Algae recycling device

A technology for recycling and processing algae, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problem of high algae spoilage rate, achieve efficient cutting and shredding processing, efficient recovery, and avoid the increase in processing intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

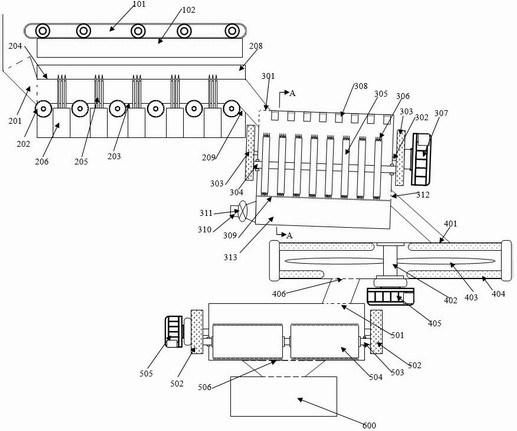

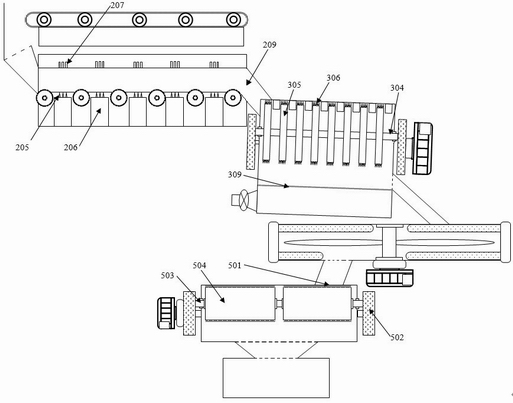

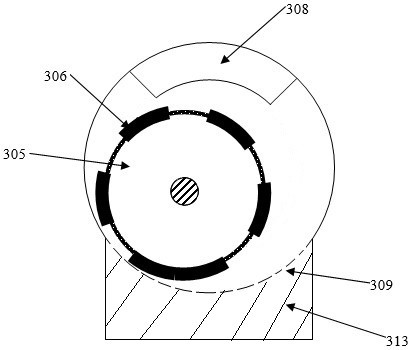

[0031] Further explanation in conjunction with accompanying drawings: Figure 1 to Figure 3 It is an algae recovery treatment device according to this embodiment, comprising a feeding part, a cutting part, a circumcision part, a drying part, a grinding part and a temporary storage box for finished products.

[0032] Such as figure 1 and figure 2As shown, the feeding part includes a feeding conveyor belt 101 and a water collection box 102. The feeding conveyor belt is a densely porous conveyor belt, and a water collection box is arranged below the feeding conveyor belt. The feeding part filters the water in the algae and removes it Collected in collection tank.

[0033] Such as figure 1 and figure 2 As shown, the cutting part includes a cutting chamber shell, a cutting chamber feed port 201, a conveying roller 202, a lower plate 203, an upper plate 204, a cutter 205, a cutter accommodating chamber 206, a cutter through hole 207, and an upper hollow. Cavity 208 and cuttin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap