Hand-pressing type socket wrench

A socket wrench, hand pressure technology, applied in the wrench field, can solve the problem of inconvenient ratchet wrench, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described in detail by describing the embodiments below with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

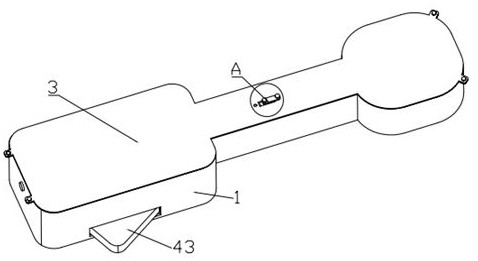

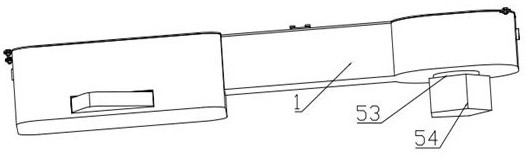

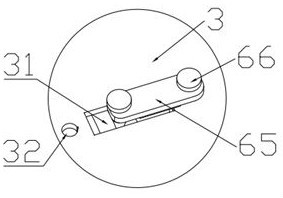

[0022] Such as Figure 1-7 As shown, the present invention provides a hand-pressed socket wrench, including a housing 1, a rotating shaft 2, a cover body 3, a hand-pressed driving mechanism 4, a socket driving mechanism 5 and a steering conversion mechanism 6;

[0023] The two ends of the rotating shaft 1 are slidably inserted into the shaft holes at the front and rear ends of the housing 1, and the cover 3 is fixed on the top of the housing 1;

[0024] The manual driving mechanism 4 is arranged at the rear end of the housing 1 and is used to drive the sleeve driving mechanism 5 to rotate by manual pressing;

[0025] The sleeve drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com