Electronic component operation device and operation classification equipment applying same

A technology of electronic components and operating devices, which is applied in the direction of measuring devices, measuring device casings, connecting devices, etc., and can solve problems that affect the quality of electronic component testing and cannot be reliably contacted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] For a further understanding of the present invention, a preferred embodiment is hereby given in conjunction with the drawings, which are described in detail as follows:

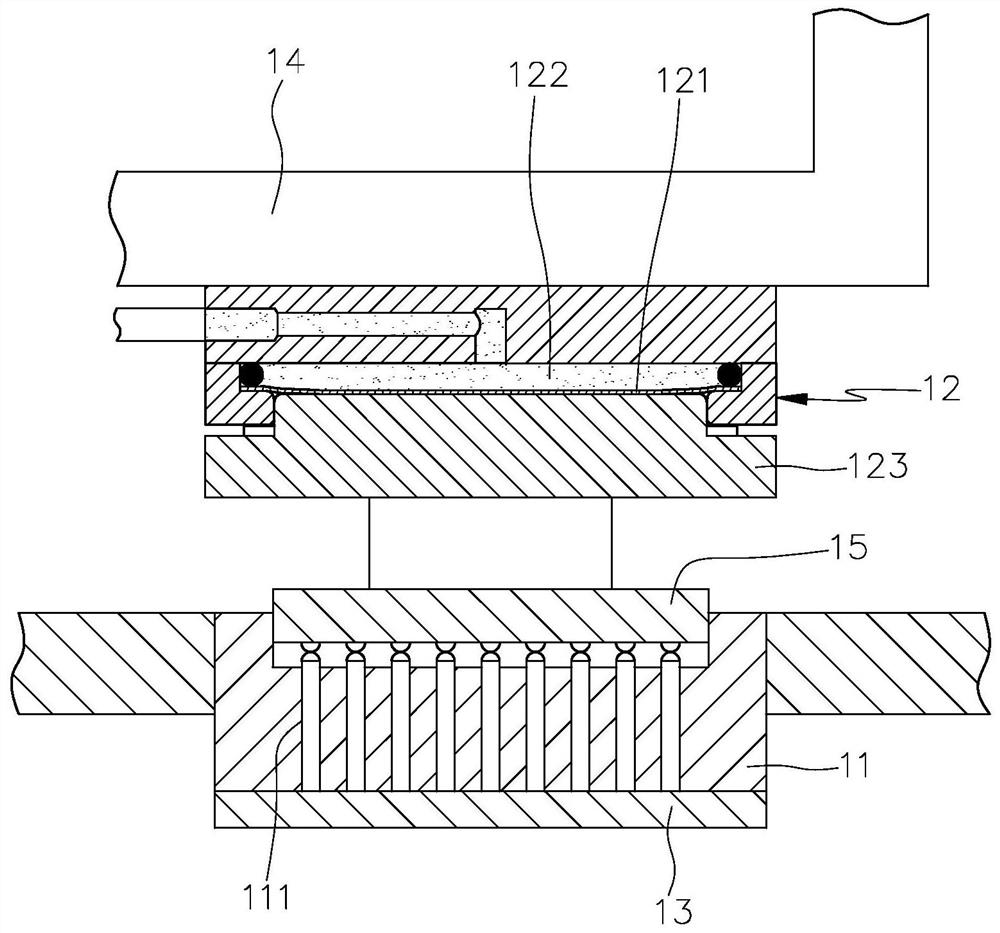

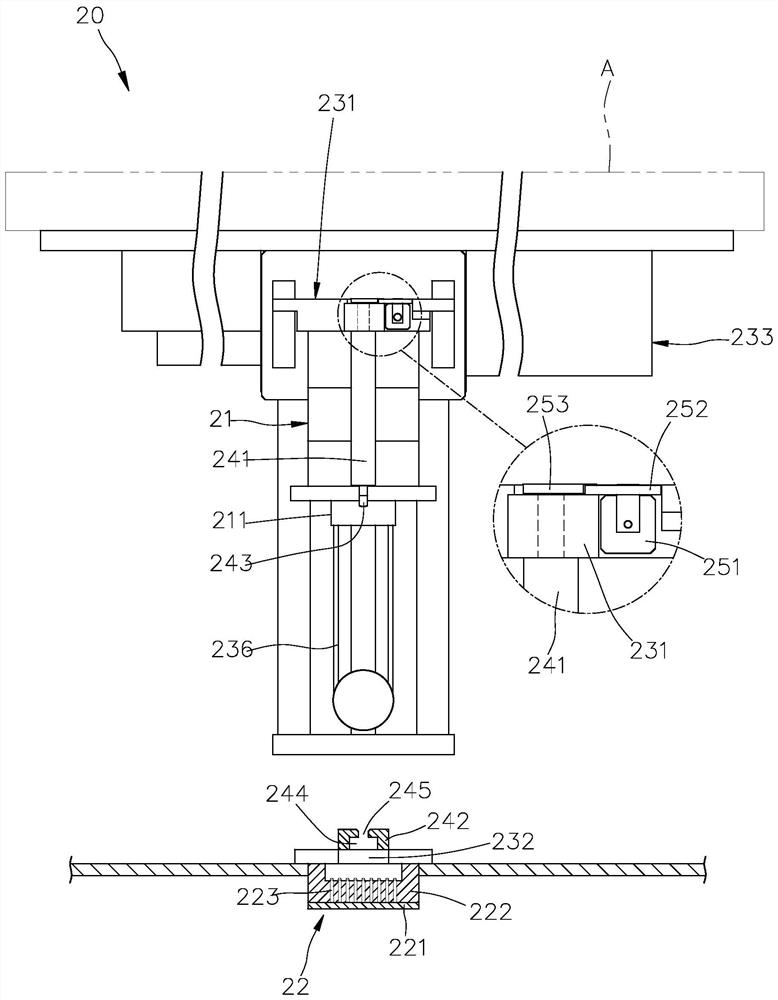

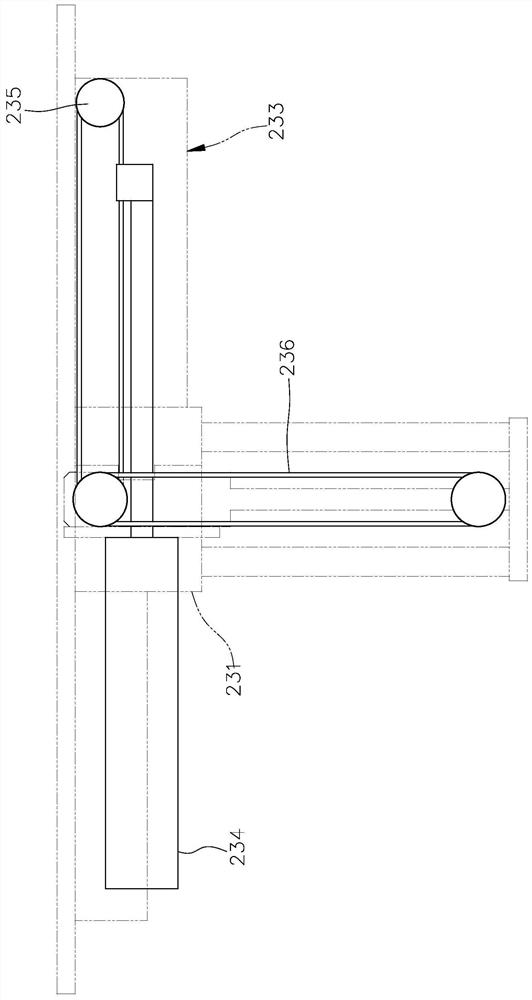

[0017] see figure 2 , image 3 , Figure 4 , the electronic component operation device 20 of the present invention includes at least one operator and actuating mechanism, the operator performs preset operations on the electronic components, further, the operator can be a crimping device, a tester, a printer, etc., in this embodiment Among them, the working device 20 includes a first working device and a second working device, the first working device is arranged in the actuating mechanism, and is a crimping device 21, and the crimping device 21 is provided with at least one crimping part 211 that can be displaced in the Z direction , to carry out the operation of pressing down the electronic components, and the other operating device 20 can be provided with a temperature controller on the crimping d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com