Gasoline chain saw with display function and information display method

A display function and information display technology, applied in the direction of chain saws, sawing components, manufacturing tools, etc., can solve problems such as maintenance of chain saws, hidden safety hazards, normal use and life risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

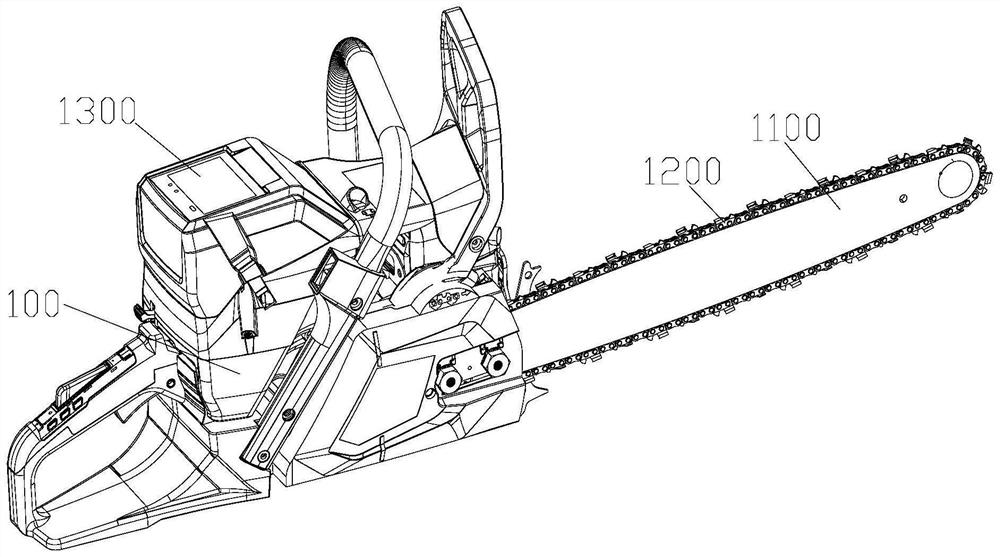

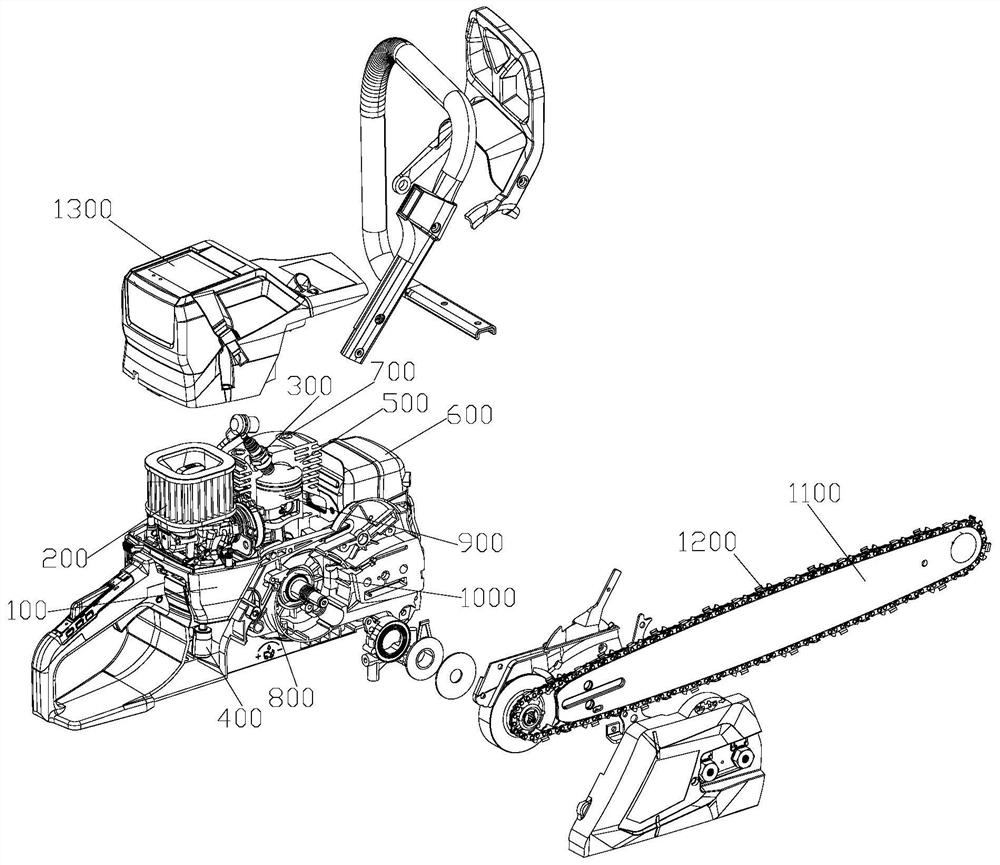

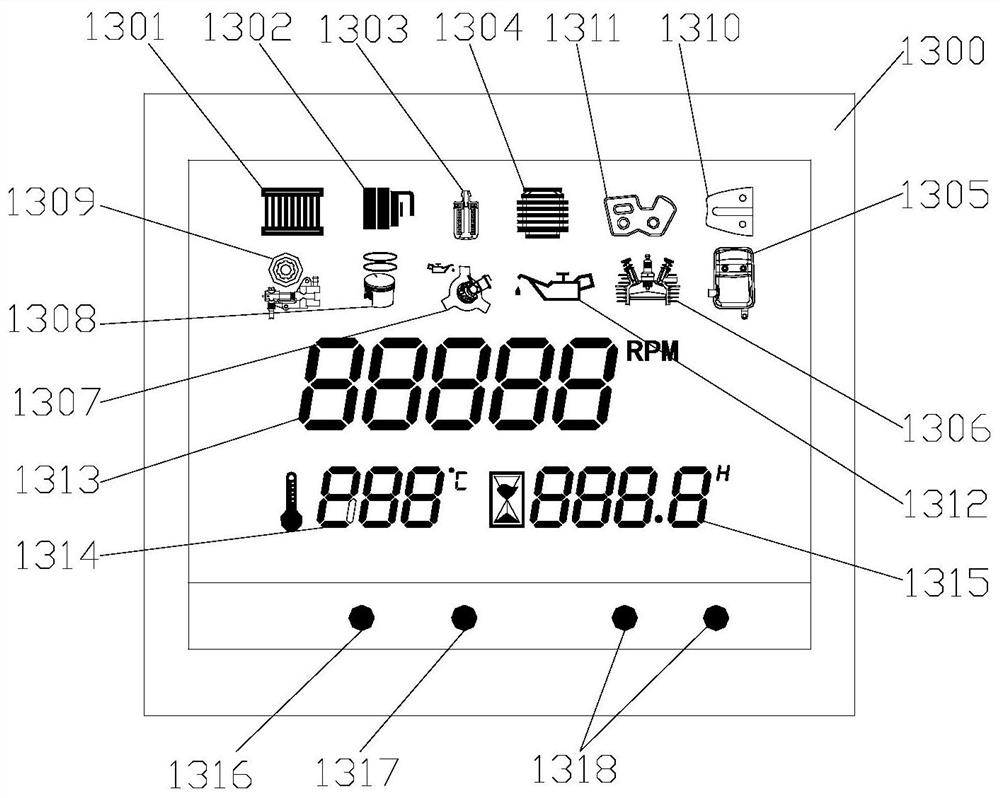

[0056] Such as figure 1 and figure 2 A gasoline chain saw with a display function is shown, which includes a housing 100, and the interior of the housing is respectively equipped with an air filter 200, a spark plug 300, a fuel filter 400, a cylinder 500, a muffler 600, a valve 700, a gear box 800, and a piston 900 and oil pump 1000, the spark plug is provided with a rotational speed sensor, and the cylinder is provided with a first temperature sensor; a guide plate 1100 is provided on the housing, a second temperature sensor is provided on the guide plate, and a saw chain 1200 is provided for rotation on the guide plate; There are such as image 3 As shown in the control panel 1300, the control panel is equipped with a rotational speed signal collector, a working time timer and an abnormal time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com