Steel plate lifting feeding bending device

A technology of lifting feeding and bending devices, which is applied in the field of mechanical processing, can solve the problems affecting the use of steel plates, bending size changes, and bending position deviations, etc., to achieve safety and stability of the device, ensure stability, and ensure processing The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

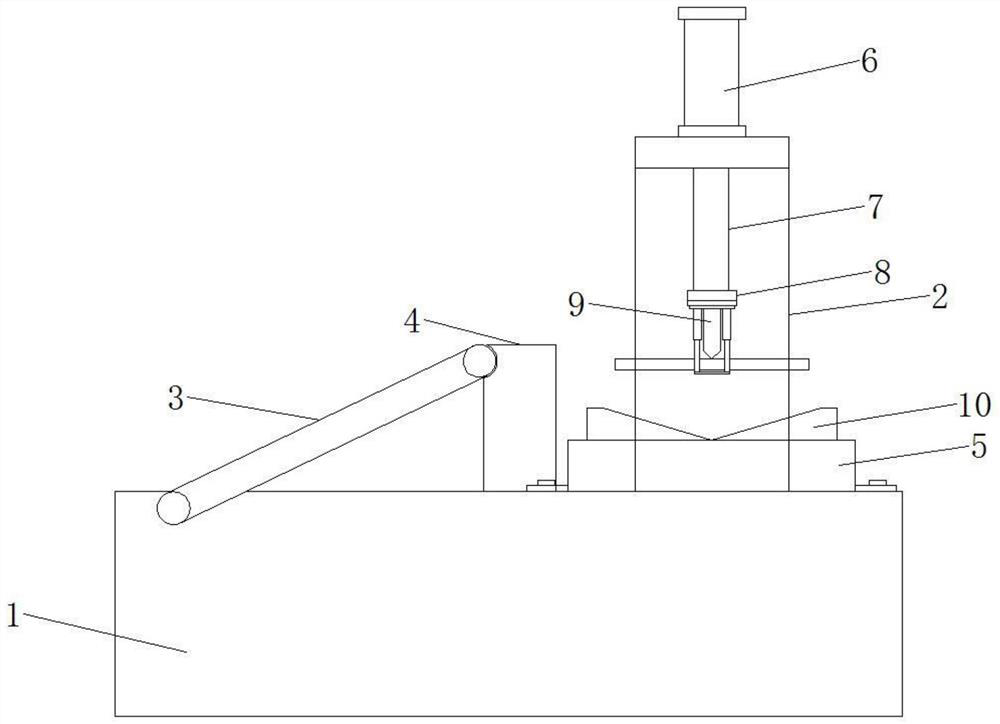

[0021] Please refer to the figure, in the embodiment of the present invention, a bending device for lifting and feeding steel plates includes a base 1, a bracket 2, a hydraulic cylinder 6, a lifting column 7, a lifting seat 8, a bending pressure head 9 and a bending model 10 The support 2 is fixedly installed on the base 1, the support 2 is a gantry structure, and the upper surface of the corresponding base 1 in the support 2 is fixedly installed with a mounting seat 5, and the mounting seat 5 is fixed on the base 1 by bolts, which is convenient for the mounting seat 5 Disassembly, a bending model 10 is fixed on the mounting base 5, and the steel plate is bent on the bending model 10; a vertical hydraulic cylinder 6 is fixedly arranged on the top of the support 2, and the output shaft of the hydraulic cylinder 6 is vertical Downward, the lower end of the output shaft of the hydraulic cylinder 6 is coaxially fixedly connected with a lifting column 7, and the lifting column 7 is ...

Embodiment 2

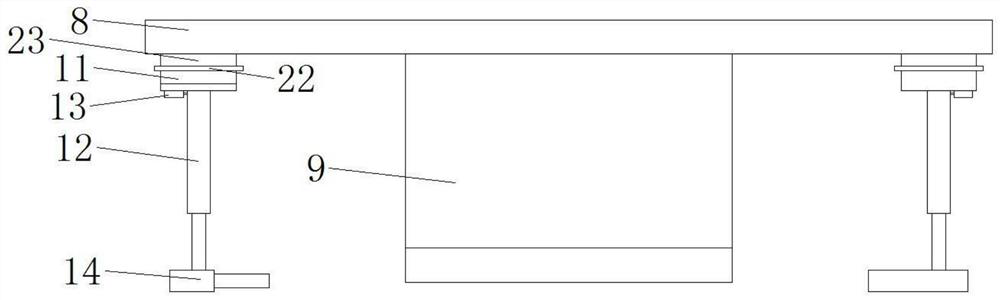

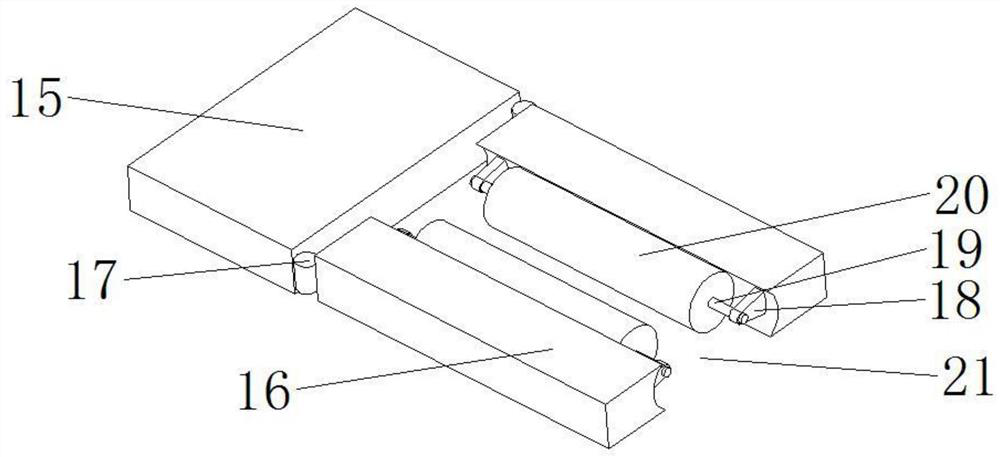

[0025] On the basis of Embodiment 1, a sliding connection can be used between the mounting block 11 and the lifting seat 8, specifically, a sliding seat 23 is provided between the mounting block 11 and the lifting seat 8, and the sliding seat 23 is slidably connected to the lifting seat 8. The lower surface of the seat 8 makes the sliding seat 23 move in the horizontal direction, adjusts the distance with the bending head 9, and adjusts the distance through the steel plate support structures 14 at both ends, so as to adapt to the bending of steel plates of different lengths; the sliding seat 23 It is rotationally connected with the mounting block 11 through a horizontal rotating shaft 22, and the rotating shaft 22 is parallel to the support shaft 19, so that the mounting block 11 swings back and forth around the rotating shaft 22, so that the horizontally pushed steel plate enters between the two steel plate support structures 14 Installation between the steel plate support str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com