A glue device for processing small bamboo and wood furniture that can fit accurately

A small furniture, laminating technology, applied in wood processing appliances, adhesive application devices, manufacturing tools, etc., can solve the problems of glue overflow, poor spatial viewing angle, inability to accurately combine at one time, avoid damage, improve gluing efficiency, Improve the effect of pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

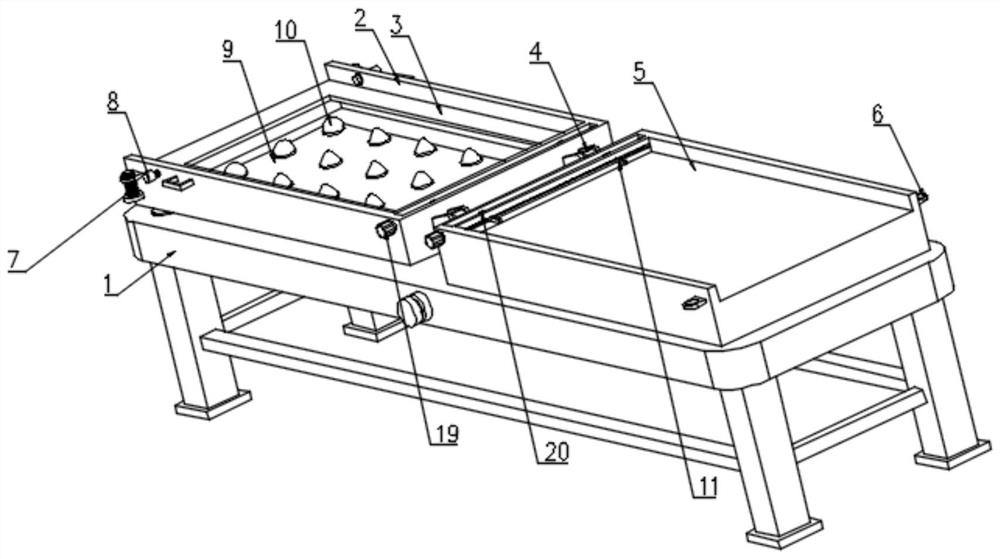

[0037] see Figure 1-5 , a glue device for processing small bamboo and wood furniture that can fit accurately, including a workbench 1, and the glue device also includes:

[0038] The movable seat 2 is connected with the fixed seat 5, the bottom of the fixed seat 5 is fixedly connected with the top of the workbench 1, and the movable seat 2 and the outer wall of the vertical end of the fixed seat 5 are connected by rotation through the rotating member 4, and the movable seat 2 and the fixed seat 5 are longitudinally connected. The inner surface wall of the end is provided with a bidirectional threaded rod 19, and the outer wall of the bidirectional threaded rod 19 is screwed and connected with two sets of threaded sleeves 20 through two sets of opposite thread grooves, and the outer walls of the two sets of threaded sleeves 20 are fixedly installed with movable settings. The clamping block 11, the inner surface wall of the movable seat 2 is fixedly installed with a support fra...

Embodiment 2

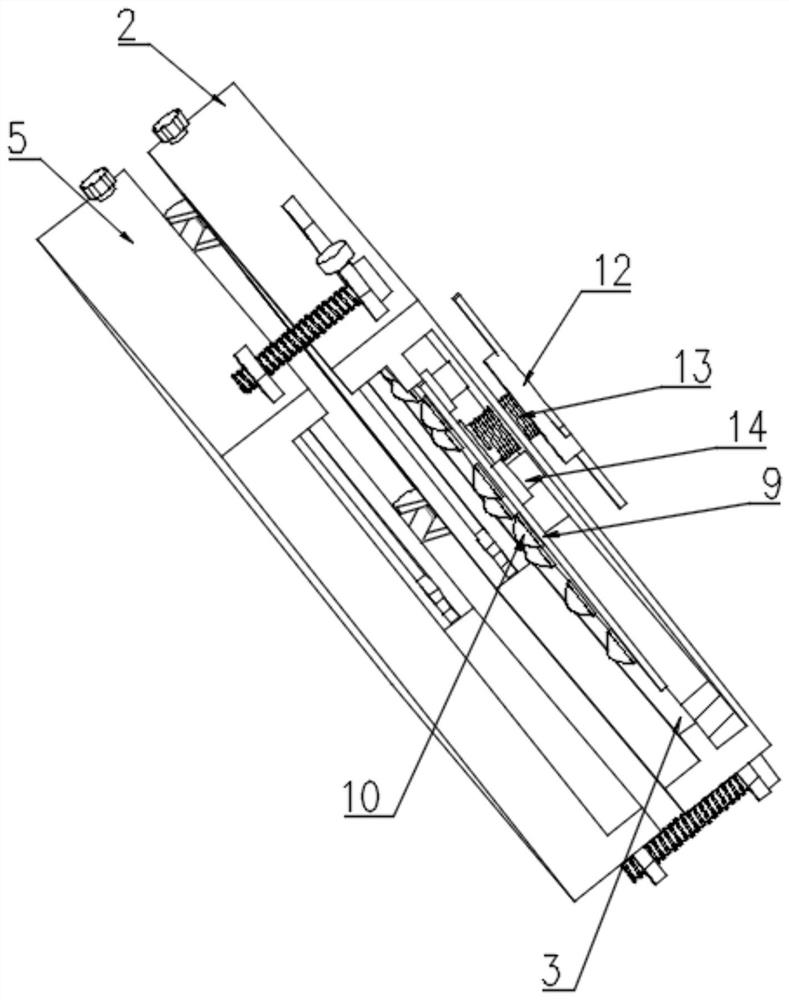

[0043] see figure 2 and image 3 , the bottom of the movable seat 2 is screwed and connected with a transmission rod 13, and the open end of the transmission rod 13 is fixedly connected with a rotary handle 12, and the side of the transmission rod 13 away from the rotary handle 12 is snapped and connected with a push plate 9, and the top of the push plate 9 is fixedly installed There is an elastic block 10 , and a telescopic rod 14 fixedly connected to the inner surface wall of the movable seat 2 is fixedly installed on the side of the push plate 9 close to the transmission rod 13 , so as to limit the axial rotation of the push plate 9 .

[0044] After the screw 7 realizes the fixing of the movable seat 2 and the fixed seat 5, the rotary handle 12 can be rotated at this time, the transmission rod 13 is screwed with the inner surface of the movable seat 2, and the bottom is relatively movable with the push plate 9, and the push plate 9 moves downward. Pushing the elastic bloc...

Embodiment 3

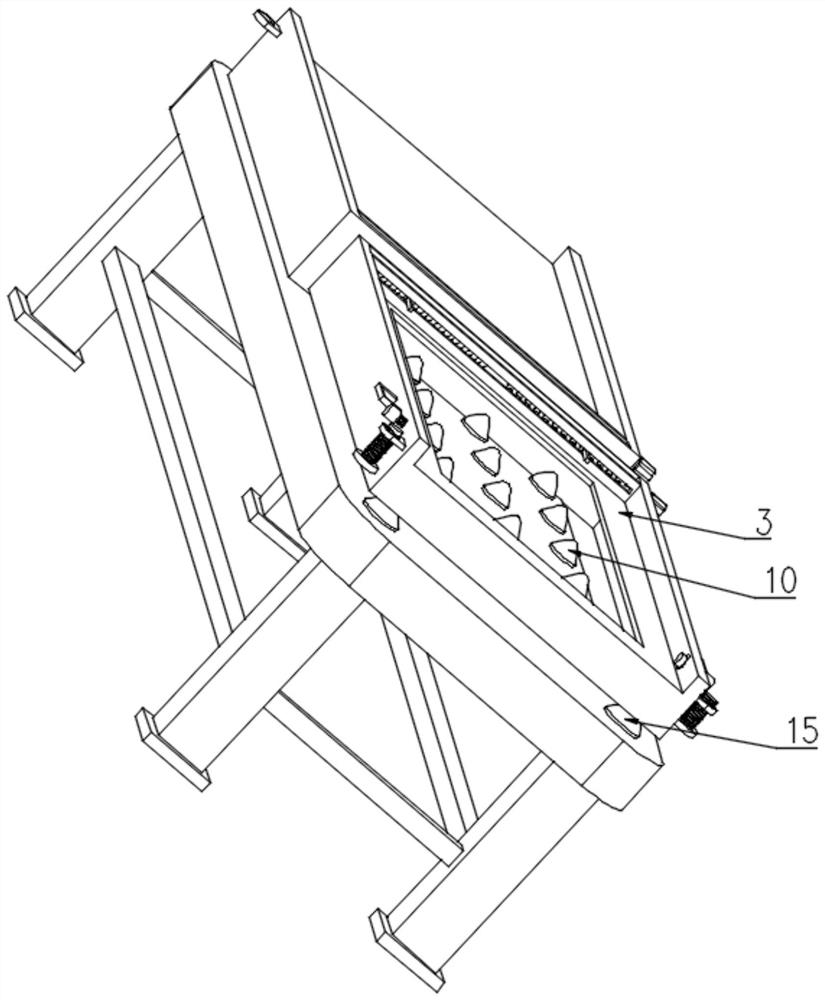

[0047] see figure 1 and Figure 5The outer wall of the longitudinal end of the workbench 1 is fixedly installed with a combination seat 18, and the inner surface wall of the combination seat 18 is screwed and connected with a rotary seat 16.

[0048] After completing the positioning of plate 1 and plate 2, rotate the rotary seat 16 to make it screw with the inner surface of the combination seat 18 until the rotary seat 16 drives the cleaning block 17 to disengage the combination seat 18. At this time, the rotary seat 16 can be manually held and used. The cleaning block 17 cleans the joint surface of the first plate and the second plate. It is only necessary to replace the cleaning block 17 periodically, which can ensure the continuous use of the cleaning mechanism, thereby ensuring the positional stability of the cleaning block 17 and ensuring the cleaning block 17. The instant access avoids its loss and omission, thereby improving the convenience of sheet gluing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com