Ventilation device for electronic product assembly workshop

A technology for assembling workshops and ventilation devices, applied in space heating and ventilation, space heating and ventilation details, ventilation systems, etc., can solve problems such as poor ventilation effects, achieve the effect of improving work efficiency and increasing ventilation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

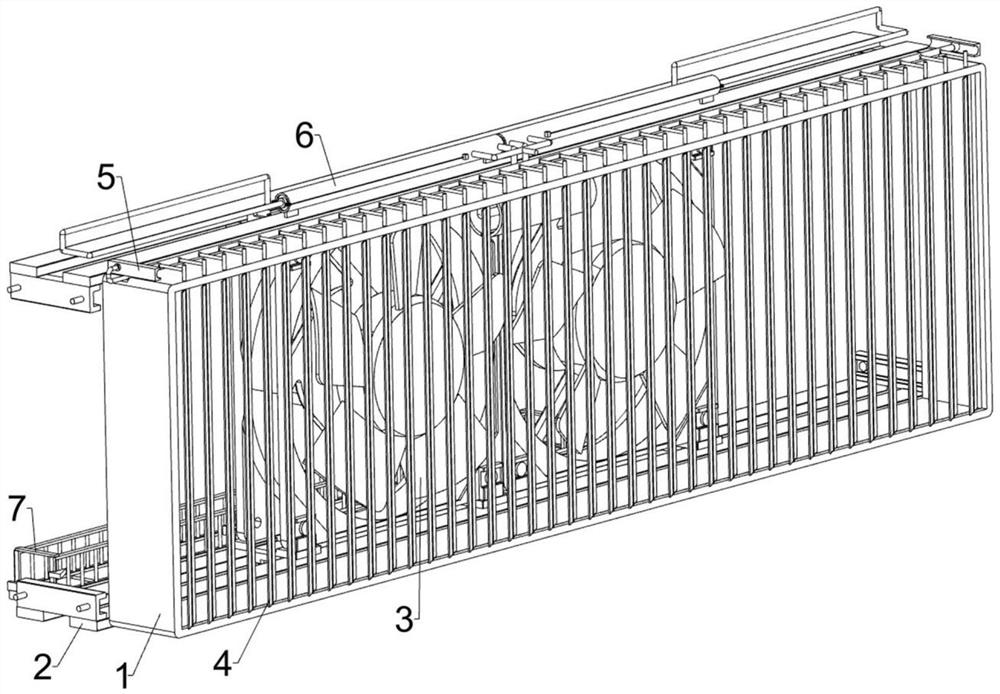

[0028] A ventilation device for an electronic product assembly workshop, such as Figure 1-3 As shown, it includes an installation frame 1 , a guide assembly 2 and a ventilation assembly 3 , the guide assembly 2 is provided on the rear side of the installation frame 1 , and the ventilation assembly 3 is provided on the guide assembly 2 .

[0029] When the workshop needs to be ventilated, the ventilation assembly 3 can be controlled to move to a suitable position on the guide assembly 2, and then the ventilation assembly 3 can be controlled to start working to ventilate the workshop. When ventilation is not required, the ventilation assembly can be controlled 3 stop working.

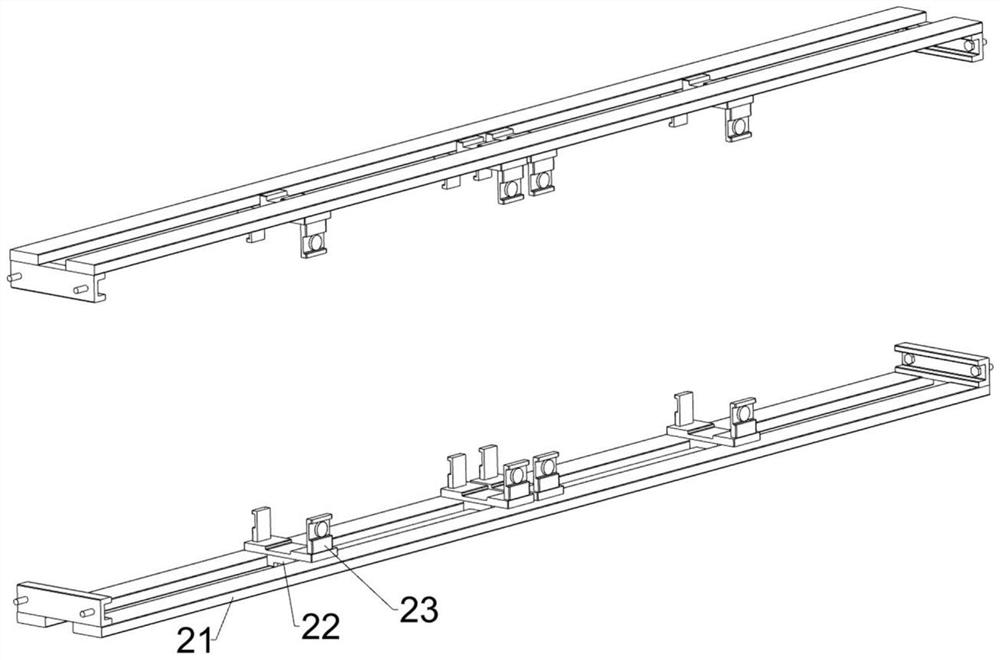

[0030] The guide assembly 2 includes a slide rail 21, a slide block 22 and a mounting plate 23, the upper and lower sides of the rear of the installation frame 1 are fixedly connected with the slide rail 21 by bolts, and two slide blocks 22 are slidably arranged on the slide rail 21. The two sliders 22 a...

Embodiment 2

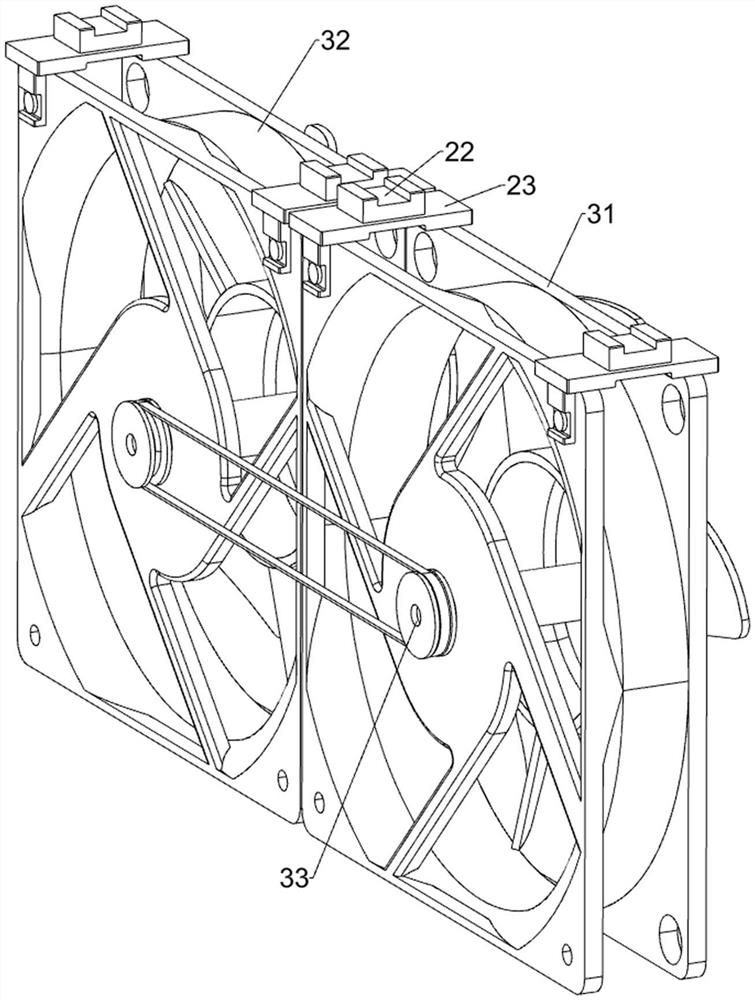

[0035] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, it also includes a direction changing assembly 4. The direction changing assembly 4 includes blades 41, connecting rods 42, balls 43 and pull rods 44. The front side of the installation frame 1 is rotatably provided with forty blades 41, and the upper parts of the blades 41 are connected to There are connecting rods 42, the rear sides of the connecting rods 42 are connected with balls 43, and the balls 43 are connected with pull rods 44 in a rotational manner.

[0036] When reversing ventilation is required, the pull rod 44 can be controlled to move left and right, and the movement of the pull rod 44 will drive the blade 41 to rotate through the ball 43 and the connecting rod 42, and the rotation of the blade 41 can perform reversing ventilation.

[0037] Also comprise convenient reversing assembly 5, conveniently reversing assembly 5 comprises slide ...

Embodiment 3

[0042] On the basis of Example 2, such as figure 1 with Figure 9 As shown, a moving assembly 7 is also included, and the moving assembly 7 includes a worm 71, a rotating shaft 72, a worm wheel 73, a rotary push rod 74, a connecting plate 75 and a railing 76, and the output shaft of the active suction fan 31 is connected with a worm 71 The rear side of the active suction fan 31 is rotationally connected with a rotating shaft 72, the upper part of the rotating shaft 72 is keyed to a worm wheel 73, the worm wheel 73 meshes with the worm screw 71, the lower part of the rotating shaft 72 is connected with a rotary push rod 74, and the lower slide rail 21 is behind Side is fixedly connected with connecting plate 75 by bolt, is provided with railing 76 slidingly on connecting plate 75, and railing 76 cooperates with rotary push rod 74.

[0043] When the active suction fan 31 is working, it will also drive the worm screw 71 to rotate, and the rotation of the worm screw 71 will drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com