Veneer restoration body colorimetric plate system and manufacturing method thereof

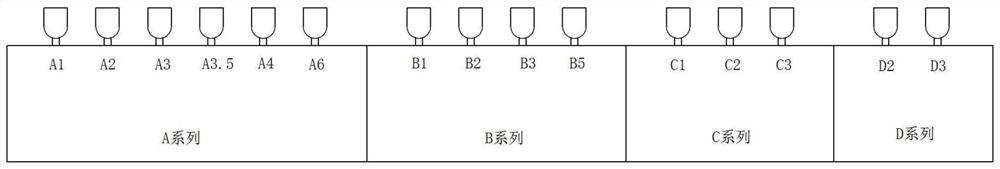

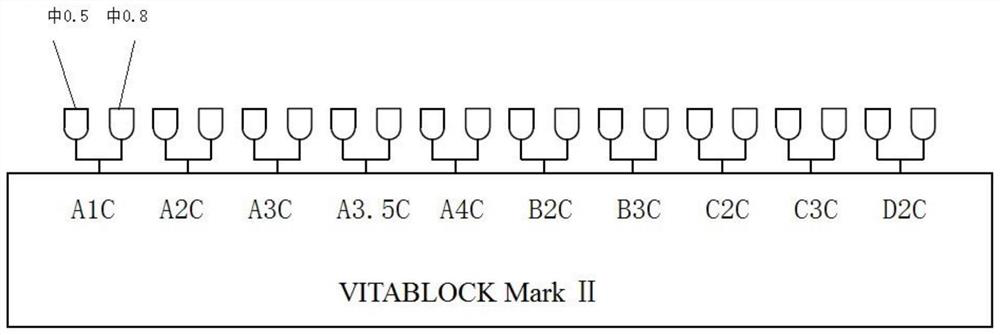

A production method and technology of color guides, which are applied in medical science, dentistry, etc., can solve problems such as the inability to meet the needs of clinical veneer color comparisons, and achieve accurate prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

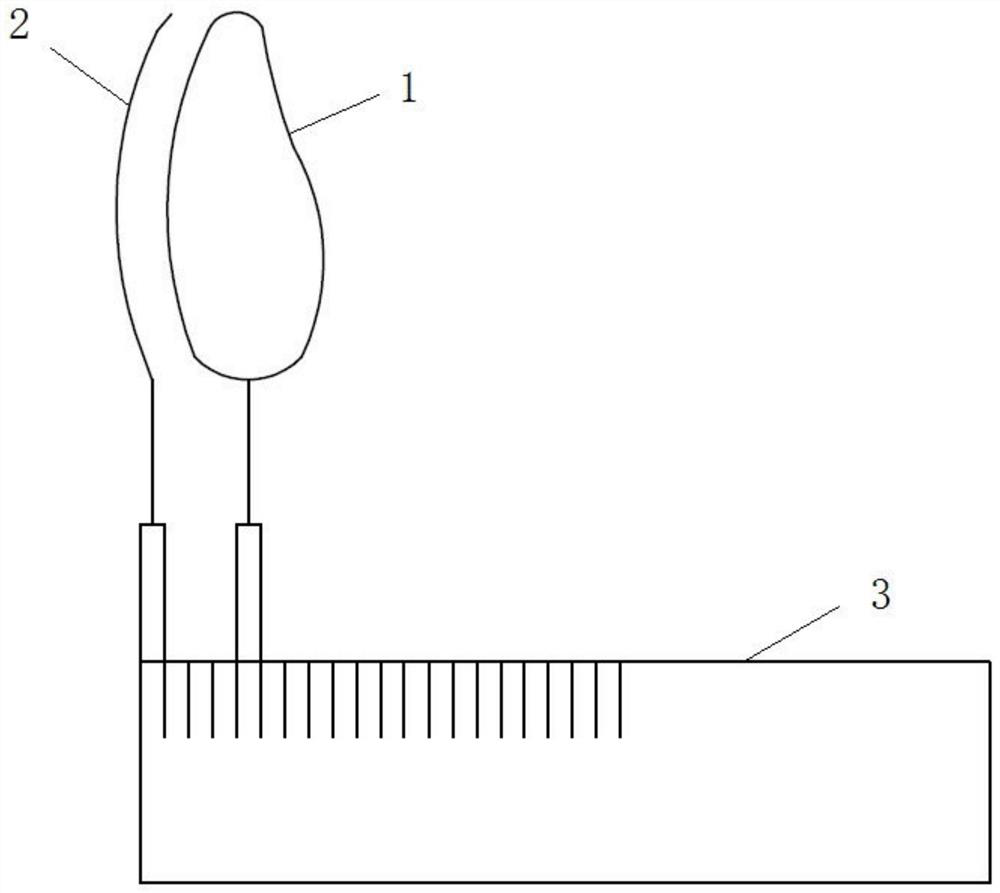

[0025] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but should not be used to limit the scope of the present invention.

[0026] The manufacturing method of the veneer restoration shade guide system of this embodiment comprises the following steps:

[0027] S1. Prepare the veneer on the standard tooth model to form the standard shape of the abutment teeth.

[0028] The right upper central incisor (Nisshin Corporation, Japan) of the standard tooth model was prepared with a veneer tooth preparation set (NTI-Set 1752, NTI-Kahla GmbH, Germany) for standard veneer preparation with a fenestration. 0.3mm, 0.5mm, 0.7mm. Because the tooth preparation of the anterior teeth veneer is prepared according to three parts of the lip, face and neck, the preparation amount of the neck 1 / 3-1 / 2 is small, generally 0.3-0.5mm, and 1 / 2-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com