Vehicle windshield wiper blade

A windshield and wiper technology, applied in vehicle maintenance, vehicle cleaning, transportation and packaging, etc., can solve problems such as reducing the efficiency of wipers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

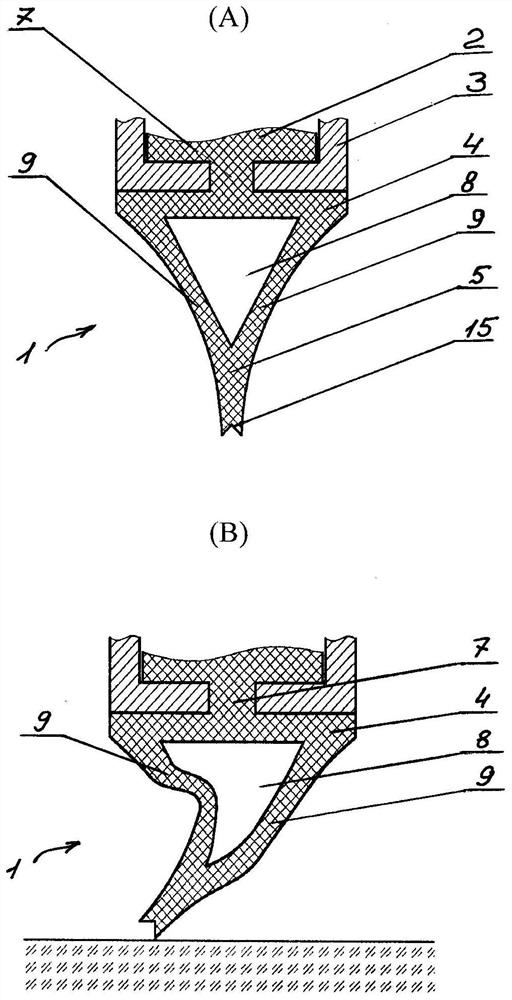

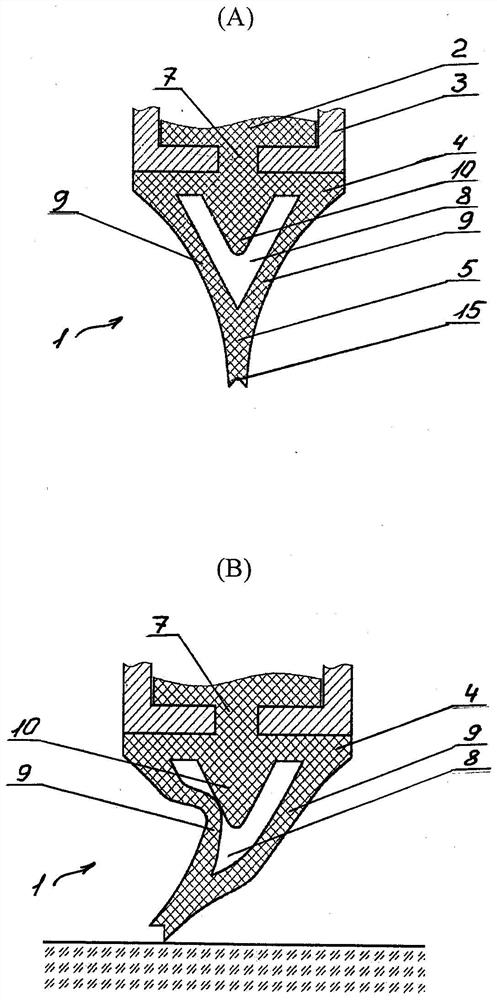

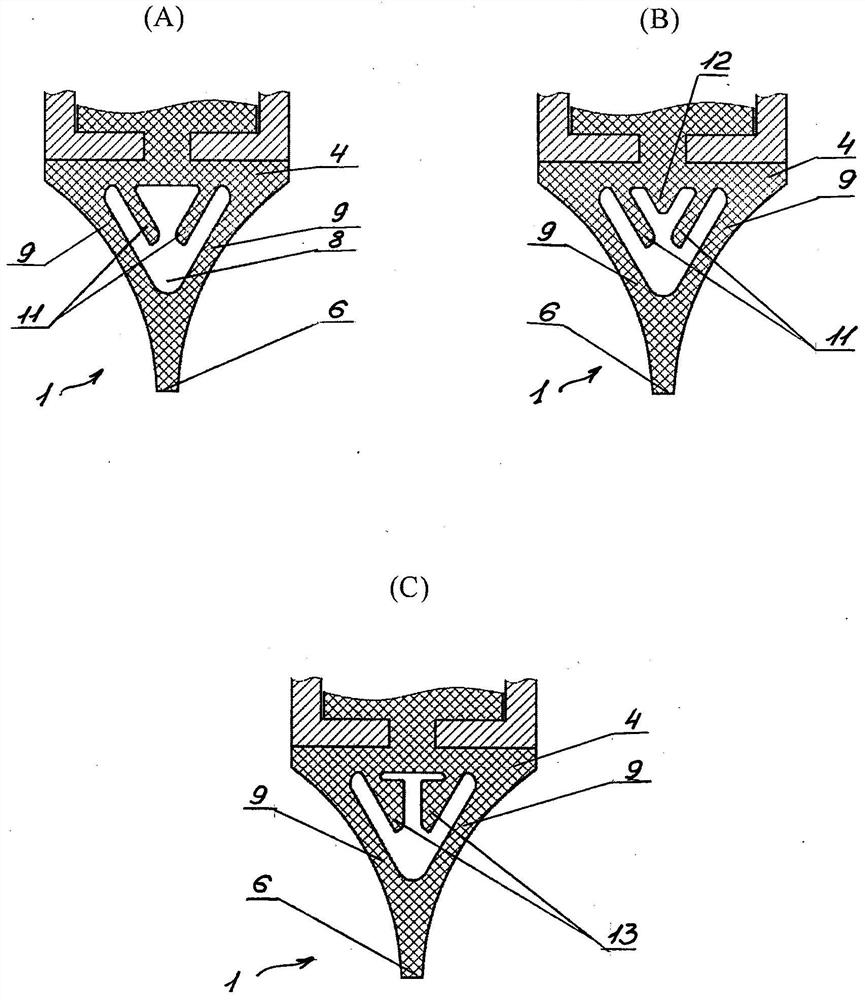

[0022] Hereinafter, suggested embodiments of the present invention are given with reference to the accompanying drawings. Stripe 1 ( figure 1 (A)) comprises a base 2 adapted to be fixed in a holder 3 and a wedge-shaped scraper 4 with a protruding contact portion 5 with a sweeping edge 6 . The scraping part 4 is connected to the base part 2 through a connection assembly 7 . The strip 1 is fitted tightly (without gaps) and fixedly in the cage 3 . The side wall 9 of the wiper 4 is formed by a triangular cavity 8 which is located in the center of the strip, centered on the axis of the strip and extending throughout the entire length of the strip above the projection of the wiper. The thickness of each side wall 9 of the wiper 4 is proportional to the thickness of the protruding portion 5 of the wiper 4 . The plug 14 can be inserted into the through cavity 8 of the rubber strip 1 . The sweeping edge 6 has an axisymmetric longitudinal notch 15 with a triangular cross-section ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com