Novel bush inner framework

A technology of inner frame and bushing, which is applied in the field of auto parts, can solve the problem of poor fastening performance of the inner frame of the bushing, and achieve the effect of avoiding slipping and loosening and improving the use strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

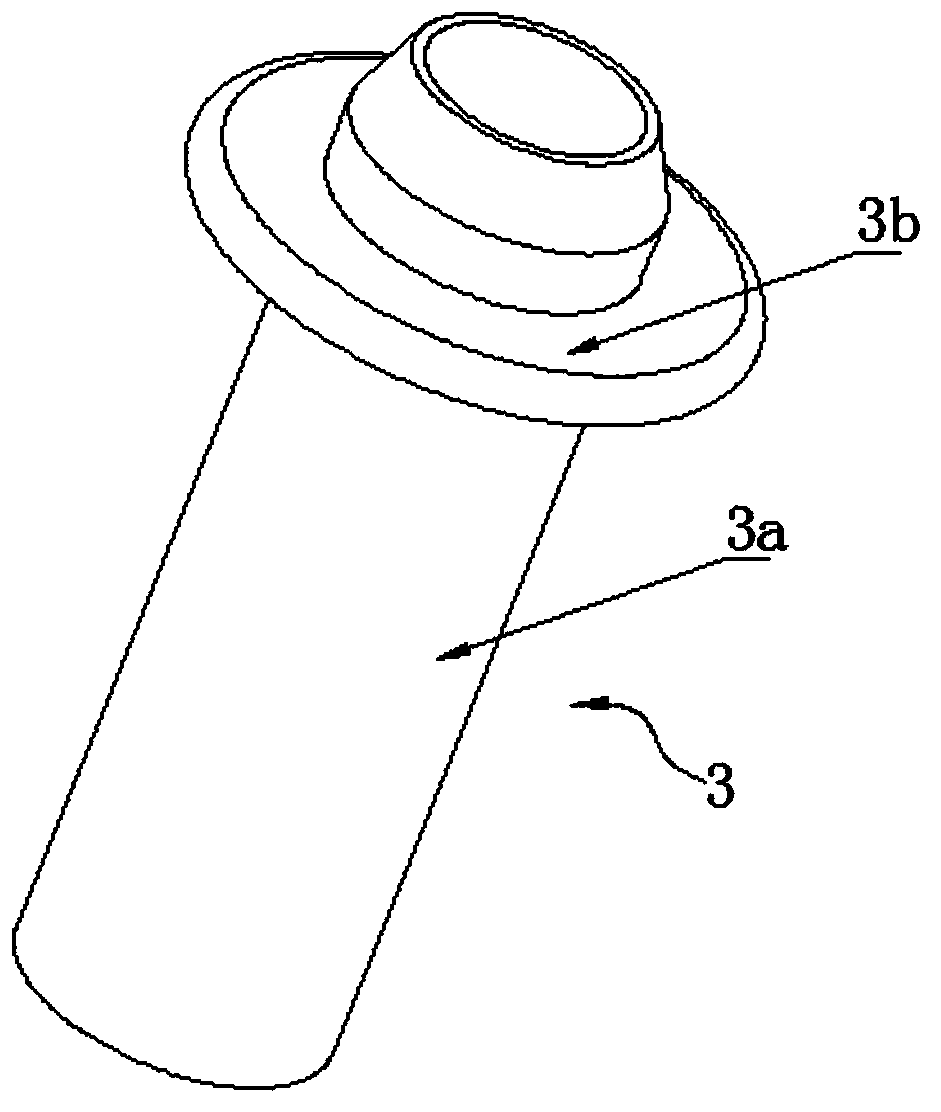

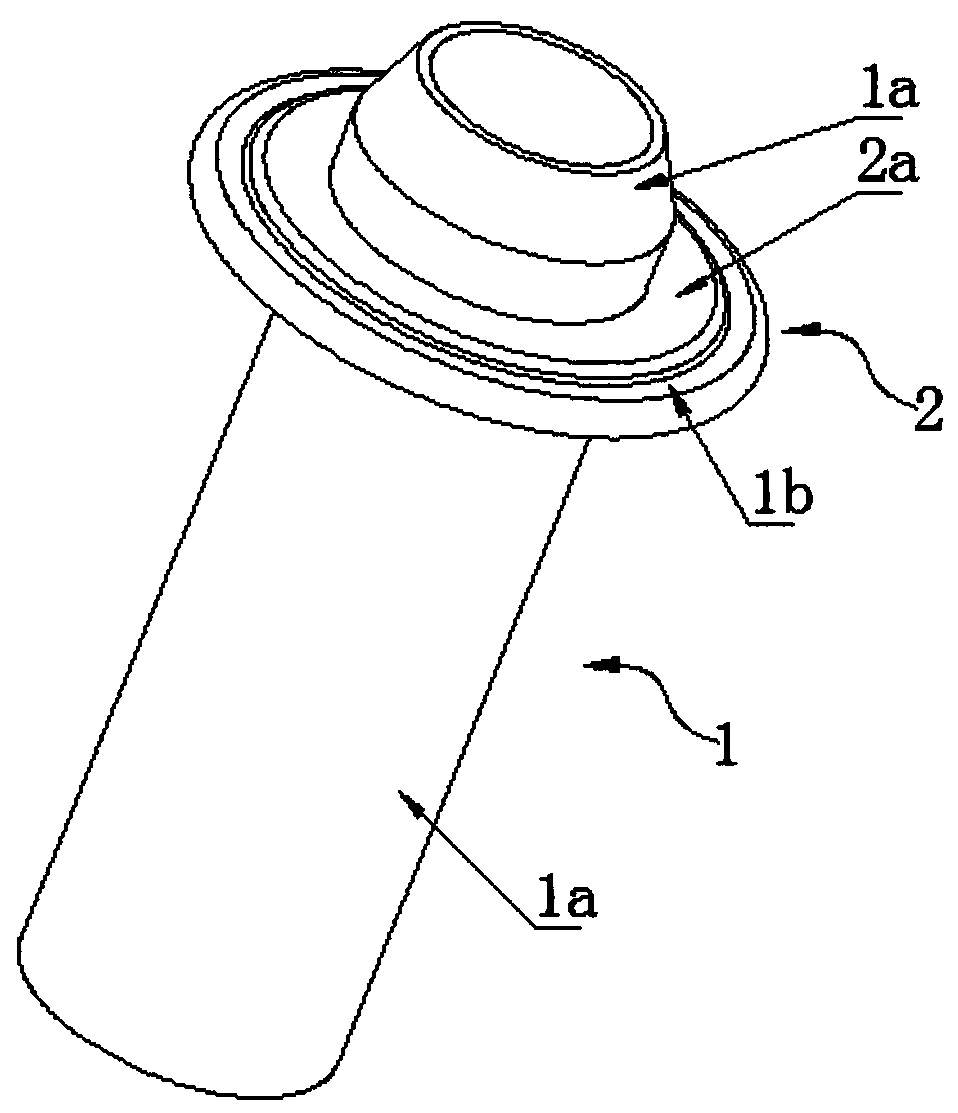

[0024] Embodiment 1 is: a new inner skeleton of the bushing, refer to image 3 with Figure 4 As shown, it includes a bushing connecting pipe 1a and a connecting flange 1b. The connecting flange 1b is provided with a fastening structure 2 integral with it. The fastening structure 2 includes a fastening pad 2a integrally provided with the flange; The solidity of the gasket 2a and the connecting flange 1b and the bushing connecting pipe 1a are uniformly arranged so as to avoid slipping and loosening; refer to Figure 5 As shown, the thickness of the fastening pad 2a is at least 1mm, which can ensure the wear resistance of the fastening pad 2a. The strength of the fastening pad, the radius of the first half-round corner 2a1 is 1R, and the second half-round corner 2a2 is 0.5R; so that the first half-round corner 2a1 and the second half-round corner 2a2 are tangent to each other, so that the fastening pad 2a and the connecting flange 1b The strong integral connection improves the...

Embodiment 2

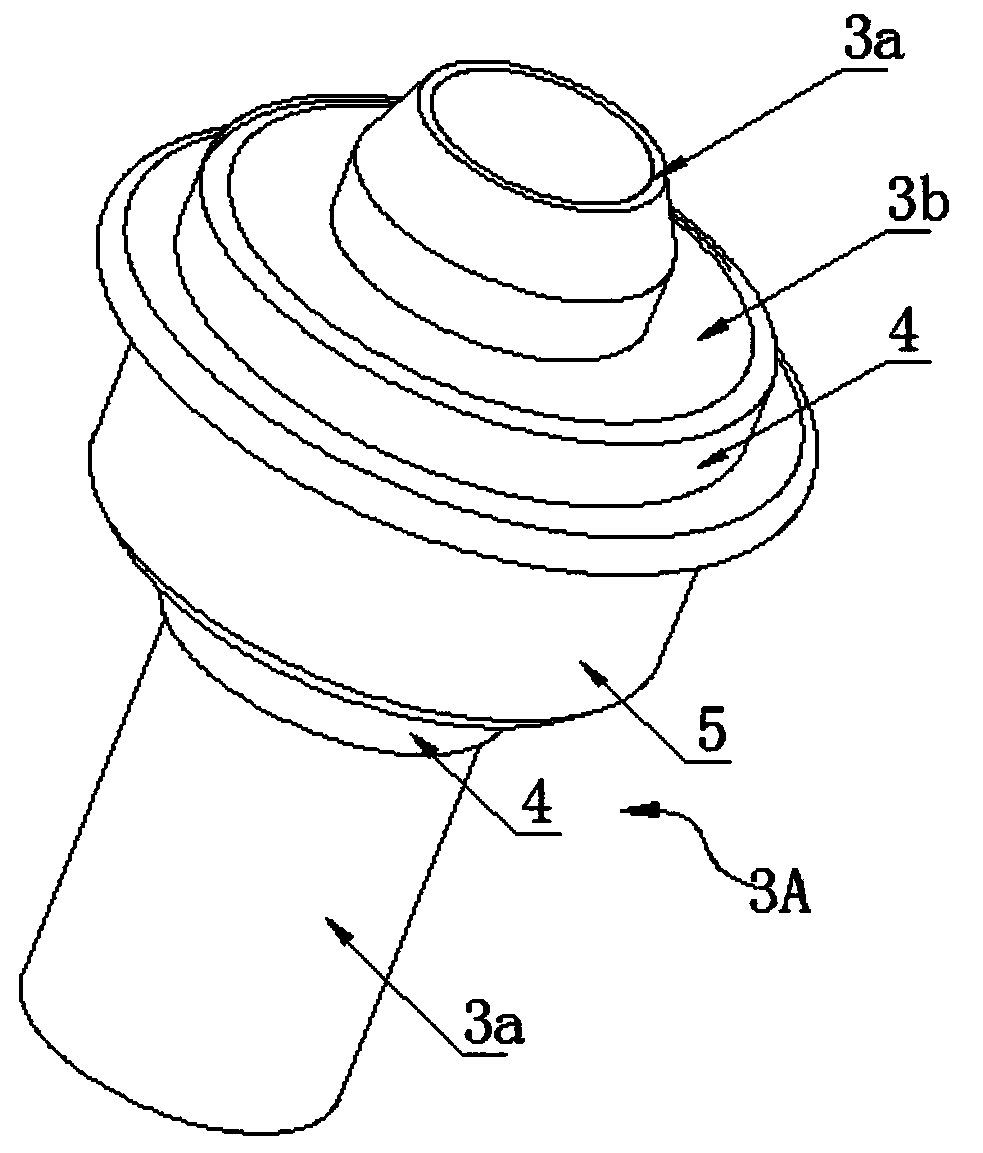

[0026] The second embodiment is: a new inner skeleton of the bushing, refer to Image 6 , Figure 7 with Figure 8 As shown, the fastening structure 2 also includes a friction assembly 2b, which is arranged on the A-fitting surface 1a0 of the fastening pad around the bushing connecting pipe 1a, thereby increasing the friction of the A-fitting surface 1a0 of the fastening pad, so that it is compatible with The mounting surfaces of the mounting bolts are tightly locked together to avoid slipping and loosening; the friction assembly 2b includes at least one circle of friction grooves 20, the cross section of the friction grooves 20 is a tooth-like structure, the depth of the friction grooves 20 is 0.1mm, and the number of friction grooves 20 5 friction grooves 20 are evenly distributed on the A assembly surface 1a0 of the fastening pad in turn, and the tooth spacing of each friction groove 20 is 0.5mm; refer to Figure 9 As shown, four friction grooves 20 are also provided on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com