Signal testing device of capacitive screen

A signal test and signal tester technology, used in measuring devices, parts of electrical measuring instruments, measuring electricity, etc., can solve problems such as knotting of test wires, and achieve the effect of avoiding automatic falling off and improving test efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

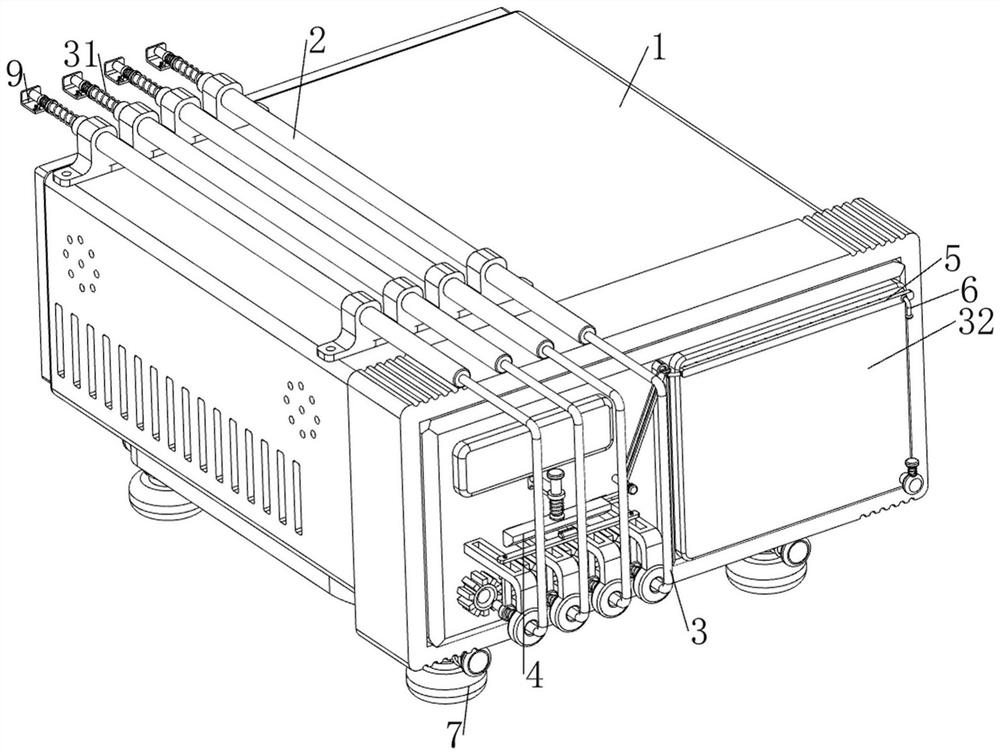

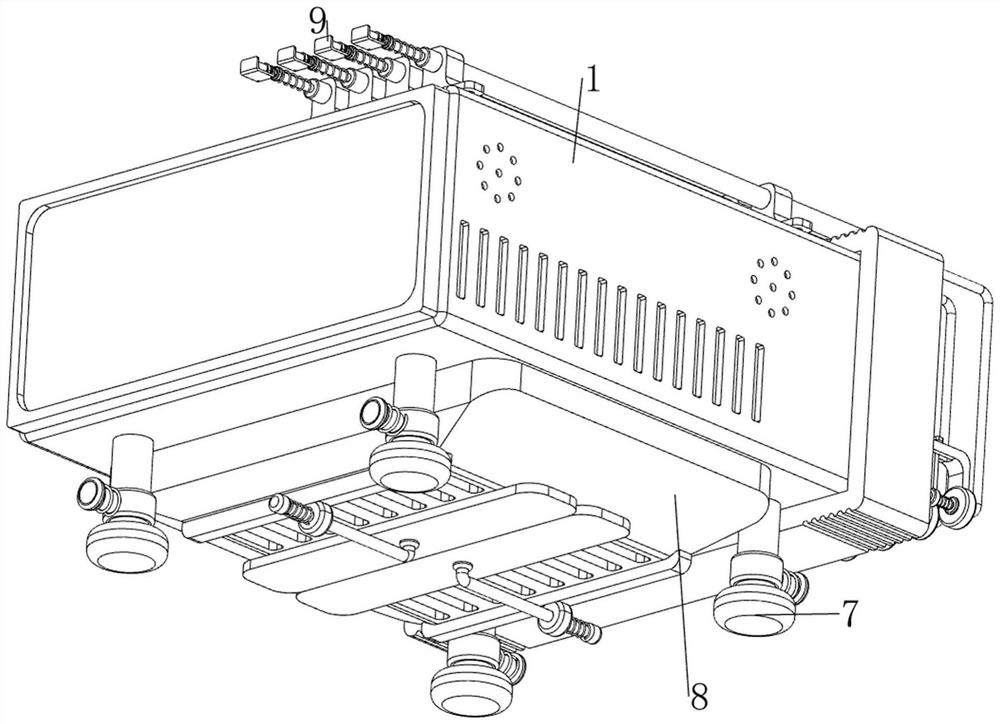

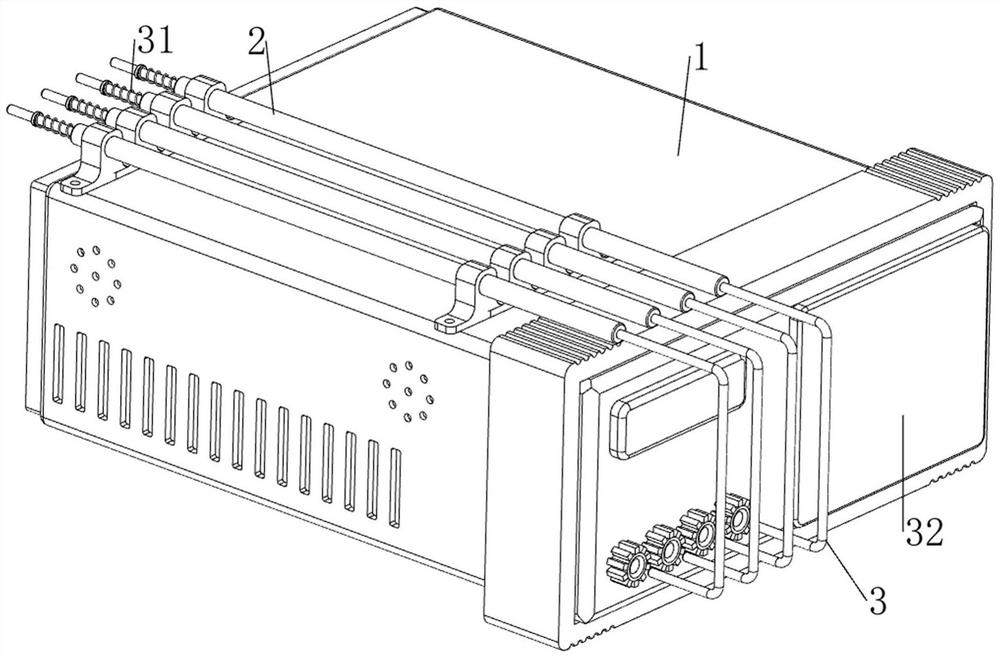

[0033] A signal testing device for a capacitive screen, such as Figure 1-3 As shown, it includes signal tester 1, guide rail 2, test line 3, first spring 31, display screen 32, wiring mechanism 4 and wiping mechanism 5. There are four guide rails 2 on the left side of the top of the instrument 1 through bolts. The test lines 3 are slidingly connected to the guide rails 2. The test lines 3 can slide back and forth in the guide rails 2. Both are provided with a first spring 31, under the action of the first spring 31, the test line 3 can be driven to move and reset, and the right front side of the signal tester 1 is provided with a display screen 32 through a bolt, and the display screen 32 is used to display the data of the signal test, A wiring mechanism 4 is provided between the left front side of the signal tester 1 and the test line 3 to facilitate the insertion of the test line 3 into the docking port of the signal tester 1, and a wiping mechanism 5 is provided on the rig...

Embodiment 2

[0038] On the basis of Example 1, such as figure 1 and Figure 8 Shown, also comprise start-up mechanism 6, start-up mechanism 6 comprises fixed rod 61, master switch 62, the 5th spring 63 and pressure bar 64, display screen 32 lower right front side is provided with fixed rod 61, slides on fixed rod 61 There is a main switch 62 connected in the same way, and a fifth spring 63 is arranged between the lower part of the main switch 62 and the fixed rod 61. Under the action of the fifth spring 63, the main switch 62 can be driven to move and reset, and the right front side of the cleaning brush 51 is welded with a pressure The rod 64 and the cleaning brush 51 move up and down to drive the pressure rod 64 to move up and down, and the pressure rod 64 can press the main switch 62 .

[0039] The downward movement of the cleaning brush 51 drives the pressing rod 64 to move downward. When the pressing rod 64 is in contact with the main switch 62, the main switch 62 can be moved downwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com