Anchoring device for railway rail fastening assembly

An anchoring device, railway track technology, applied in the direction of track, rail holder, road, etc., can solve problems such as increased manufacturing cost, inability to remove anchoring device, complexity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

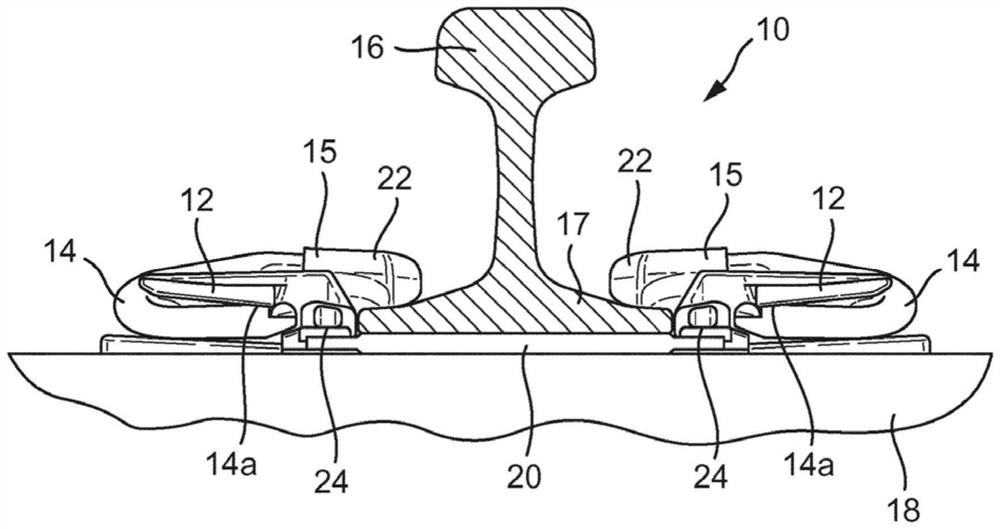

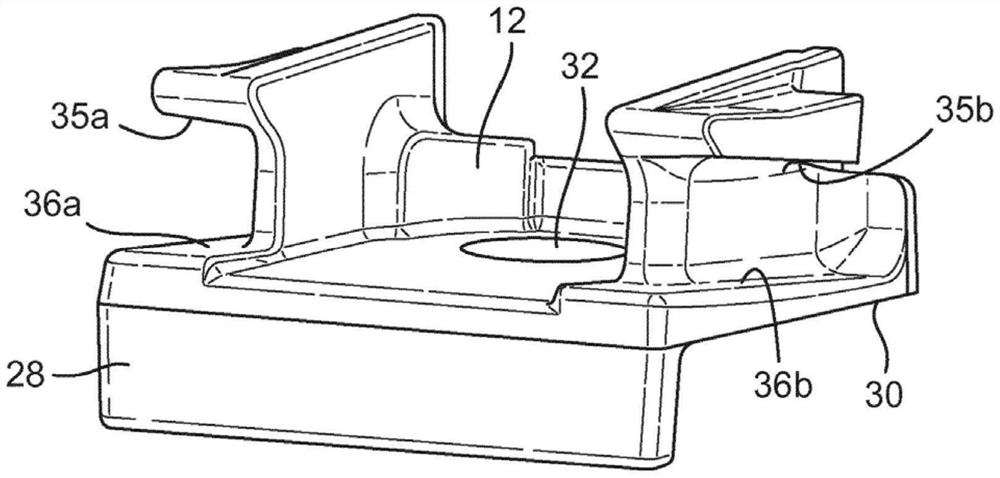

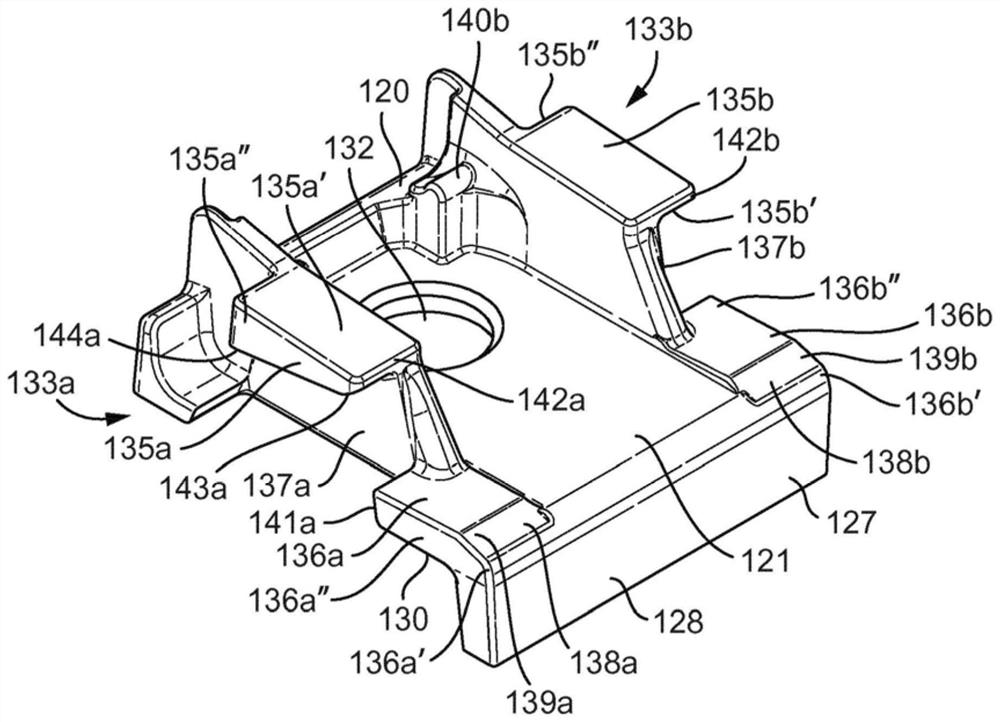

[0044] Referring to FIG. 2, an anchoring device 120 according to a first arrangement of the present application, such as a shoulder, may be formed as Figure 1a A portion of a railway track fastening assembly 10 is depicted. In other words, anchoring device 120 can replace Figure 1a Anchoring device 12 depicted in . As such, the anchor 120 is configured to receive a railroad track fastening fastener 14 and may be connected to an underlying subgrade 18, such as a railroad tie or slab. Corresponding anchoring devices 120 are provided on both sides of the railroad track 16 for holding the fastener 14 pressed on the rail foot 17 . Fastener 14 secures railroad track 16 to the subgrade below by the force exerted by the fastener on anchor 12 and track 16 .

[0045] The clasp 14 has first and second legs 14a and a rail "toe" 15 between the first and second legs 14a. The fastener 14 may be M-shaped, for example when viewed from above and when installed. The catch 14 may be configur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com