Method for monitoring influence of water-cooled wall tube weld beading on tube wall safety

A water-cooled wall tube and water-cooled wall technology, applied in the combustion method, the safety device of the combustion chamber, the combustion chamber, etc., can solve the problems of different degrees of safety influence of the water-cooled wall tube, changes in fluid flow, and threats to the safe operation of the boiler.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0031] A method for monitoring the safety impact of water-cooled wall tube weld bumps on the tube wall, comprising the following steps:

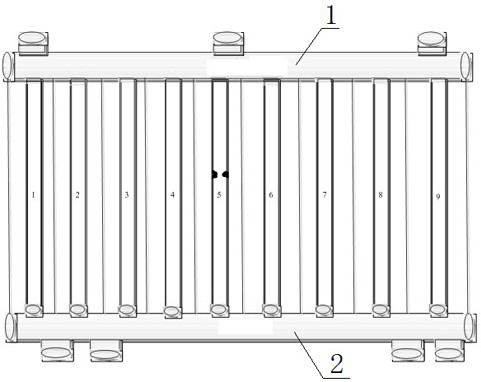

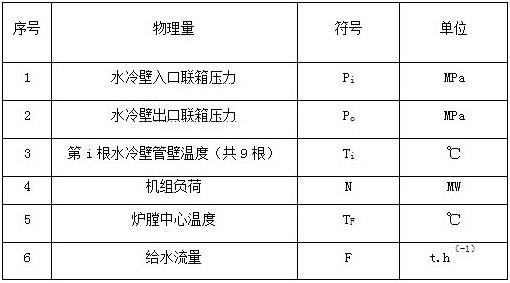

[0032] 1. Continuously collect the inlet and outlet header pressure of the water wall, the wall temperature of the water wall, the temperature of the furnace combustion center, the load of the unit and the flow rate of the feed water to obtain the collected data under each load condition, and check the validity of the collected data;

[0033] 2. Carry out three-dimensional flow and heat transfer calculations for water-cooled wall tube panels under each load condition;

[0034] In the calculation process of each load condition, a water-cooled wall tube in the water-cooled wall tube panel is taken as an object, and the shape of the weld bead in the water-cooled...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap