Polyurethane sponge cutting processing device and cutting processing method thereof

A technology of polyurethane sponge and processing equipment, which is applied in metal processing and other directions, can solve problems such as difficult clamping operations, difficult sponges, and difficult guarantees, and achieve the effects of avoiding winding springback, reducing diameter, reducing workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

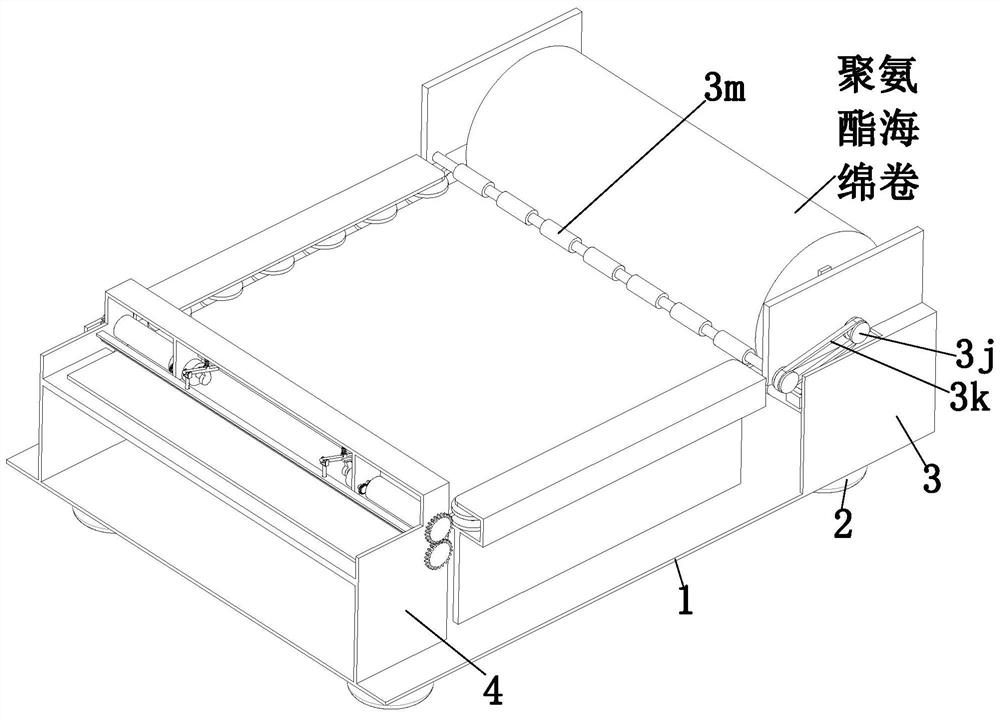

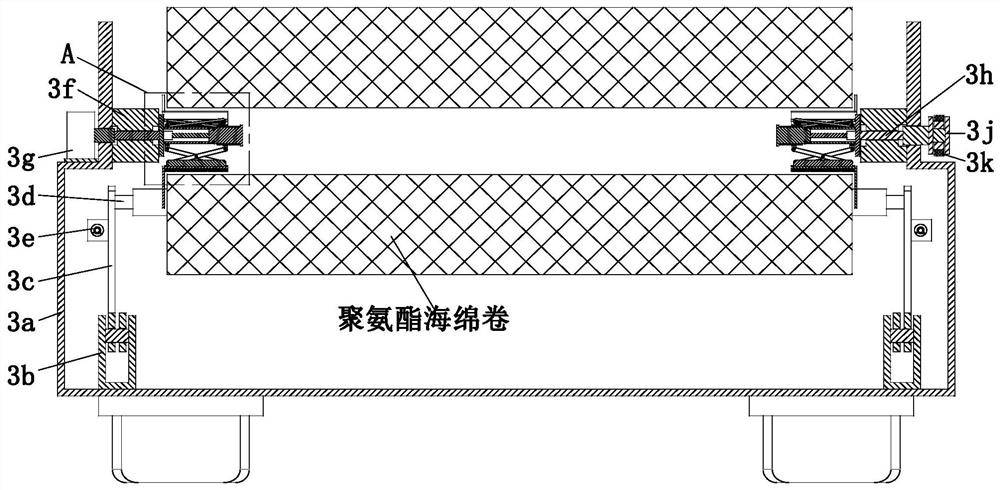

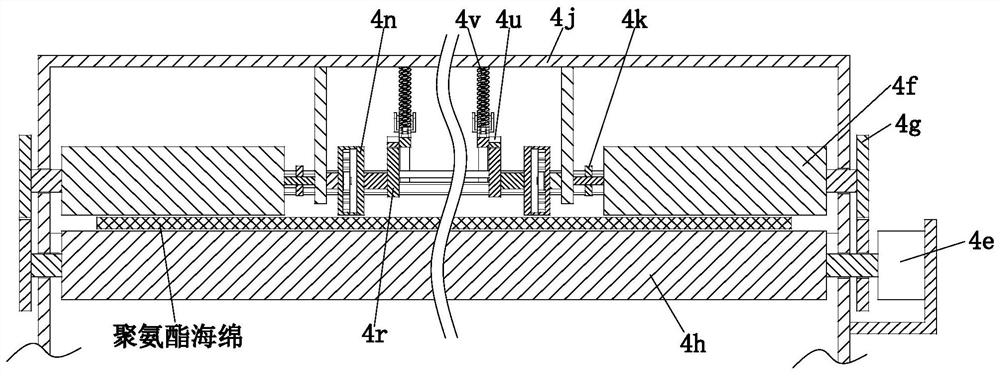

[0029] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further elaborate the present invention.

[0030] A polyurethane sponge cutting and processing equipment, comprising an installation base plate 1, a support foot 2, a conveying mechanism 3 and a cutting mechanism 4, the corners around the lower end of the installation base plate 1 are uniformly equipped with support feet 2, and the upper end of the installation base plate 1 passes through A conveying mechanism 3 is installed in rotation fit, and a cutting mechanism 4 is installed on the installation base plate 1 .

[0031] The conveying mechanism 3 includes a supporting plate 3a, a supporting frame 3b, a supporting connecting rod 3c, a supporting rotating shaft 3d, a supporting spring 3e, a conveying base 3f, a conveying motor 3g, a driving rotating shaft 3h, a synchronous wheel 3j, a synchr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com