Testing tool for testing rotation fluency of bearings with different sizes

A technology for testing tooling and fluency, applied in the field of bearing clamping, which can solve problems such as reducing the efficiency of bearing fluency testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

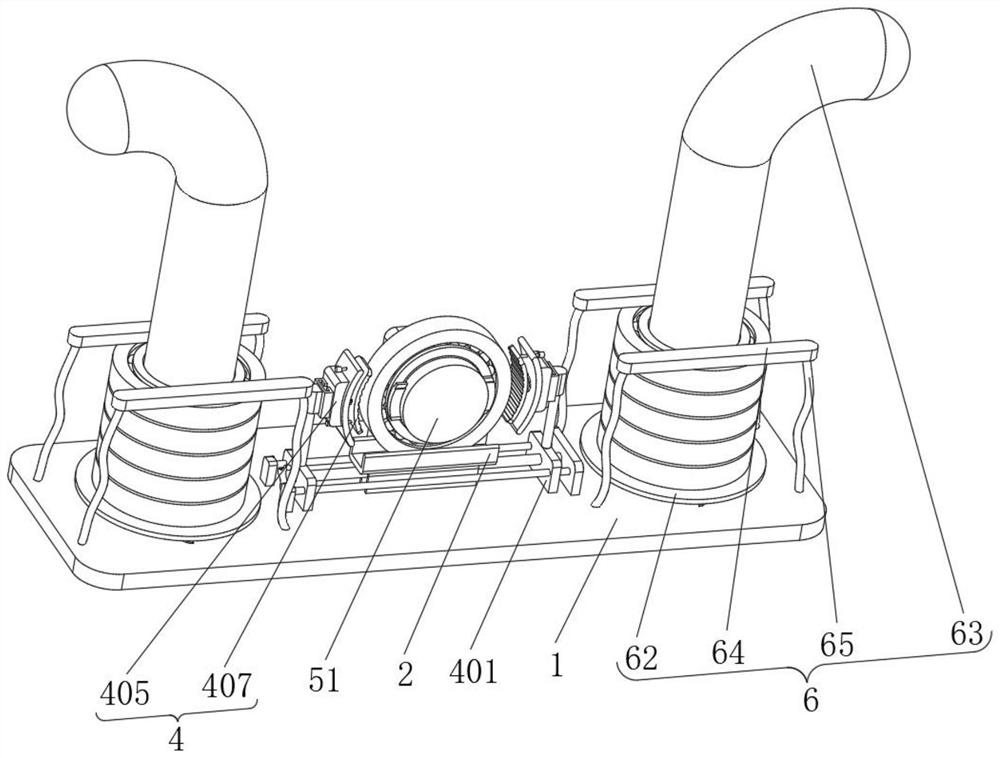

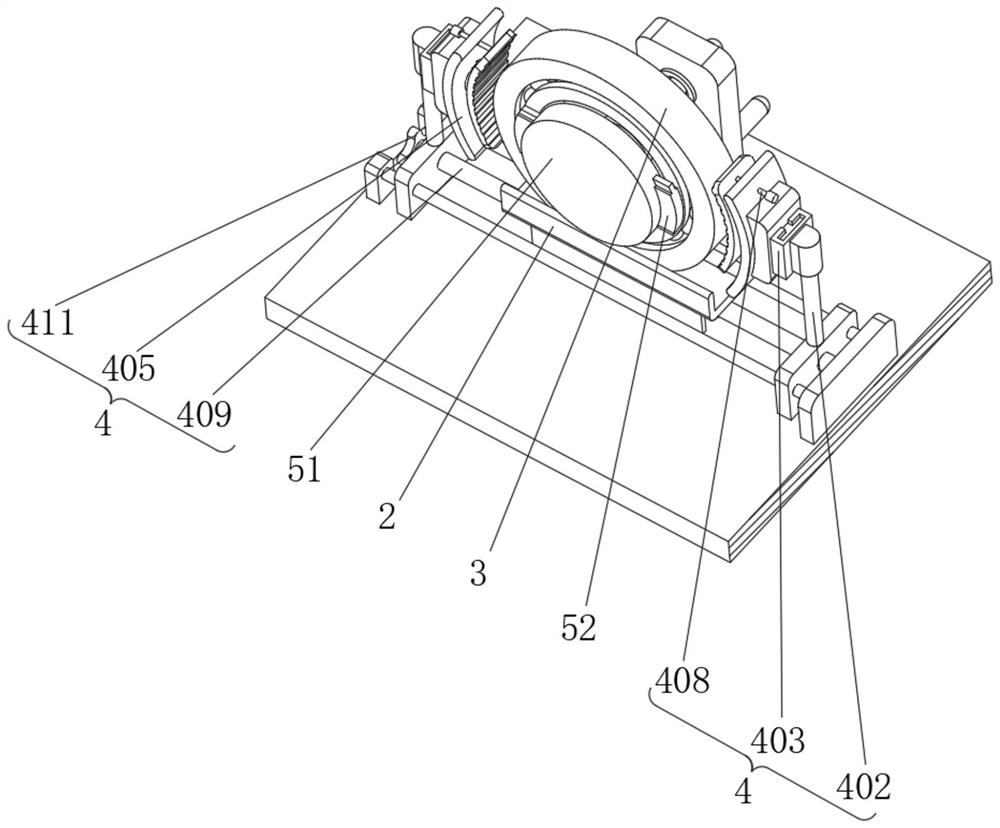

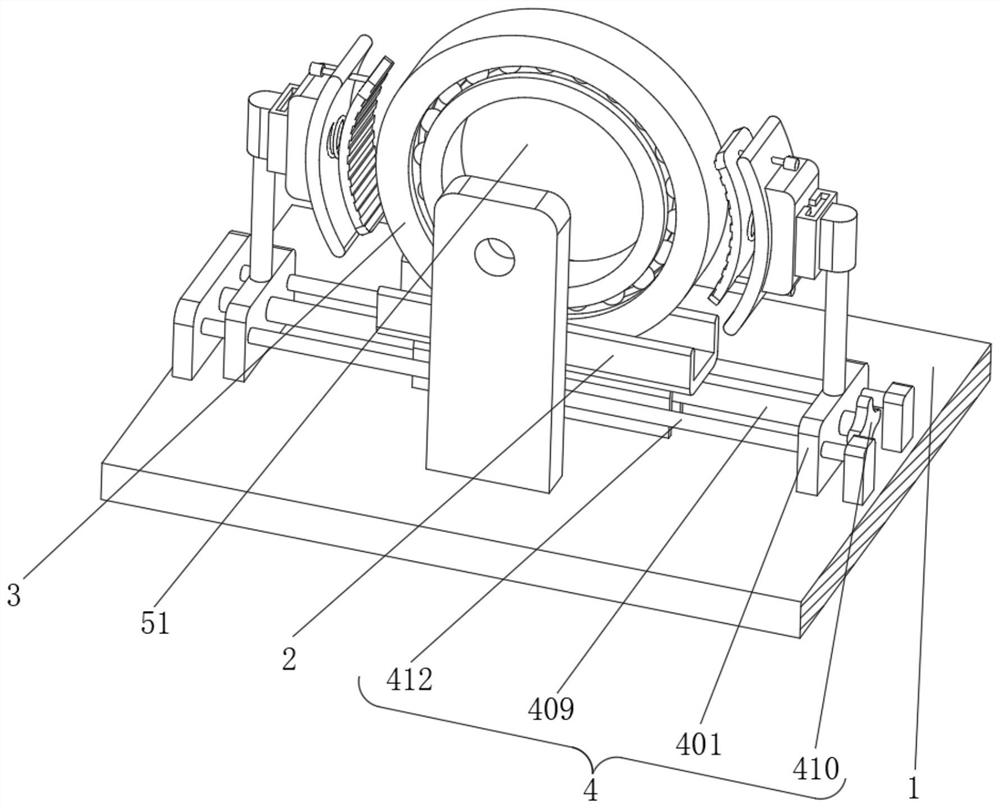

[0030] Example 1, such as Figure 1-8 As shown, the present invention provides a test tool for testing the smoothness of rotation of bearings of different sizes, including a backing plate 1 and a clamping device 4, a support plate 2 is fixedly installed on the upper surface of the backing plate 1, and the support plate 2 is away from One side of the backing plate 1 is slidingly connected with a bearing body 3 , the upper surface of the backing plate 1 is provided with a clamping device 4 , the inside of the bearing body 3 is provided with an auxiliary device 5 , and the upper surface of the backing plate 1 is provided with a storage device 6 .

[0031] The specific setting and function of the clamping device 4, the auxiliary device 5 and the storage device 6 will be described in detail below.

[0032] Such as image 3 with Figure 4 As shown, a support plate 2 is fixedly installed on the upper surface of the backing plate 1, and a bearing body 3 is slidably connected to the ...

Embodiment 2

[0038]Embodiment 2, on the basis of Embodiment 1, the storage device 6 includes a third spring 61, the lower end of the third spring 61 is fixedly connected to the backing plate 1, and the third spring 61 is evenly distributed on the surface of the backing plate 1, the third One end of the spring 61 away from the backing plate 1 is fixedly connected with a supporting plate 62, the supporting plate 62 is circular, and the inner wall of the supporting plate 62 is slidingly connected with a receiving rod 63, and the lower end of the receiving rod 63 is fixedly connected with the backing plate 1, and the receiving rod The upper end of 63 is arc-shaped, and the arc surface of receiving rod 63 is slidingly connected with pressing plate 64, and the two ends of pressing plate 64 are all fixedly connected with elastic cord 65, and the end of elastic cord 65 away from pressing plate 64 is fixedly connected with backing plate 1, the second The inside of the three springs 61 is slidingly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com