Constant velocity joint

A technology of constant velocity universal joints and universal joints, which is applied in the direction of elastic couplings, couplings, mechanical equipment, etc., can solve the problems of small opening angle increase rate and unfavorable ball cage, etc., and achieve reliable cage control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

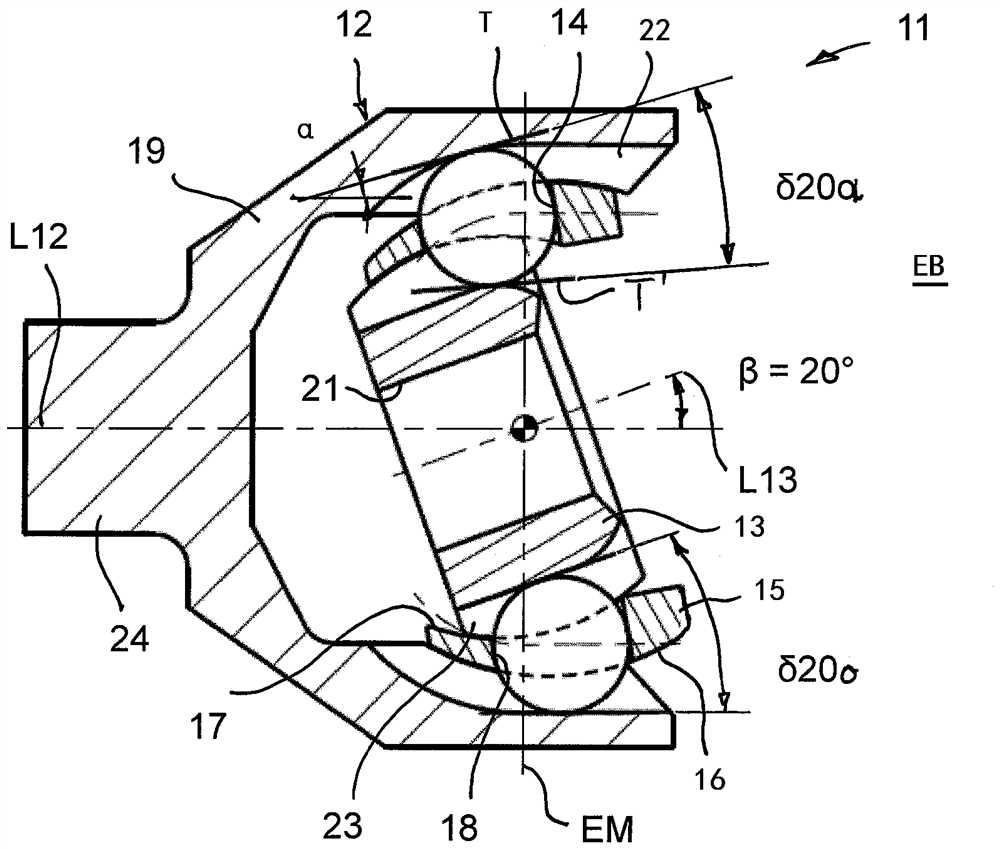

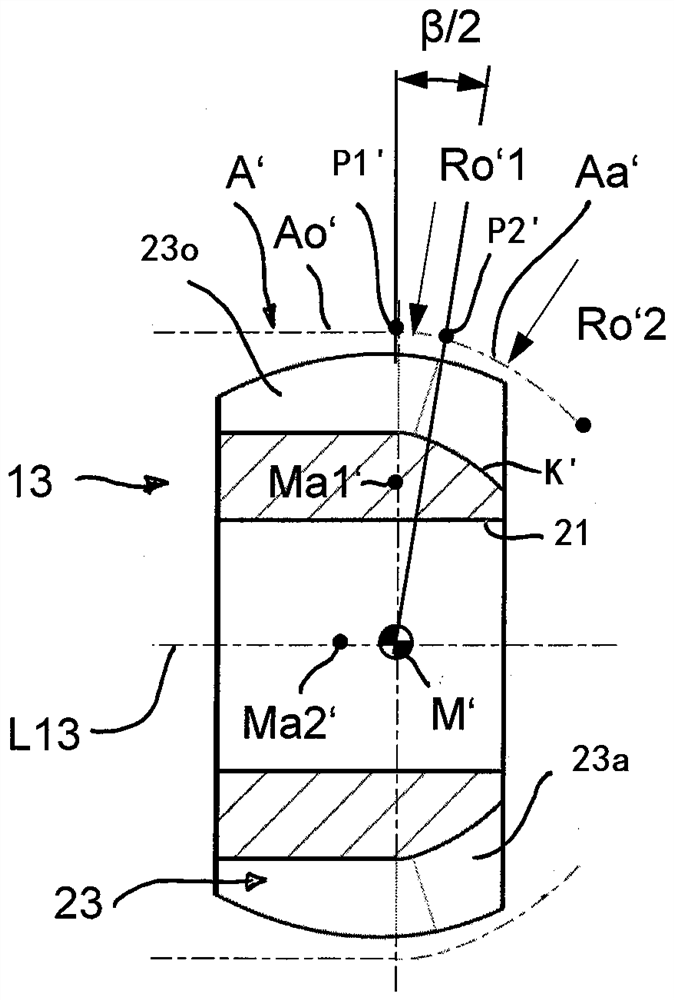

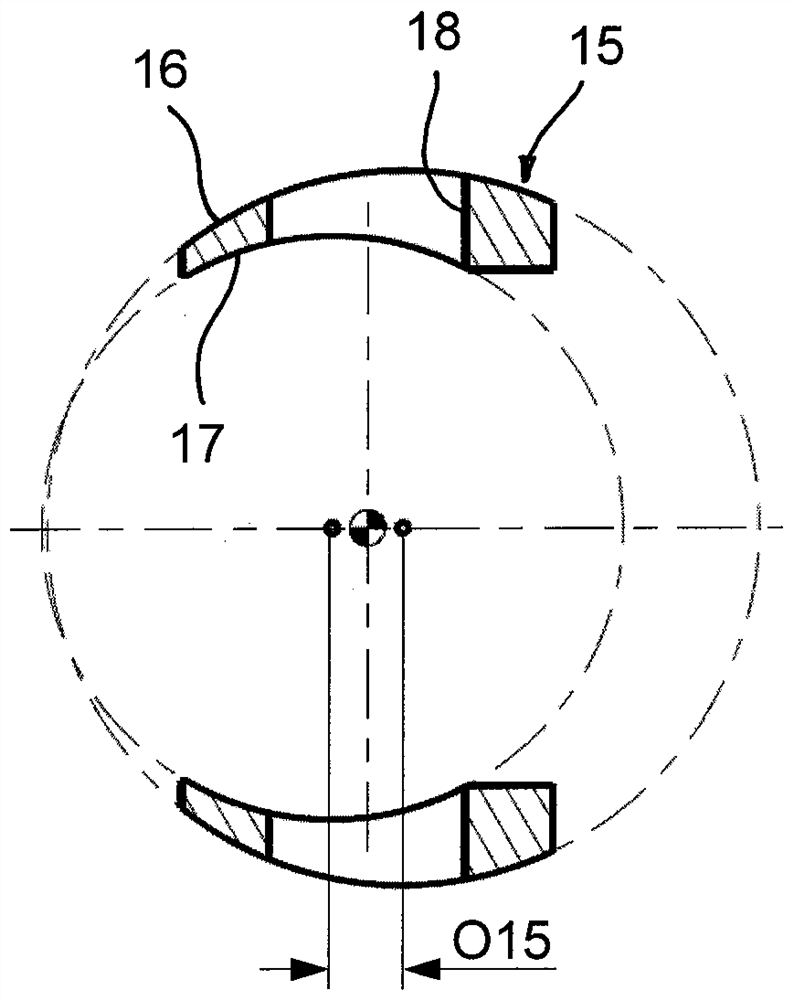

[0043] Commonly described below Figure 1A ) to 1G), Figure 2A ) to 2C) and image 3 . A constant velocity joint 11 according to the invention is shown. The constant velocity joint 11 includes a joint outer member 12 , a joint inner member 13 , balls 14 that transmit torque, and a ball cage 15 . The ball cage 15 has a spherical outer face 16 which is guided in the joint outer part 12 and a spherical cage inner face 17 which is guided on the joint inner part 13 . The balls 14 are held in the ball cage 15 in cage windows 18 distributed on the periphery in the joint center plane EM. The longitudinal axis L12 is marked at the joint outer part 12 and the longitudinal axis L13 at the joint inner part 13 . The point of intersection of the longitudinal axes L12, L13 and the joint center plane EM forms the center M of the joint.

[0044]The joint outer part 12 has a bottom 19 and an opening 20 to which a joint pin 24 is connected. The joint inner part 13 has an opening 21 into w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com