A separate heating gas pressure calibration device with adjustable optical path

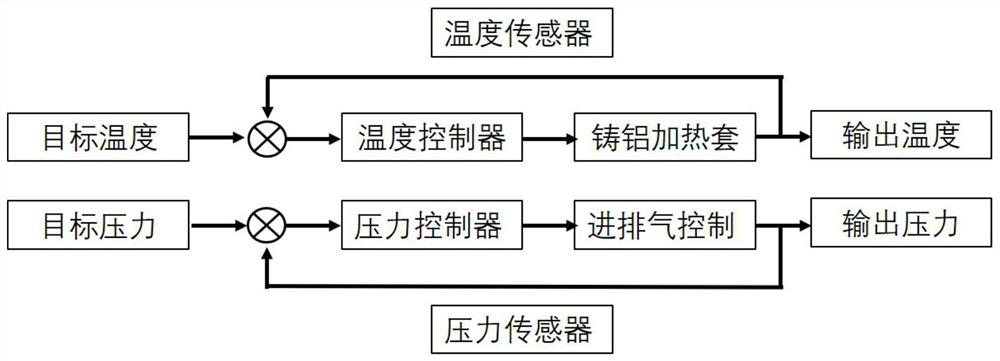

A technology for calibrating device and gas pressure, applied in the direction of measuring fluid pressure, measuring device, instrument, etc., can solve the problems of unreliable optical path system, inability to balance heating efficiency and device structure, etc., so as to solve the problem that heating efficiency and calibration device structure cannot be considered. , Adjustability expansion, the effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

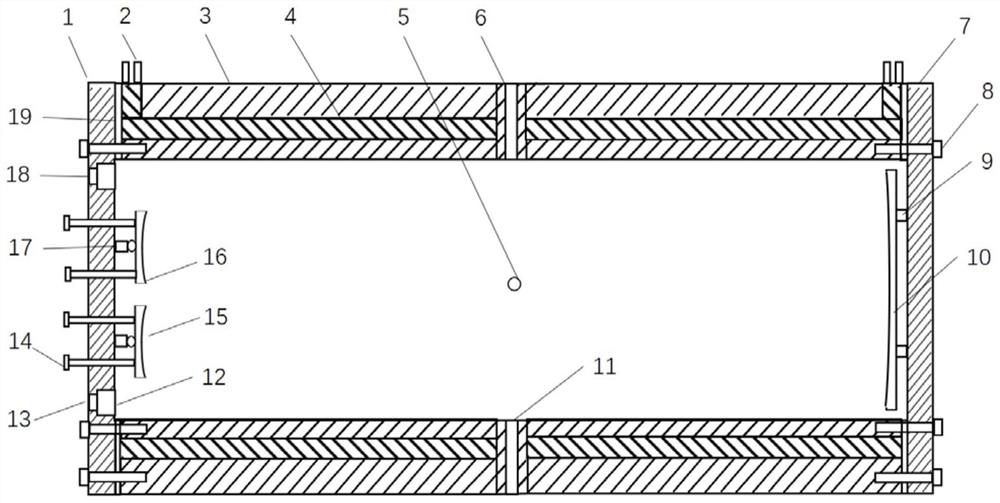

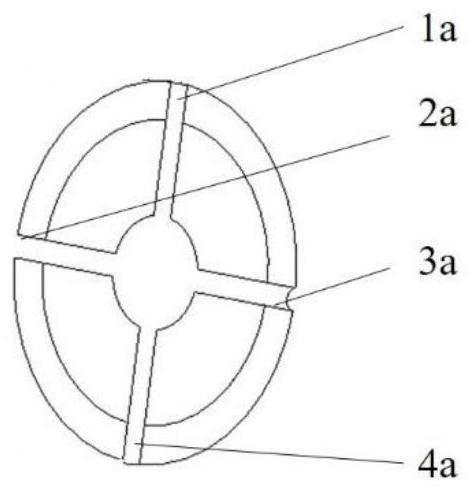

[0024] combine Figure 1~3 , a split heating gas pressure calibration device with adjustable optical path of the present invention includes: front cover 1, terminal block 2, cavity 3, built-in cast aluminum heating jacket 4, pressure sensor mounting hole 5, upper side temperature sensor Mounting hole 6, rear end cover 7, bolt 8, fixed support 9, first concave mirror 10, lower temperature sensor mounting hole 11, quartz glass 12, light inlet hole 13, adjustable screw 14, second concave mirror 15 , the third concave mirror 16 , the adjustable support 17 , the light exit hole 18 , and the sealing gasket 19 . The upper temperature sensor installation hole 1a, the pressure sensor installation hole 2a, the intake and exhaust holes 3a, and the lower temperature sensor installation hole 4a.

[0025] figure 1 It is the overall schematic dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com