System and method capable of detecting remaining amount of paper of tissue machine

A technology for detecting paper towels and paper, applied in counting mechanisms/items, instruments, etc., can solve the problems of increased detection difficulty and cost, higher requirements for the sensing range of weight sensors, and inaccurate weight detection, so as to avoid display errors and facilitate Effects of repairing and avoiding counting errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

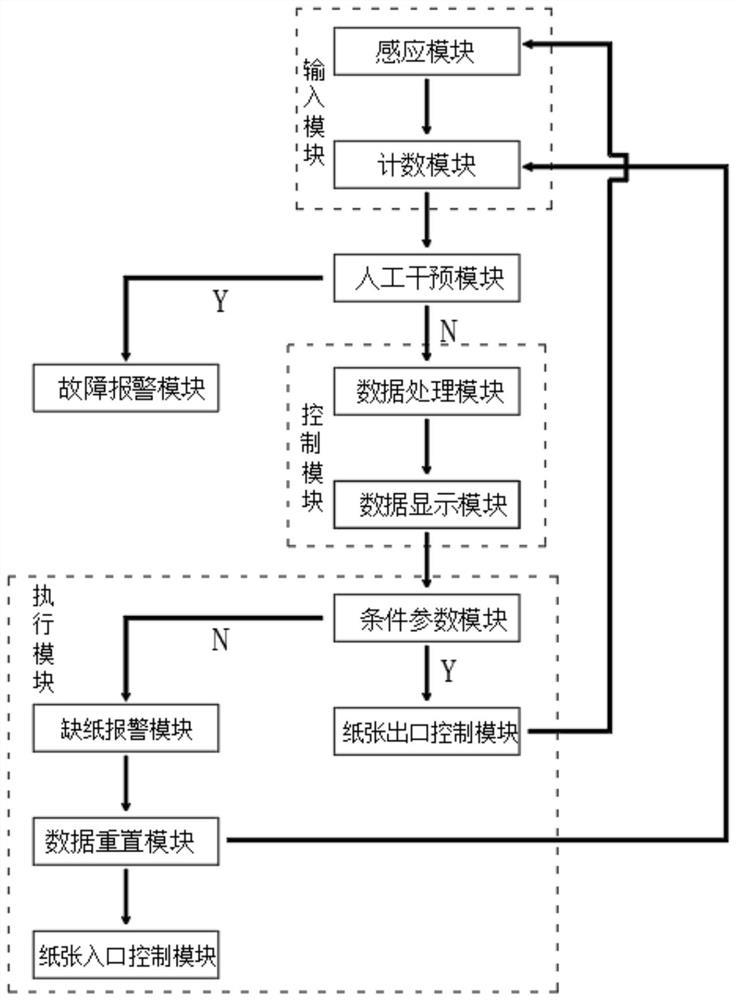

[0016] Such as figure 1 As shown, the present invention proposes a system that can detect the remaining amount of paper in a tissue machine, including an input module, a manual intervention module, a control module and an execution module, the input module includes a sensing module and a counting module, and the control module includes data A processing module and a data display module, the execution module includes a condition parameter module, a paper outlet control module, a paper-out alarm module, a paper inlet control module and a data reset module.

[0017] In an optional embodiment, the sensing module is located at the paper outlet, and is used to sense each paper output behavior, and the counting module is used to count each sensing of the sensing module, denoted as a.

[0018] In an optional embodiment, the manual intervention module is used for manual intervention to correct abnormal paper output behaviors such as paper jams, that is, the user performs a paper remova...

Embodiment 2

[0023] Such as figure 1 As shown, the present invention proposes a system that can detect the remaining amount of paper in a tissue machine, including an input module, a manual intervention module, a control module and an execution module, the input module includes a sensing module and a counting module, and the control module includes data A processing module and a data display module, the execution module includes a condition parameter module, a paper outlet control module, a paper-out alarm module, a paper inlet control module and a data reset module.

[0024] In an optional embodiment, the sensing module is located at the paper outlet, and is used to sense each paper output behavior, and the counting module is used to count each sensing of the sensing module, denoted as a.

[0025] In an optional embodiment, the manual intervention module is used for manual intervention to correct abnormal paper output behaviors such as paper jams, that is, the user performs a paper remova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com