A prefabricated building wall truss structure

A technology for building walls and prefabrication, applied in truss-type structures, building components, building structures, etc., can solve problems such as incompatibility with on-site installation conditions, truss cannot be adjusted in width, etc., and achieves strong practicability and good stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention will be described in detail below.

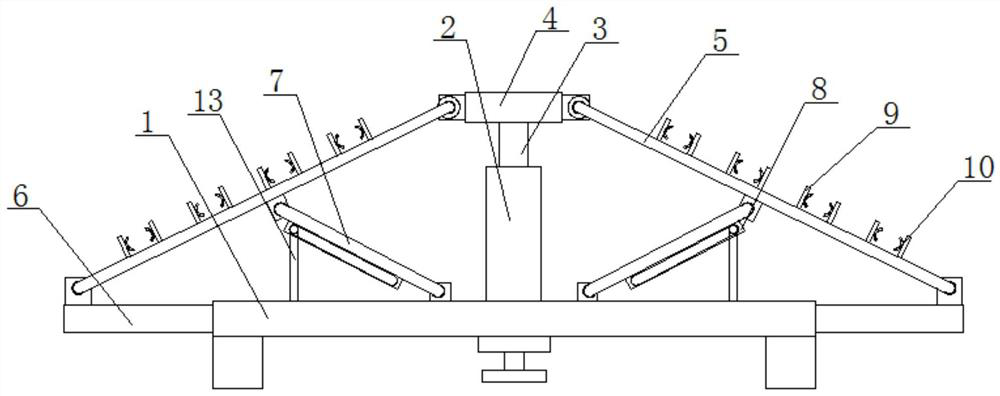

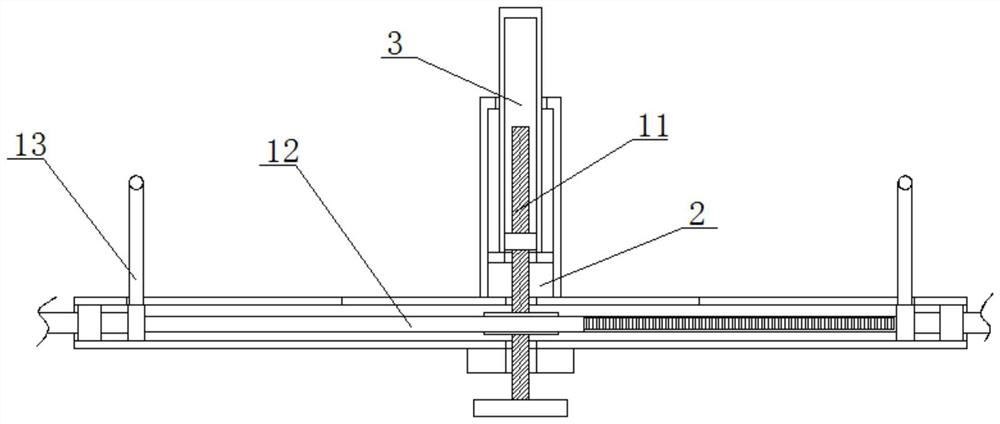

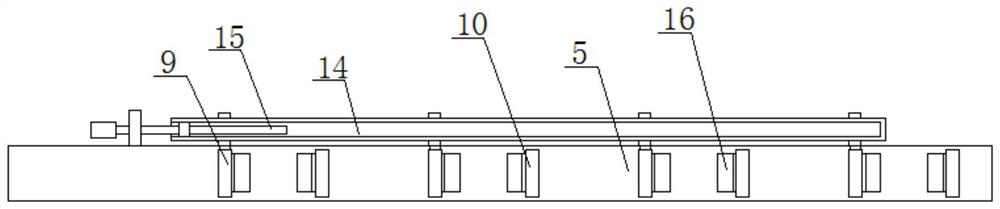

[0028] The reference signs in the accompanying drawings of the specification include: 1. Support pipe, 2. Limiting cover, 3. Lifting cover, 4. Connecting pipe, 5. Support beam, 6. Moving column, 7. Support rod, 8. Transmission ring, 9. Moving splint, 10. Fixed splint , 11 transmission screw, 12 transmission rack, 13 connecting rod, 14 thread cover, 15 locking screw, 16 hoop, 17 transmission gear, 18 thread column, 19 thread plate, 20 limit ring, 21 moving rod, 22 Turn bar, 23 limit plates, 24 slide rails, 25 slide plates, 26 fixed gears, 27 arc racks, 28 rotating shafts, 29 bevel gears.

[0029] like Figure 1-6 A prefabricated building wall truss structure shown includes a support tube 1, a support cover 2 is fixedly installed on the top of the support tube 1, and a lift cover 3 is slidably connected to the support cover 2, and the top of the lift cover 3 extends to The top of the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com