Steel structure clamping and fixing device capable of manually adjusting clamping angle

A manual adjustment, clamping and fixing technology, applied in the field of steel structures, can solve problems such as troublesome operation, affecting work efficiency, and inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

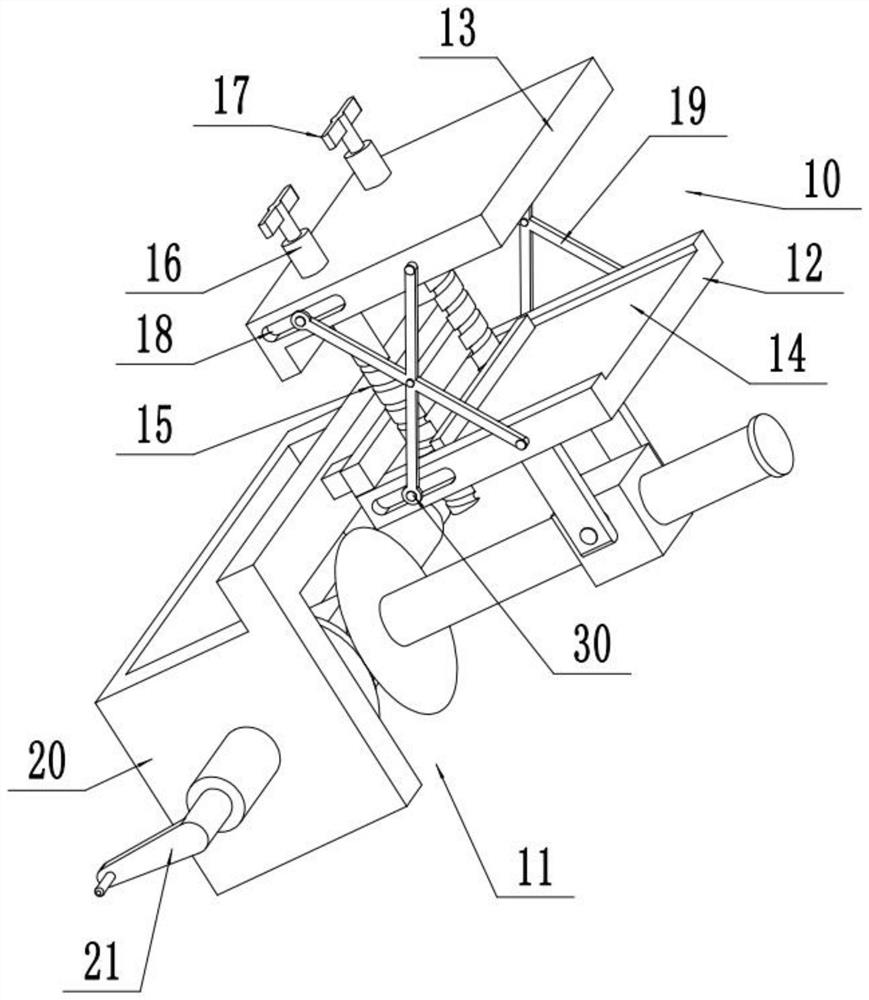

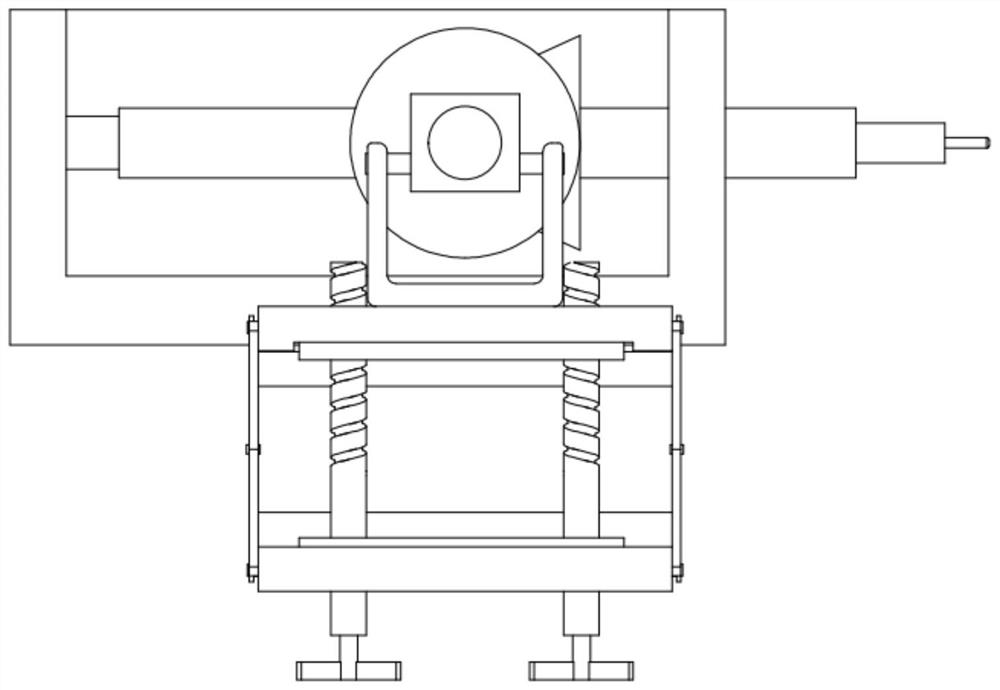

[0019] see Figure 1-4 , a steel structure clamping and fixing device that can manually adjust the clamping angle, including a clamping mechanism 10, an adjusting mechanism 11, a fixed splint 12, and a movable splint 13; the clamping mechanism 10 includes two sets of opposite fixed splints 12 and The movable splint 13, the lower part of the front and rear side walls of the fixed splint 12 and the movable splint 13 are provided with a waist-shaped chute 18, and the inside of the chute 18 is slidably connected with a slider 30, and the left and right side walls of the fixed splint 12 and the movable splint 13 are respectively The two groups of connecting rods 19 connected by the middle part are connected, and the bottom ends of the connecting rods 19 are respectively connected to the sliders 30 inside the two groups of chute 18, and the top ends of the connecting rods 19 are connected to the fixed splint 12 and the movable splint 13. On the side wall, the fixed splint 12 and the...

Embodiment 2

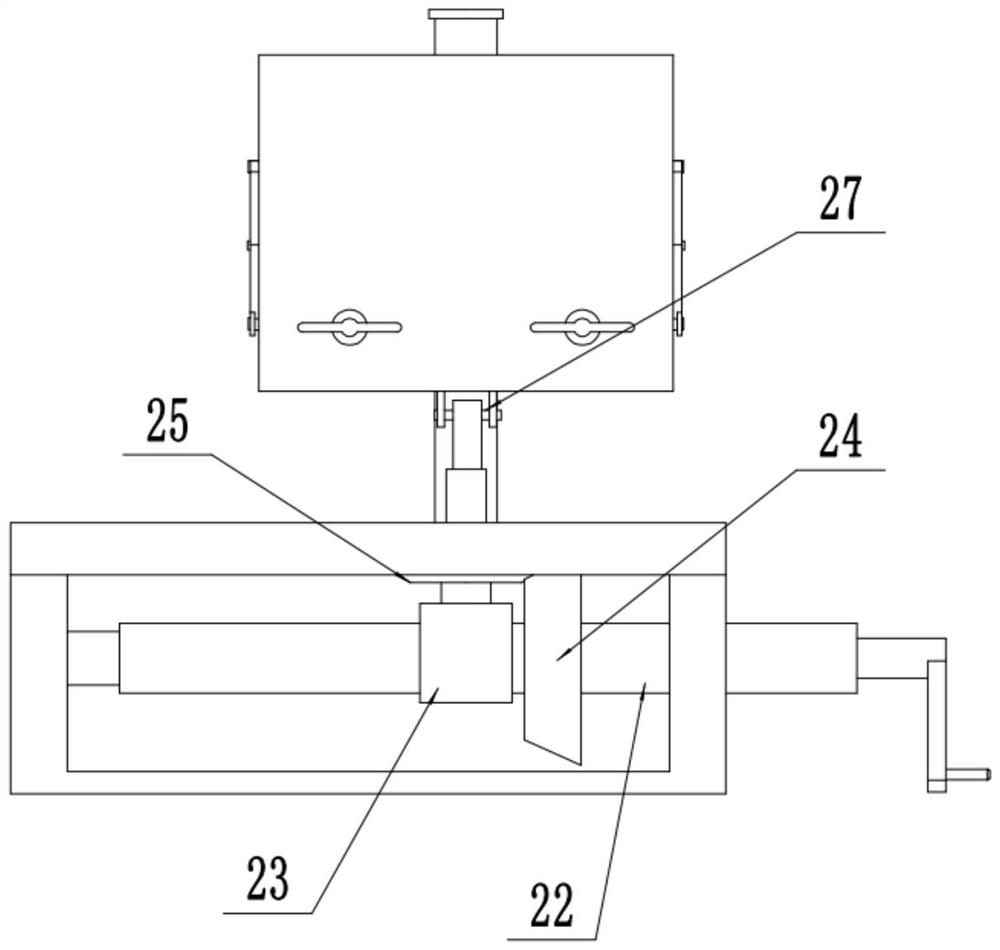

[0023] refer to Figure 5 , on the basis of Embodiment 1, baffles 31 are symmetrically installed on the inner sides of the fixed splint 12 and the movable splint 13, which are close to the clamping groove 14, and the baffles 31 are set to block the steel structure during clamping. Touch the adjustment screw-15 and other parts. Two groups of fastening plates 32 are arranged symmetrically on the front and rear sides of the inside of the clamping groove 14, rubber pads are fixedly installed on the opposite sides of the fastening plates 32, and an adjusting screw 2 33 is fixedly installed on the middle of the outer side of the fastening plate 32. Adjusting screw 2 33 is threadedly connected with internal thread groove 35 provided in clamping groove 14, and the outer end of adjusting screw 2 33 is fixedly equipped with rotating handle 3 34, and two groups of fastening plates 32 are approached by rotating rotating handle 3 34 , so that it can be used for steel structures of differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com