Anti-falling pipe joint

A technology for inner tubes and ends, which is applied in the field of pipe joints to prevent falling off, and can solve problems such as inconvenient and quick disconnection of butt joints and unsatisfactory sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

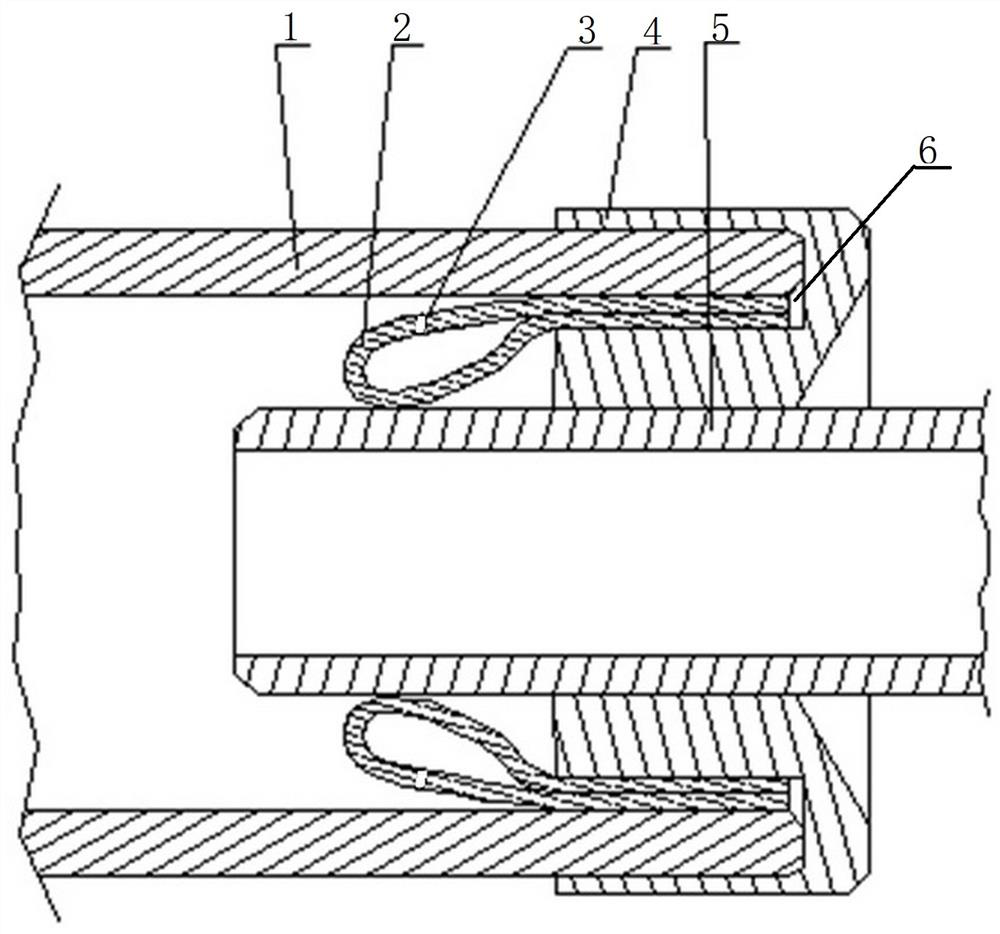

[0008] A pipe joint that prevents falling off, such as figure 1 As shown, it includes an outer tube 1 and an inner tube 5. The inner tube 5 is sleeved in a gland 4, and an annular groove 6 is arranged in the end surface of the gland 4 facing the end of the inner tube. A cylindrical cylindrical sealing bag 2 is set on the inner peripheral wall of the groove 6, and the inner surface of the outer end of the cylindrical cylindrical sealing bag 2 is attached to the outer peripheral wall of the end of the inner tube, and the end of the outer tube 1 is also fitted in the In the annular groove 6, the inner peripheral wall of the end of the outer tube 1 is in sealing contact with the outer peripheral surface of the cylindrical sealed bag 2, and is located at the inner side of the gland 4, the end of the inner tube 5 and the outer tube 1 Water inlet holes 3 are evenly spaced on the outer peripheral surface of the cylindrical sealed bag 2 between the inner peripheral walls. After the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com