Electromagnetic detection probe for deep defects of metal component based on TMR magnetoresistive sensor array

A magnetoresistive sensor and electromagnetic detection technology, applied in magnetic sensor arrays, material analysis through electromagnetic means, instruments, etc., can solve the problems of restricting the development of eddy current detection and the weakening of probe sensitivity, so as to improve the relative change rate, improve sensitivity, Avoid the effect of mutual induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

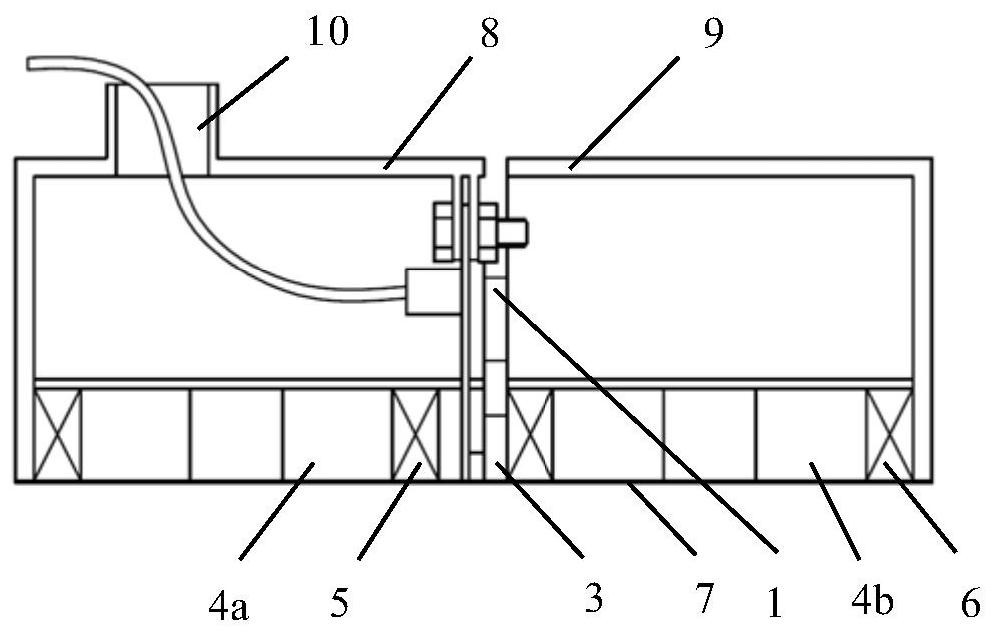

[0083] Taking the deep defects of TC4 plate as the research object, the electromagnetic detection probe for deep defects of metal components based on the TMR magnetoresistive sensor array of the above invention is used to detect them. The length, width and height of the measured defect are 4mm×0.2mm×2mm, and the defect is located at a depth of 3mm below the surface of the TC4 specimen. In the experiment, the signal generator applies a 0.2A sinusoidal signal to the excitation coil, and the excitation frequency is 1kHz to 10kHz.

[0084] Experimental results:

[0085] The present invention has detected the defect under 3mm of TC4 deep layer preferably, and its result to defect detection under the excitation of 5kHz, 0.2A sinusoidal signal is as follows Figure 5 shown, from Figure 5 It can be seen from the figure that under the excitation of double rectangular coils, the signal collected by the TMR array is maintained at a small level at the position without defects; when the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com