Vehicle structure with reinforced side rail

A technology for longitudinal beams and motor vehicles, applied in the directions of superstructure, substructure, vehicle components, etc., can solve problems such as unsatisfactory transmission, and achieve the effect of weakened force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

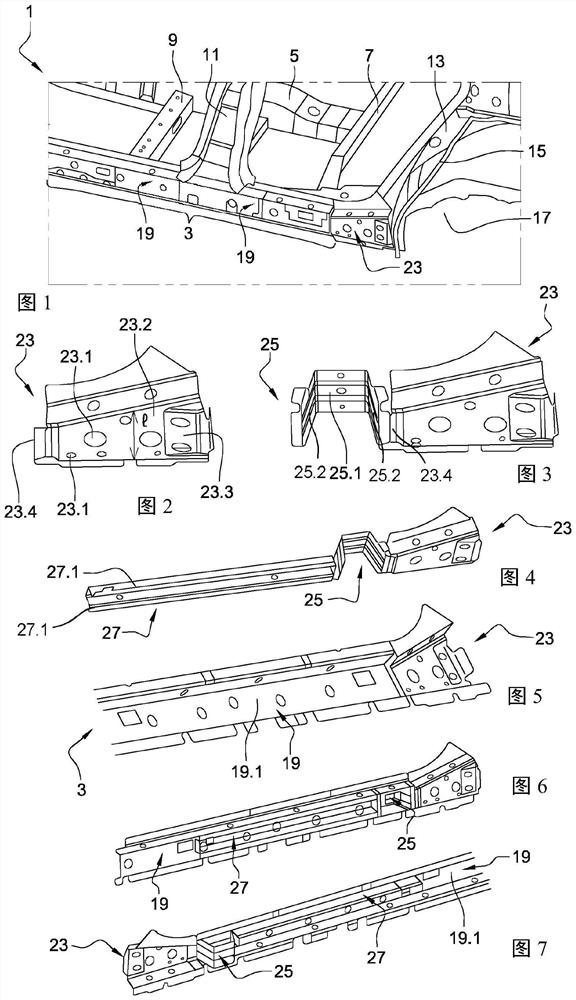

[0023] figure 1 is a partial perspective view of the underbody of a structure 1 of a motor vehicle showing side rails 3 and force transmission profiles according to the invention. In this case, the side member 3 is the side member on the left side of the vehicle, which is connected to the central duct 5 of the floor via the rear cross member 7 and the center cross member 9 and to the other parts of the structure 1 of the body via the center pillar 11 and the rear pillar 13 . Here, the rear pillars 13 together with the rear fenders 15 define wheel arch inner panels 17 of the rear wheels (not shown). The longitudinal members 3 of this underbody are generally formed by two profiles, wherein the outer profile 19 is arranged on the outside of the floor, and the inner profile is oriented on the side of the floor facing the outer profile 19 and thus in the figure 1 is not visible in . The two profiles each have a generally U-shaped section extending from the rear pillar 13 to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com