Trough type water culture device with water draining and residue filtering mechanism

A technology of hydroponic device and filter residue, applied in cultivation, soilless cultivation, filter circuit and other directions, can solve the problems of inability to effectively control the liquid level, affecting the service life, affecting the growth of crops, etc., so as to be beneficial to the growth of crops and slow down the circulation of water flow. speed and longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

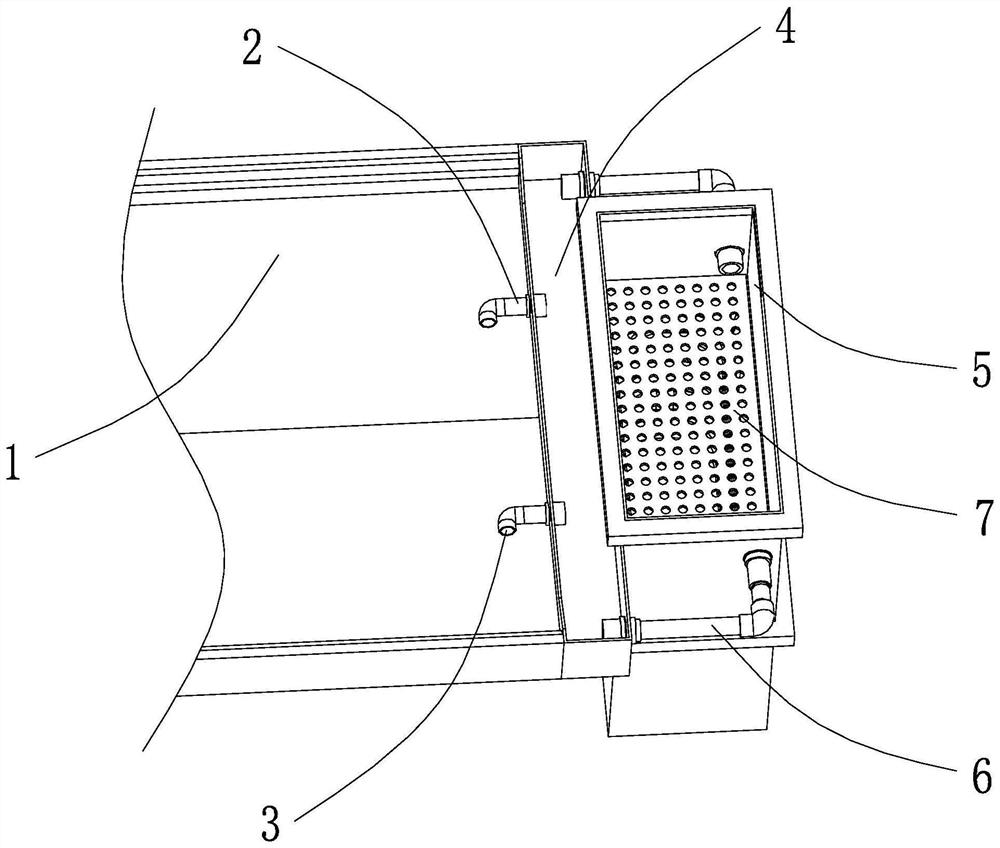

[0017] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0018] see figure 1 As shown, the above-mentioned trough-type hydroponic device with a drainage filter residue mechanism includes a water tank 1 with a water inlet and a drain outlet, a drainage filter residue mechanism communicated with the drain outlet, and a return pump communicated with the water inlet (not shown in the figure) ). The return water pump communicates with the drainage filter residue mechanism, and is used to pump the drainage into the water inlet, so as to realize the circulating water supply to the water tank 1 .

[0019] The drainage filter mechanism includes a first pipeline 2 coaxially penetrated in the drain outlet, and a second pipeline 3 communicating with the first pipeline 2 and located in the water tank 1 . The outer diameter of the first pipeline 2 is the same as the inner diameter of the water outlet, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com