Concrete test block curing spacing isolation device and using method thereof

The technology of a concrete test block and an isolation device is applied in the preparation of test samples, ceramic molding machines, manufacturing tools, etc., and can solve the problems of less personnel configuration, close contact between surfaces, disordered placement, and high labor intensity. Achieve the effect of avoiding tight fit, convenient placement of test blocks, and avoiding stacking confusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

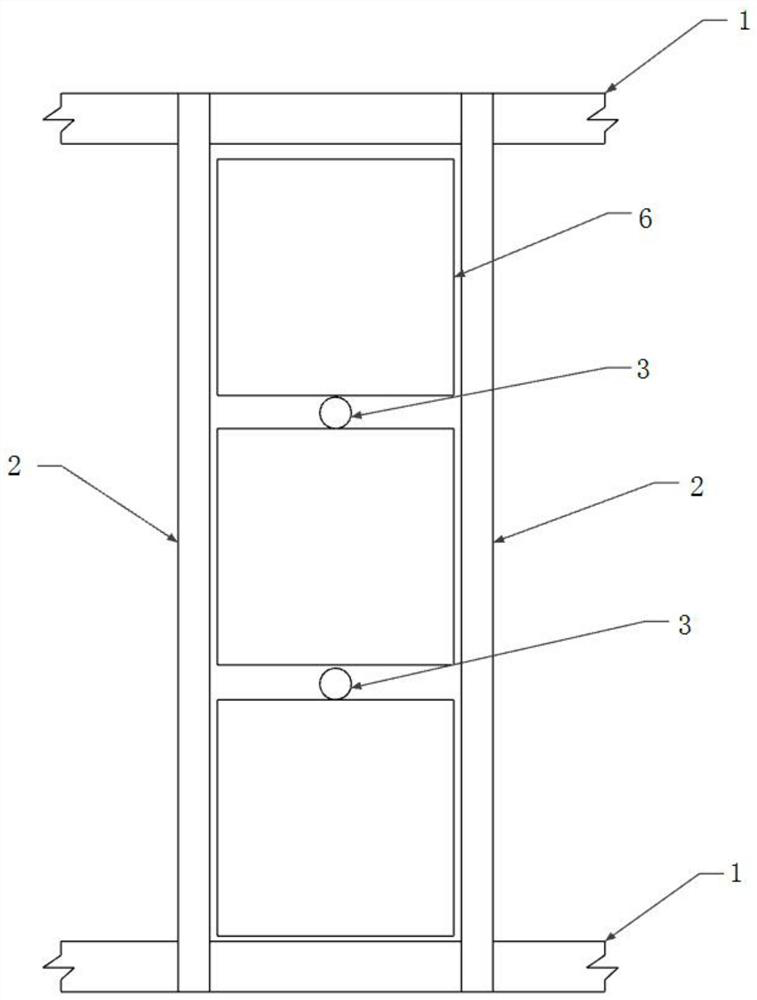

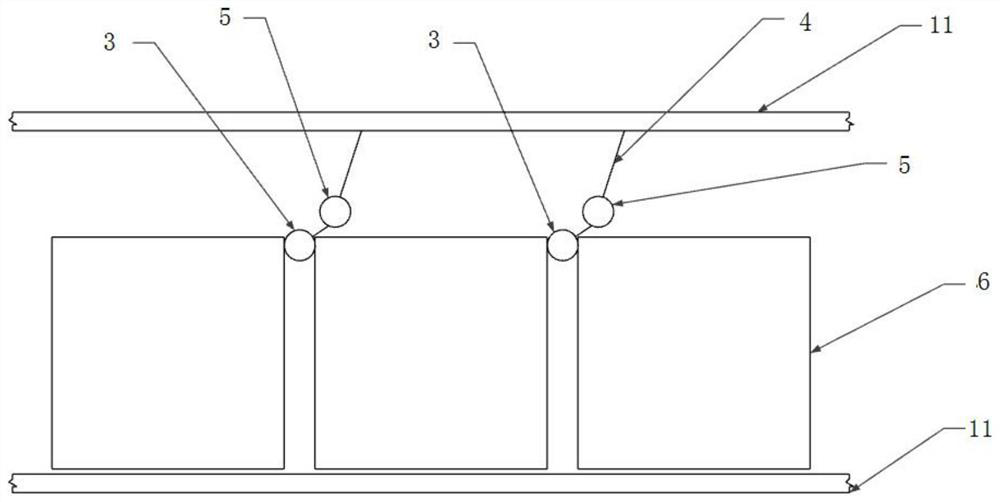

[0013] refer to figure 1 , the present embodiment provides a concrete test block curing spacing isolation device, including a curing frame 1, the curing frame 1 includes at least two sample curing plates 11 distributed vertically, the sample curing plates 11 are arranged horizontally, and the sample curing The upper end of the plate 11 has two longitudinal spacer strips 2 arranged in parallel, the distance between the two longitudinal spacer strips 2 is greater than the width of the test piece 6 by 2 cm, and the space between the two longitudinal spacer strips 2 is arranged in sequence The test piece is placed in the area, and the isolation ball 3 is suspended by the sling 4 between two adjacent test piece placement positions, and the distance between the isolation ball 3 and the sample maintenance plate 11 below is less than the height of the test piece 6 , the top of the suspension rope 4 is fixed on the sample maintenance plate 11 above.

[0014] Each layer of the curing f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com