High-precision open type robot moving carrier and high-precision moving method thereof

An open robot and mobile carrier technology, applied in the field of robot movement, can solve the problems of large movement problems, insufficient friction between the wheel body and the roadblock surface, and large limitations, and achieve the reduction of movement restrictions, flexible and fast maneuvering requirements, Extend the effect of mobile selection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

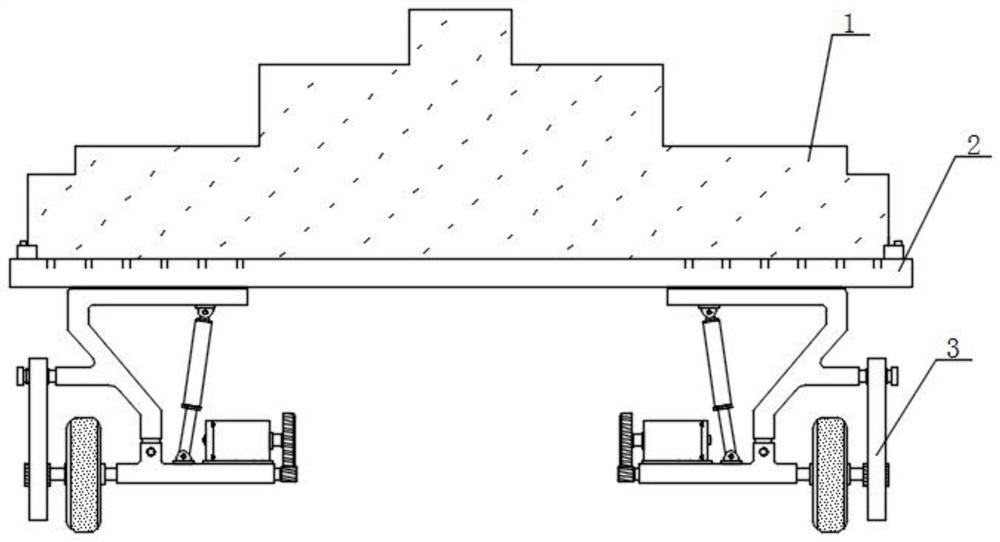

[0030] like Figure 1-2 As shown, the high-precision robot mobile carrier includes a loading plate 2 and a robot 1, the top of the loading plate 2 is fixedly connected with the robot 1, and the bottom end of the loading plate 2 is fixed with a mobile component 3;

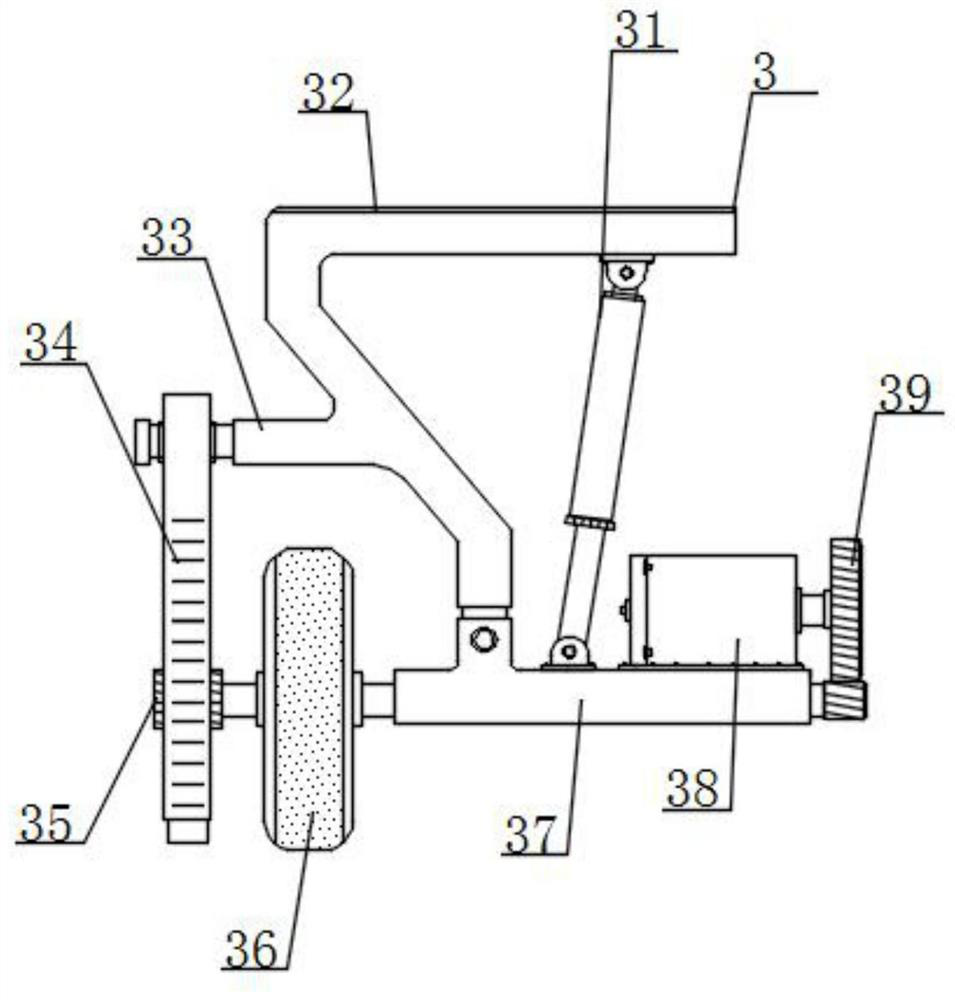

[0031] The mobile assembly 3 includes a V-shaped plate 32, four V-shaped plates 32 are fixed at the four peripheral corners of the bottom end of the carrying plate 2, a support plate 37 is arranged below the V-shaped plate 32, and a U-shaped groove is fixed on the top of the support plate 37 One end of the V-shaped plate 32 is set in the U-shaped groove, and the V-shaped plate 32 is rotatably connected to the U-shaped groove; the inclined side wall of the V-shaped plate 32 is fixed with a support arm 33, and the support arm 33 is provided with an obstacle-crossing The equipment 34, the obstacle-crossing equipment 34 is set on the support arm 33; the obstacle-crossing equipment 34 is interspersed with a gear 35, and ...

Embodiment 2

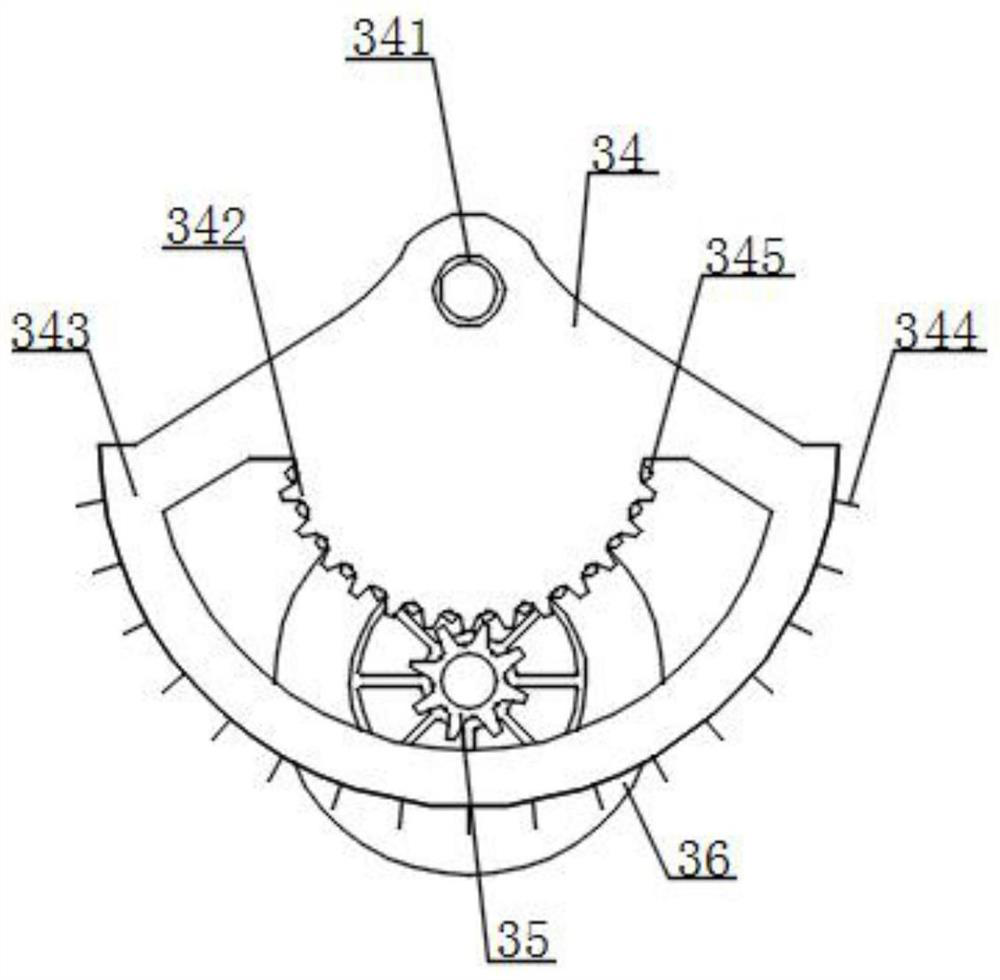

[0037] like image 3 As shown, the high-precision robot moves the carrier, and the obstacle-crossing equipment 34 includes a perforation 341, a rack 342 and a fan-shaped obstacle-crossing box 343. The center of the fan-shaped obstacle-crossing box 343 runs through a perforation 341. The obstacle crossing box 343 is provided with a fan-shaped slot, and a rack 342 is fixed on the upper edge of the fan-shaped slot, and the rack 342 is located above the gear 35 .

[0038]In this embodiment, in the obstacle-crossing movement mode, the moving form of the robot 1 is crawling, that is, when the gear 35 is meshed and connected to the rack 342, based on the kinetic energy released by the drive unit 38, the fan-shaped obstacle-crossing box 343 is relatively Rotate on the road surface; during the rotation process, based on the four obstacle-climbing equipment 34, the ground contact and suspension adjustment are carried out through the hydraulic mechanism 31, and then under the repeated ad...

Embodiment 3

[0040] like Figure 4-5 As shown, the high-precision robot moves the carrier, and the obstacle-crossing equipment 34 includes an execution structure 344 and a trigger structure 345. The inside of the fan-shaped obstacle-crossing box 343 is fixed with a trigger structure 345 above the fan-shaped slot, and the trigger structure 345 is inserted into the rack 342. place; the inside of the fan-shaped obstacle-crossing box 343 is provided with an actuating structure 344 near the inner wall, and the actuating structure 344 and the triggering structure 345 are arranged in a signal connection.

[0041] Wherein the triggering structure 345 includes an elastic airbag 3451, an air flow sensor 3452 and an elastic rack 3453. The fan-shaped barrier overcoming box 343 is fixed with an elastic airbag 3451, and the bottom end of the elastic airbag 3451 is connected with an elastic rack 3453, and the elastic rack 3453 is alternately inserted into the At the gap of the rack 342; the top of the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com