Automatic locking device for three-piece type hoop flange

An automatic locking and clamping flange technology, which is applied in the direction of pressure vessels, fixed-capacity gas storage tanks, mechanical equipment, etc., can solve a large amount of manpower and time for clamping and locking, and the opening and closing efficiency of the pressure cylinder end cover is not enough Fully reflect other issues, to achieve the effect of improving the degree of safety protection, liberating the labor force, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific structure and implementation process of this solution will be described in detail below through specific embodiments and accompanying drawings.

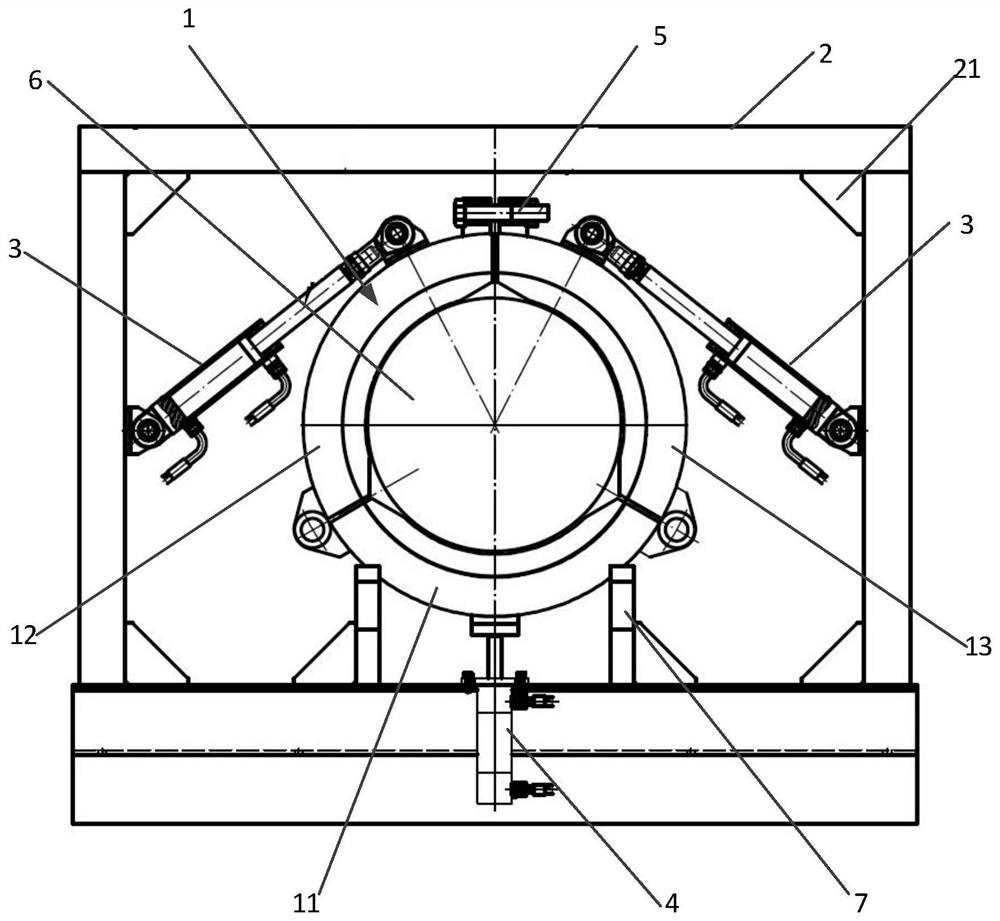

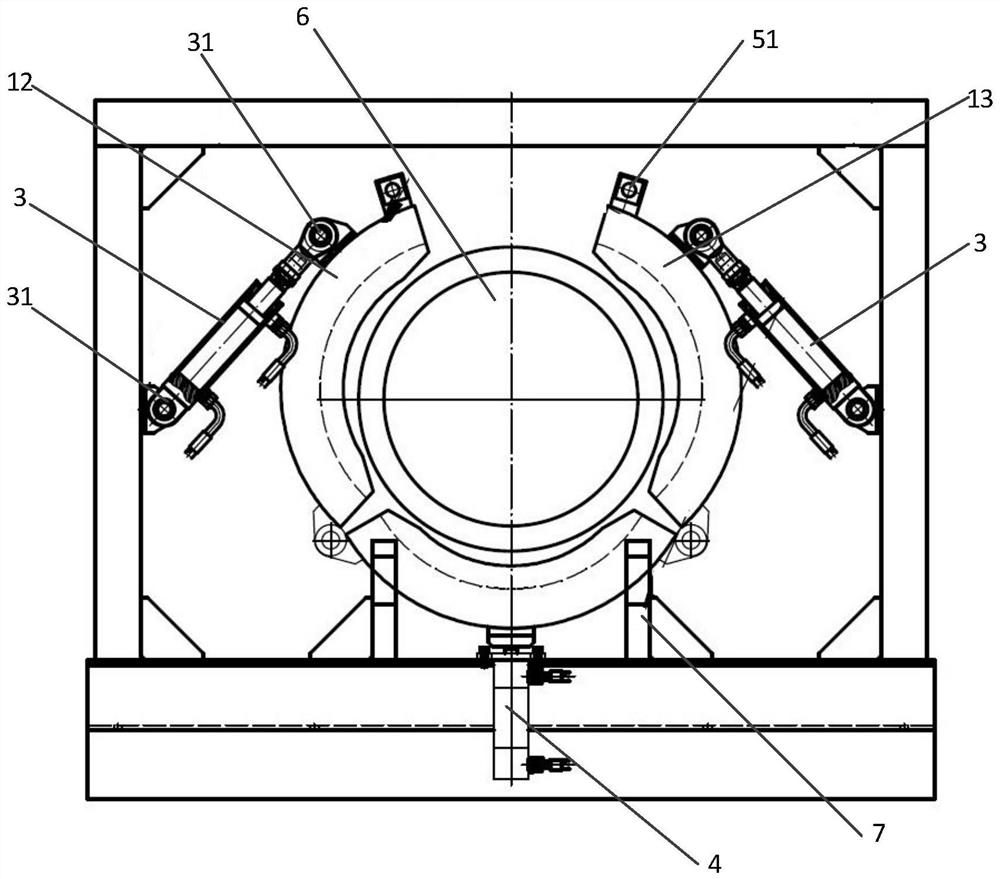

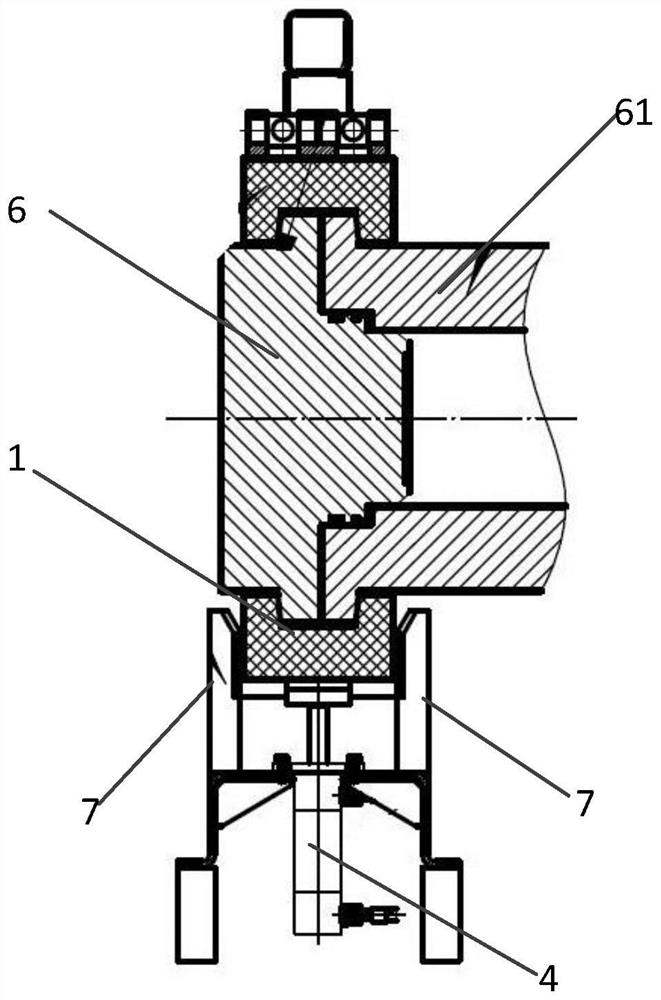

[0015] Such as figure 1 , 3 As shown, in one embodiment of the present invention, an automatic locking device for a three-piece clamp flange is disclosed, wherein the three-piece clamp flange 1 includes left hoops that are connected to each other to form a ring 12. The right hoop 13 and the bottom hoop 11, the left hoop 12 and the right hoop 13 are respectively axially connected to both ends of the bottom hoop 11 through one end, and the three are used to fix the pressure cylinder port 61 and the pressure cylinder end cover 6 together after being connected. .

[0016] The automatic locking device includes an outer frame reaction force frame 2, a clamping oil cylinder 3, a jacking oil cylinder 4 and a locking bolt 5.

[0017] The outer frame reaction frame 2 is a rectangular frame, which is set on the periphery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com