A kind of gunpowder gas cooling device

A technology for cooling devices and gas, which is applied in the direction of household refrigeration devices, separation methods, lighting and heating equipment, etc. It can solve the problems of low cost performance, low cooling effect of cooling components, and inability of gas generators to meet actual use requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

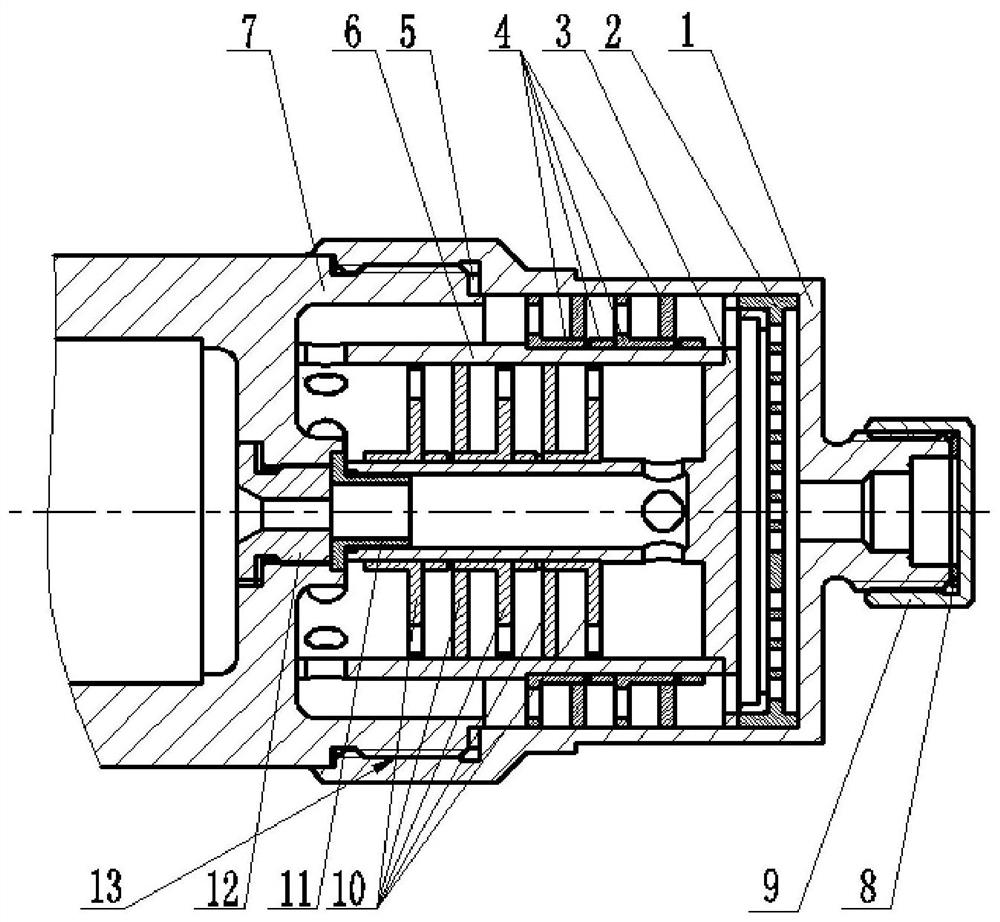

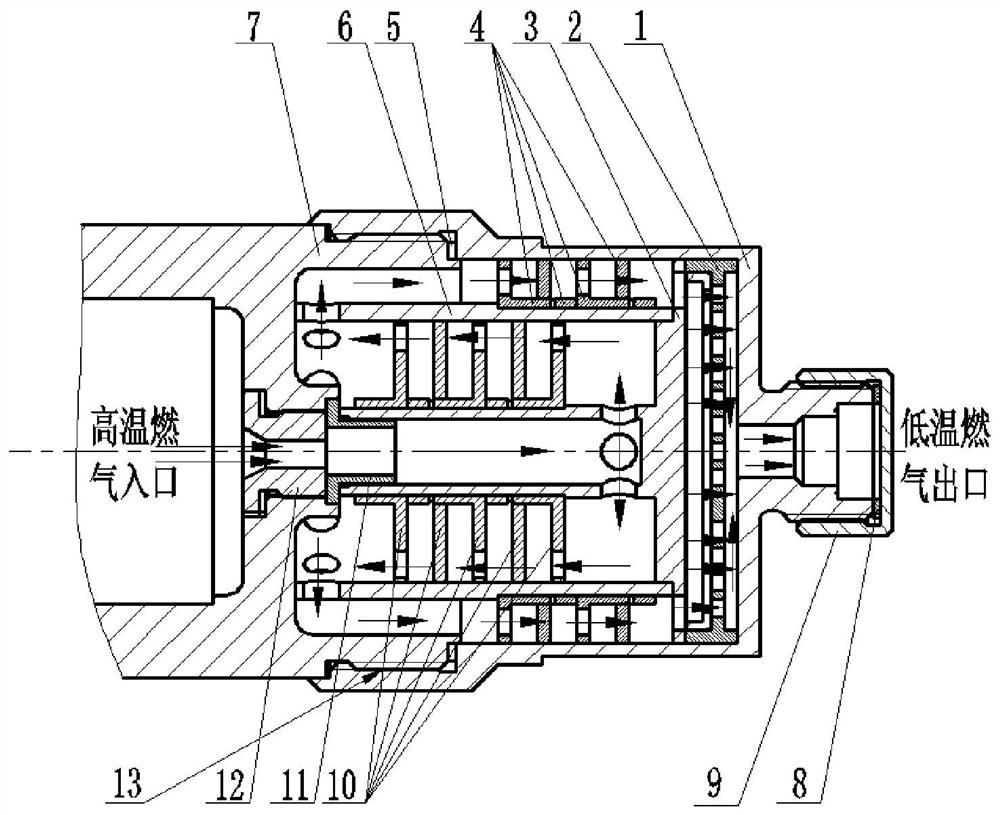

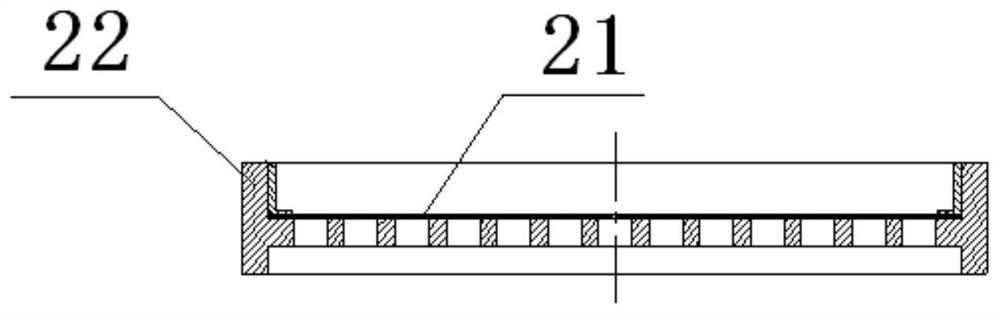

[0051] like figure 1 As shown, a propellant gas cooling device of the present invention includes: a blocking plate 11 , a primary cooling component, a secondary cooling component and a filter plate assembly 2 . The primary cooling component and the secondary cooling component divide the cooling device into multi-layer cavities radially from the inside to the outside, figure 2 As shown, the high-temperature gas is sprayed into the innermost cavity through the blocking plate 11, flows through the cavities of each layer in sequence from the inside to the outside, and then flows out through the filter plate assembly 2.

[0052] The flow direction of the high-temperature gas in the chambers of two adjacent layers is opposite; at the same time, the chamber is provided with multi-layer partitions arrayed along the axial direction, and thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com