Pneumatic control valve device, pneumatic control valve group and pneumatic control assembly

A technology of pneumatic control valve and valve body, applied in the field of pneumatic control valve device and pneumatic control assembly, can solve the problems of low life, inconvenient maintenance, inconvenient use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

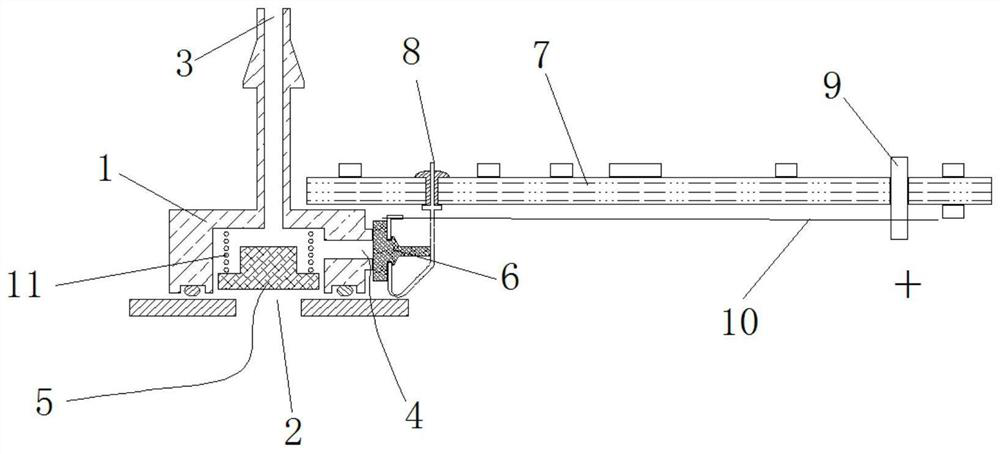

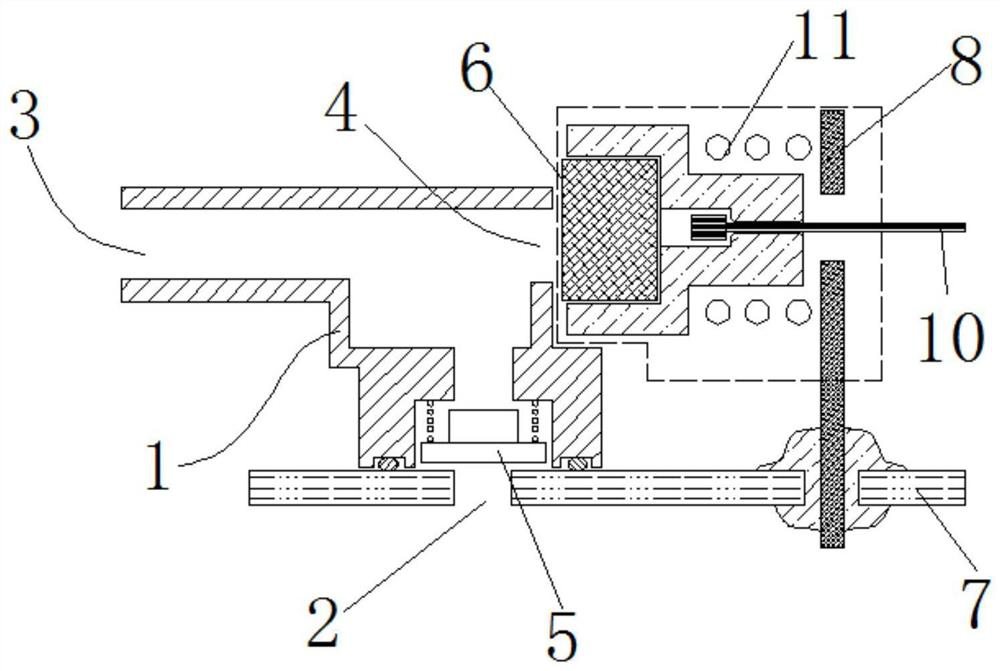

[0023] A pneumatic control valve device, comprising: a hollow valve body 1, an elastic component 6 and an electric control module;

[0024] The valve body 1 is provided with an air intake passage 2, an inflation passage 3, and an exhaust passage 4 communicating with the outside, and a check valve 5 is provided in the air intake passage 2; the air intake passage 2 is used to introduce gas, The inflation passage 3 is used to supply air to the pneumatic cavity 14; the elastic component 6 is arranged on the end of the air leakage passage 4 communicating with the outside;

[0025] The electric control module includes: a circuit board 7, an elastic first electrode 8 and a memory alloy wire 10 connected to the first electrode 8; one end of the first electrode 8 is connected to the elastic component 6, and the first electrode The other end of 8 is electrically connected to the circuit board 7; the end of the memory alloy wire 10 away from the first electrode 8 is electrically connecte...

Embodiment 2

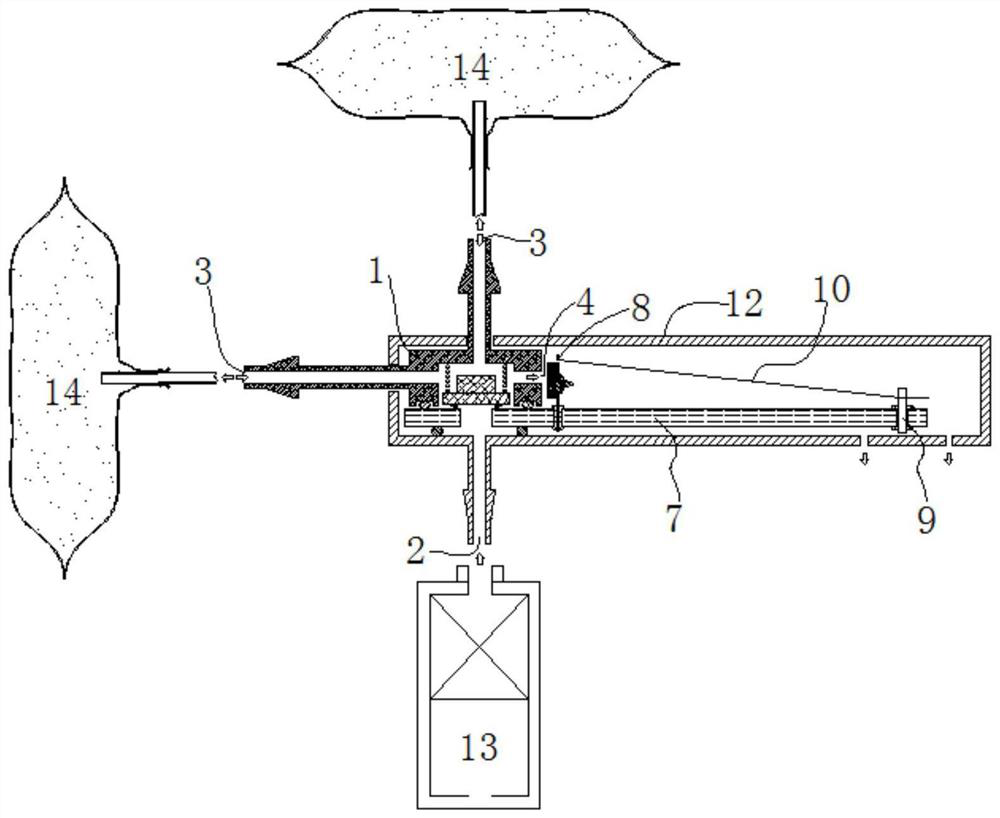

[0045] A pneumatic control valve group, including a pneumatic control valve device; the pneumatic control valve group includes: at least two of the pneumatic control valve devices; the circuit board 7 is electrically connected to the at least two pneumatic control valve devices respectively connect.

[0046] Such as Figure 5 As shown, two or more pneumatic control valve groups can be set to form a plurality of air circuit control linkage coordination mechanisms; wherein, the memory alloy wire can be bent and adjusted through the structural guide post 15 (one or more), and Adjustment of the wire length is thus obtained.

[0047] A pneumatic control assembly includes the aforementioned pneumatic control valve group; and also includes: an air pump 13 connected to the air intake passage 2 and a pneumatic chamber 14 connected to the inflation passage 3 . In this embodiment, a pneumatic control assembly may further include an auxiliary structure such as an air pipe connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com