Optimal design method of conjugate heat transfer radiator with variable cross-section runner

An optimized design and radiator technology, applied in design optimization/simulation, computer-aided design, instrumentation, etc., to achieve the effect of reducing design variables, reliable temperature distribution, and beneficial to engineering practice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

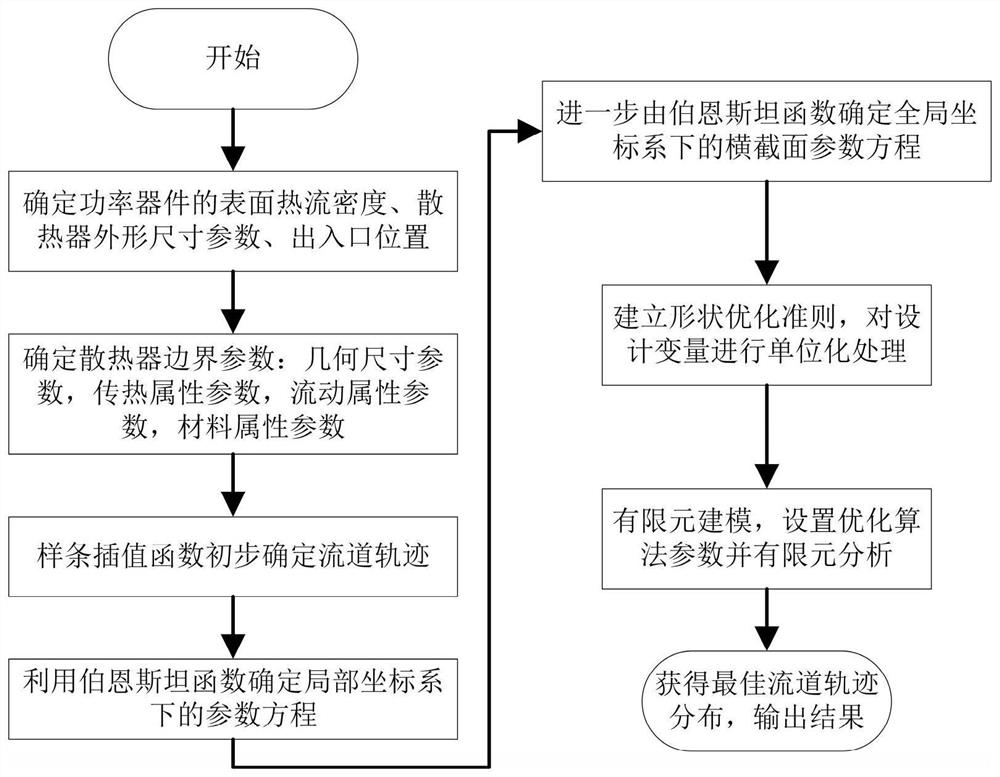

[0041] Reference attached figure 1 As shown, for an optimal design method of conjugate heat transfer radiator with variable cross-section flow channel, the specific steps are as follows:

[0042] ·Step 1, determine the surface heat flux density of the power device, the overall size of the radiator and the position of the inlet and outlet of the flow channel

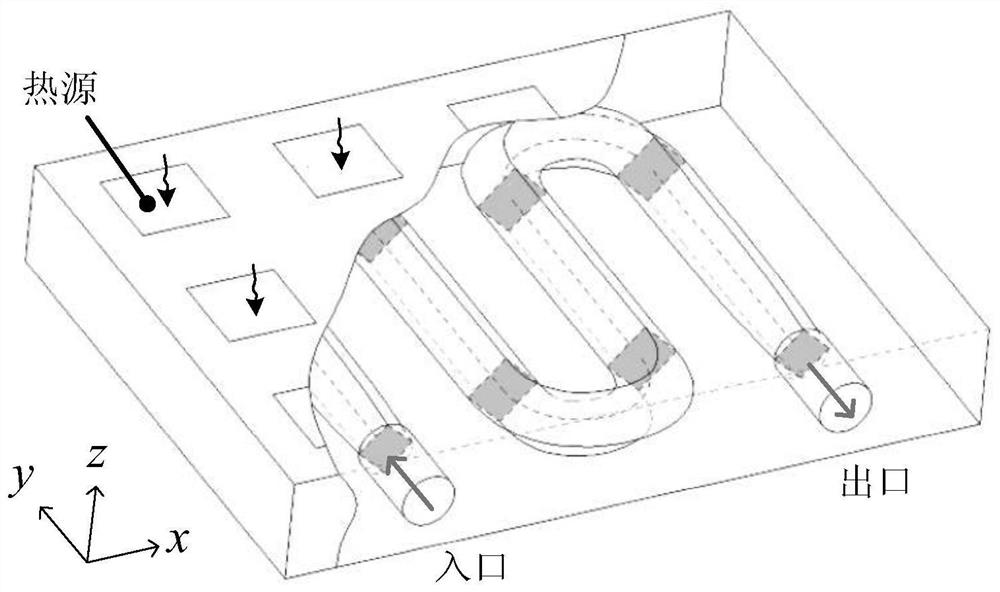

[0043] Determine the surface heat flux Q of power devices according to the configuration of on-site electronic equipment real ;Dimension parameters of the radiator: length L, width W, height H; the position of the entrance and exit, such as figure 2 shown.

[0044] · Step 2, determine the radiator boundary parameters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com