Automatic wire twisting and winding method and equipment

A kind of winding equipment and winding technology, which is applied in coil manufacturing, electrical components, inductance/transformer/magnet manufacturing, etc. It can solve the hidden dangers of quality, the position of hanging wire is easy to make mistakes, and the integration of automatic twisting and automatic winding cannot be realized. and other issues to achieve the effect of improving production efficiency and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings. It should be emphasized that the following descriptions are only exemplary and not intended to limit the scope of the present invention and its application.

[0020] In this embodiment, the component to be wound is a transformer skeleton as an example, and the wires to be wound are three-strand copper wires. It can be understood that, in addition to the transformer skeleton, it can also be other components to be wound that need to be wound, twisted and wound, and the wires to be wound can be other wires, such as gold wires and silver wires; The number of wires to be wound can be 2 strands, 4 strands or other multi-strand wires.

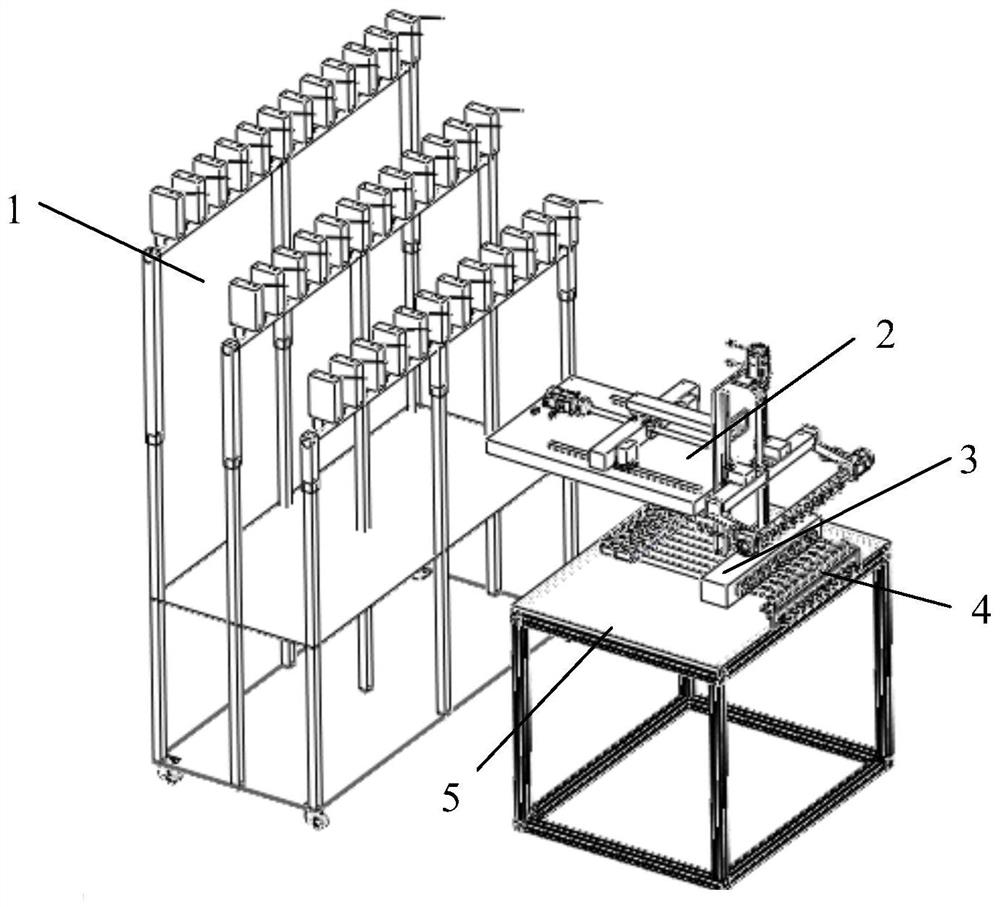

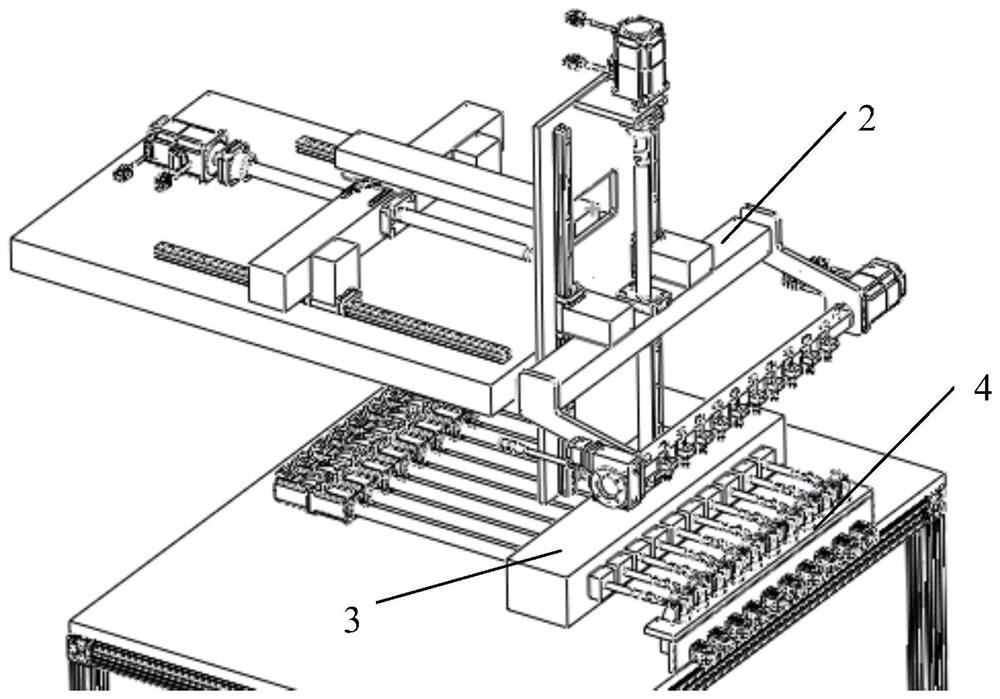

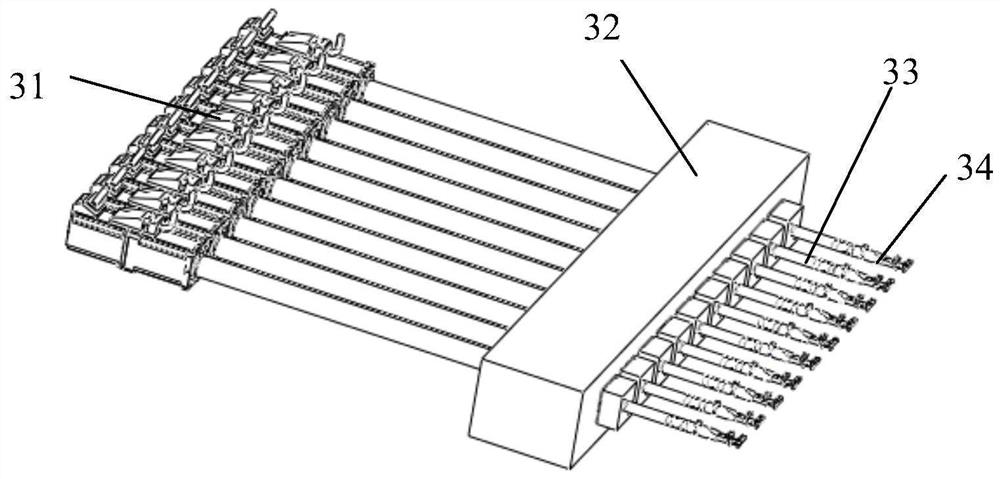

[0021] Such as figure 1 with 2 As shown, a transformer automatic stranding and winding equipment includes: a tension control unit 1 , a guide pin movement mechanism 2 , a winding spindle mec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap