Wire-driven snake-shaped arm robot capable of realizing bending motion decoupling

A technology of bending motion and robotics, applied in the field of robotics, can solve problems such as increasing the difficulty of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

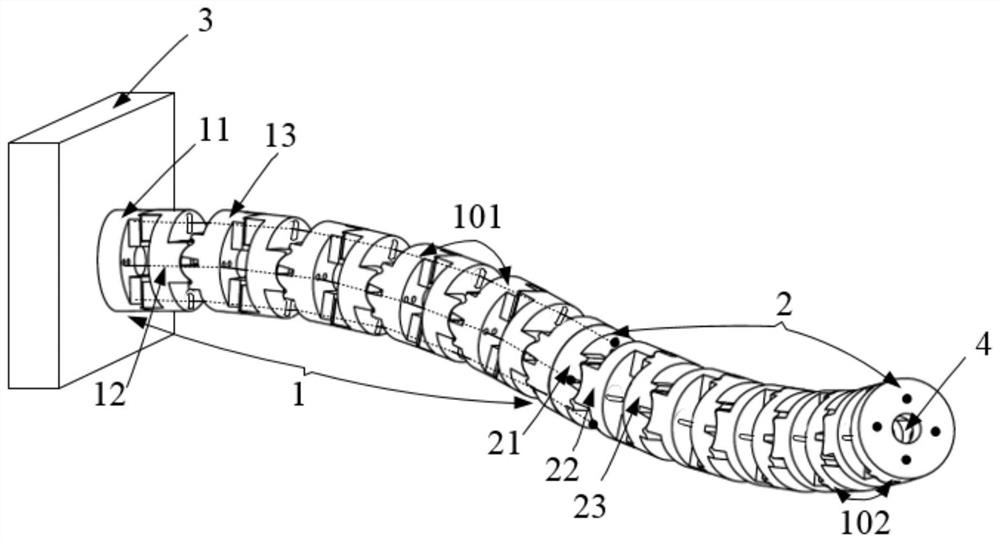

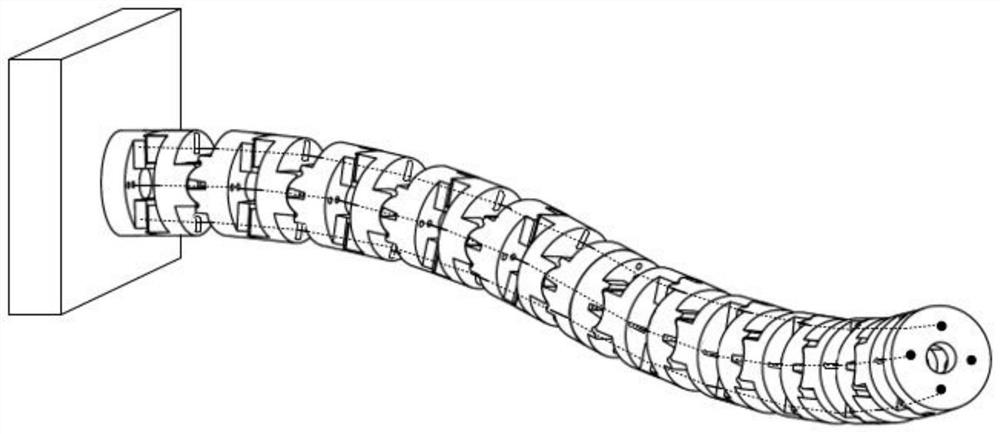

[0053] As shown in Figures 1 to 3, this embodiment discloses a wire-driven snake-arm robot that can realize decoupling of bending motion, including

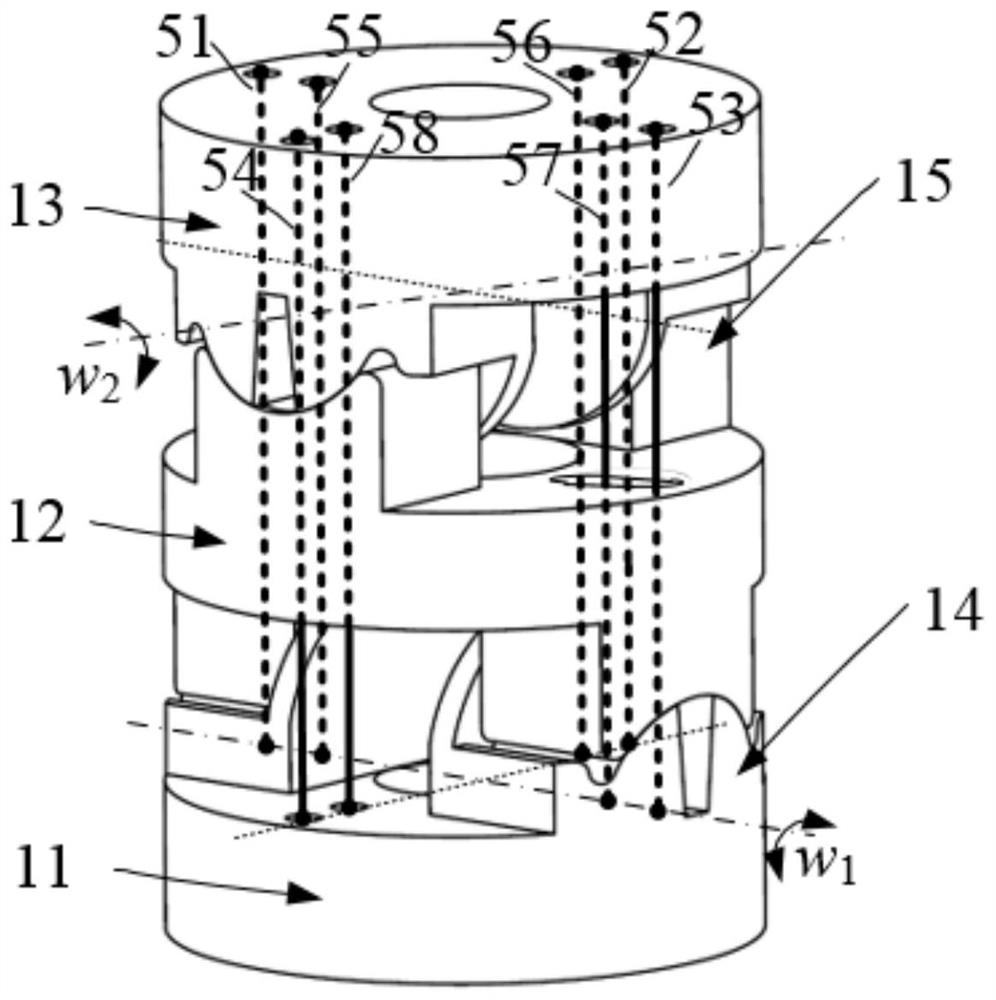

[0054] The proximal joint 1 includes a proximal joint 101; the proximal joint 101 includes a proximal base plate 11, a proximal link 12 and a proximal end plate 13, and the proximal base plate 11 is connected to the proximal joint. The rods 12 are connected to form a first rotation pair 14, the rotation axis of the first rotation pair 14 coincides with the end surface of the proximal base plate 11; the proximal end plate 13 and the proximal connecting rod 12 form a second rotation pair 15, the rotation axis of the second rotating pair 15 coincides with the end face of the proximal end disk 13;

[0055] The distal joint 2 is fixedly connected with the proximal joint 1; the distal joint 2 includes a distal joint 102, and the distal joint 102 includes a distal base plate 21, a distal connecting rod 22 and a distal The end disk 23, ...

Embodiment 2

[0084] This embodiment discloses a wire-driven serpentine arm robot capable of decoupling bending motion, which includes a proximal joint 1 and a proximal joint 101; the proximal joint 101 includes a proximal base plate 11, a proximal The connecting rod 12 and the proximal end disk 13, the proximal base disk 11 is connected with the proximal connecting rod 12 to form a first rotating pair 14, the rotation axis of the first rotating pair 14 is connected to the proximal base disk 11 The end faces are coincident; the proximal end disc 13 and the proximal connecting rod 12 form a second rotating pair 15, and the rotation axis of the second rotating pair 15 coincides with the end face of the proximal end disc 13;

[0085] The distal joint 2 is fixedly connected with the proximal joint 1; the distal joint 2 includes a distal joint 102, and the distal joint 102 includes a distal base plate 21, a distal connecting rod 22 and a distal The end disk 23, the distal base disk 21 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com