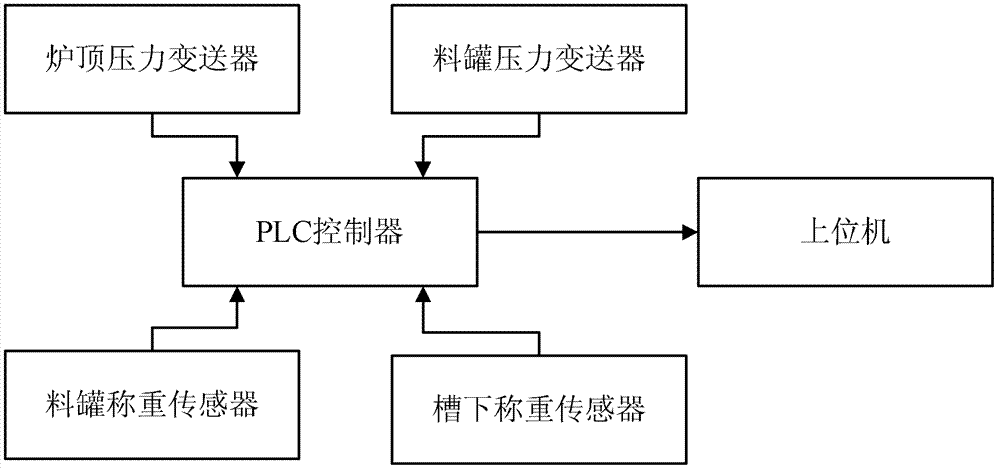

[0077] The tank weighing differential pressure compensation system on the top of the furnace with a string of tanks without a bell provided by the present invention has a hardware system structure as follows: image 3 Shown: It is composed of PLC controller, furnace top pressure transmitter, material tank pressure transmitter, material tank weighing sensor, tank weighing sensor and upper computer. The PLC controller receives the process data sent from the on-site weighing sensor and pressure transmitter, performs data analysis and online calculation according to the method of the present invention, continuously corrects the differential pressure compensation coefficient of the tank weighing, and converts the corrected difference The pressure compensation coefficient is stored in the memory database of the PLC controller and displayed in the host computer at the same time.

[0078] The tank weighing differential pressure compensation system for the above-mentioned series tank w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com