Wall penetrating device assisting in integrally forming sleeve and wall penetrating method of wall penetrating device

A kind of integral molding and wall-penetrating technology, which is applied in the direction of sound-producing equipment, instruments, stone processing tools, etc., can solve problems such as loud noise, health hazards of staff, and unfavorable collection and disposal of waste materials, so as to achieve health protection and facilitate collection and disposal. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

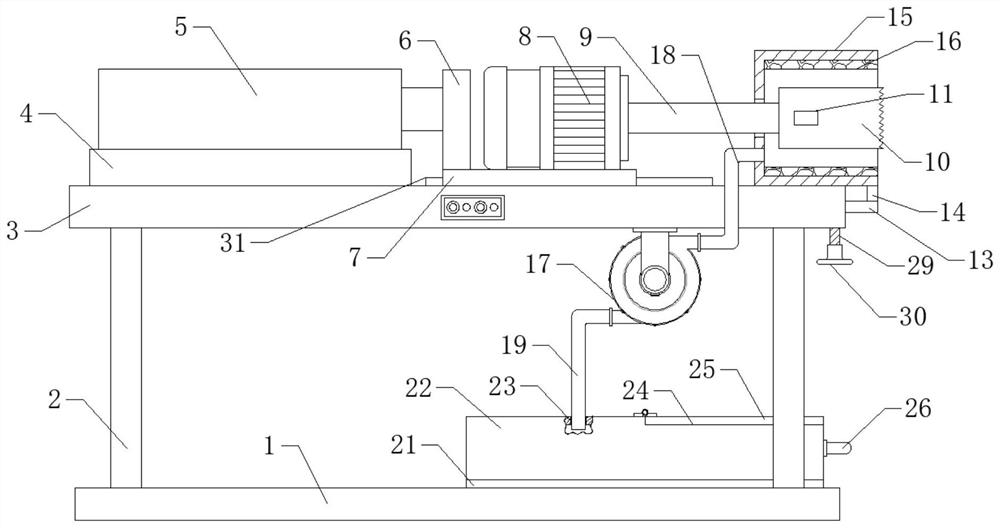

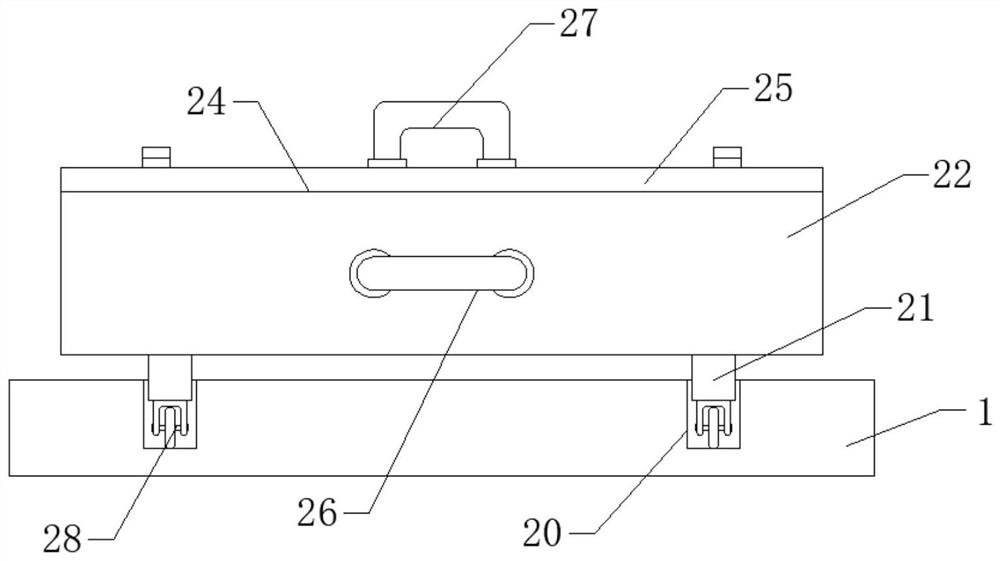

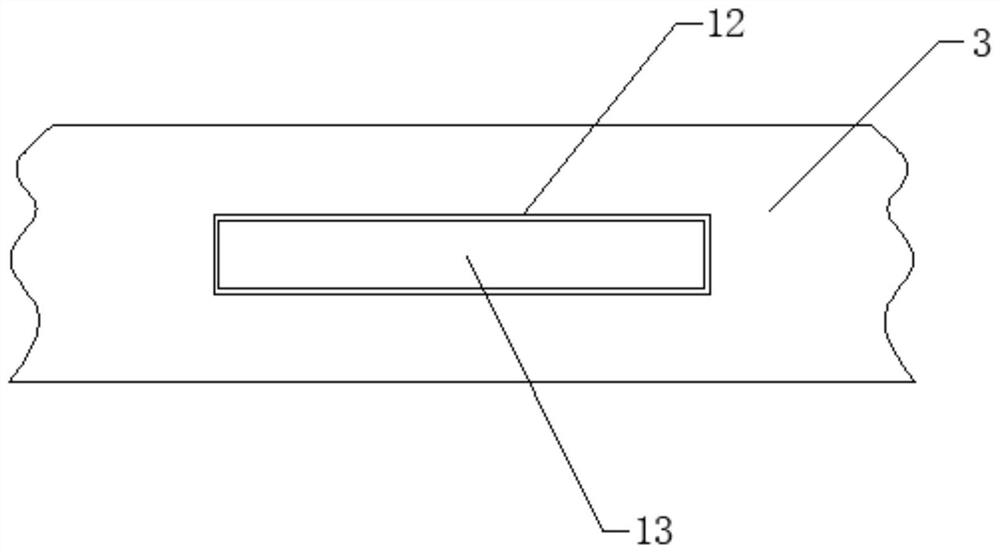

[0024] see Figure 1-4 , the present invention provides a technical solution: a wall-penetrating device for auxiliary integrally formed sleeves, including a bottom plate 1, four support plates 2 are symmetrically welded on the upper surface of the bottom plate 1, and the tops of the four support plates 2 are welded with a first Fixed plate 3, the upper surface of the first fixed plate 3 is welded with the second fixed plate 4, the upper surface of the second fixed plate 4 is equipped with a cylinder 5, the piston rod of the cylinder 5 is fixedly connected with the third fixed plate 6, the third fixed plate The bottom of the plate 6 is welded with a fourth fixed plate 7, a motor 8 is installed on the upper surface of the fourth fixed plate 7, the output end of the motor 8 is fixedly connected with a rotating shaft 9, and one end of the rotating shaft 9 is fixedly connected with a drill bit 10, the outside of the drill bit 10 The wall is provided with a chip removal hole 11, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com