Device and method for keeping pallet fork of rotary conveyor horizontal

A rotary conveyor and fork technology, which is applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of large number of balance tracks, troublesome adjustment, poor fork rotation rigidity, etc., to solve the problem of fork rotation The effect of poor positioning, improved fork rotation rigidity, and simple installation and adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

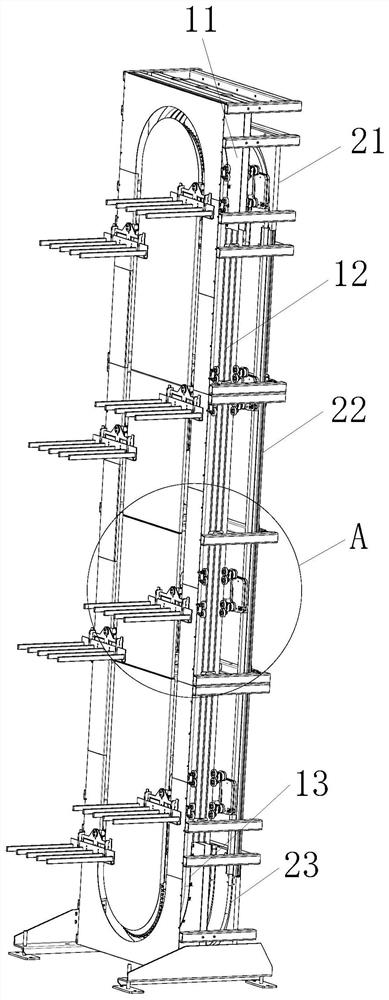

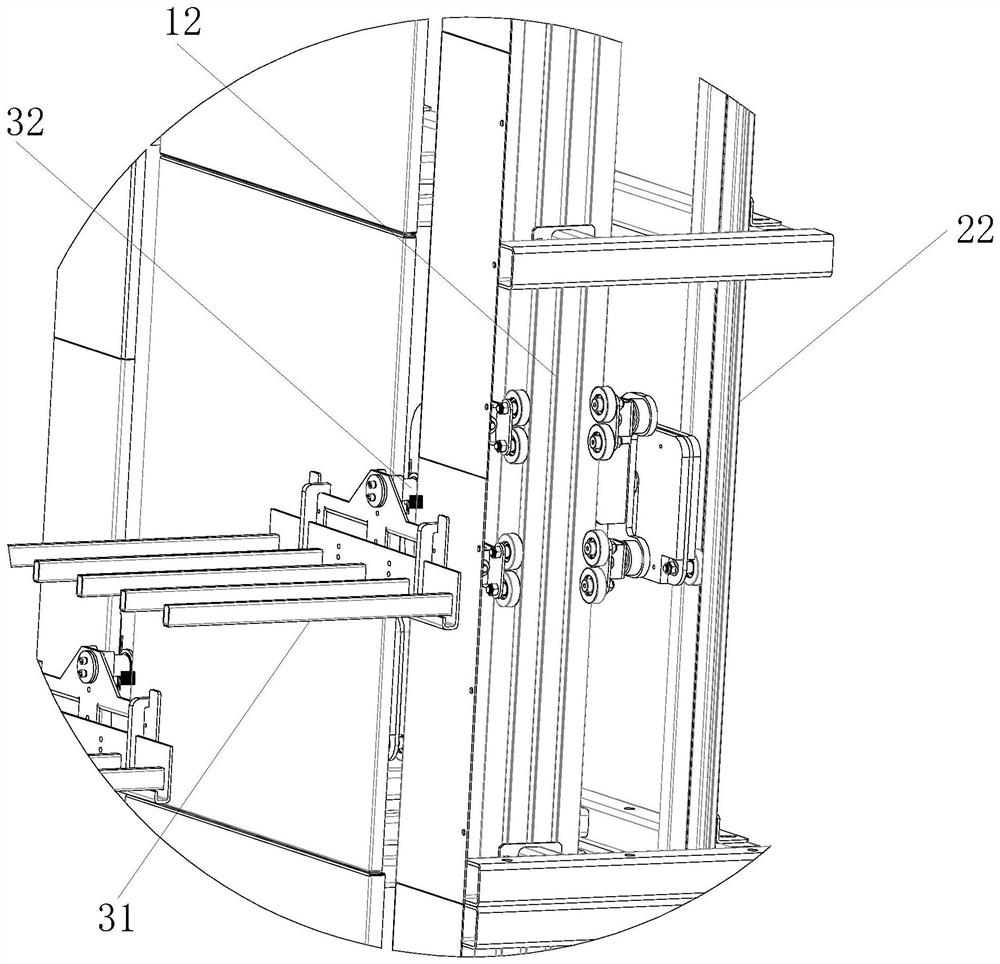

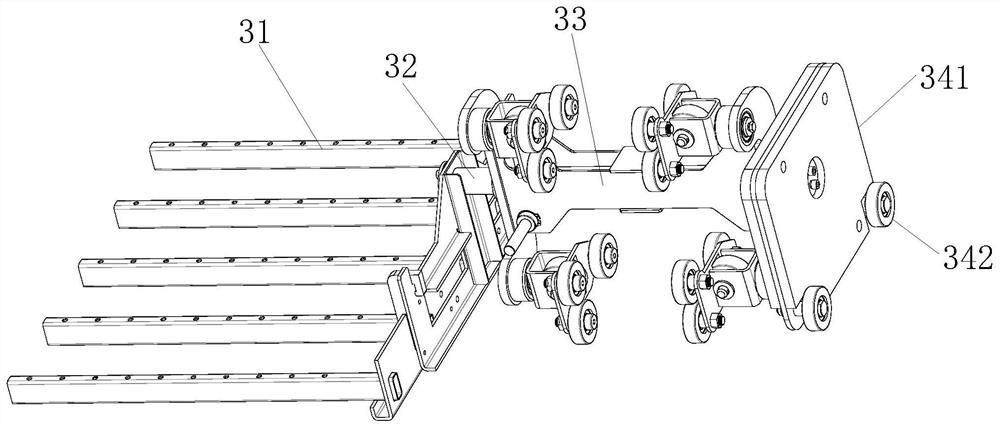

[0024] refer to figure 1 and figure 2 As shown, Embodiment 1 of the present invention provides a device for maintaining the level of the fork on a rotary conveyor, including a main rail, a balance rail and a fork mechanism. The fork mechanism includes a fork 31, a fork shaft 32, a trolley assembly 33 and Balance assembly, one end of the fork shaft 32 is provided with a fork 31, the fork shaft 32 is located in the trolley assembly 33, the trolley assembly 33 is installed on the main track and the trolley assembly 33 drives the fork 31 to walk along the main track; the balance assembly includes Mounting plate 341 and balance wheel 342, the other end of pallet fork shaft 32 is provided with mounting plate 341, and the other side of mounting plate 341 far away from trolley assembly 33 is provided with balance wheel 342, and balance wheel 342 is installed on the balance rail and balance wheel 342 along Balance track walking, the center of rotation of balance wheel 342 and pallet ...

Embodiment 2

[0029] Embodiment 2 of the present invention provides a method for a rotary conveyor to keep the fork 31 horizontal, including:

[0030] Fork 31 is installed on the trolley assembly 33 by fork shaft 32, and trolley assembly 33 is installed on the main rail and can walk along the track on the main rail; Wheel 342 is installed on the balance rail and the balance wheel 342 walks along the balance rail. The center of rotation of the balance wheel 342 and the fork shaft 32 is not coaxial. The shaft 32 swings so that the pallet fork shaft 32 and the pallet fork 31 mounted on the pallet shaft 32 remain horizontal.

[0031] Specifically, the upper balance track 21 and the lower balance track 23 included in the balance track are provided with two track grooves 24, and when two balance wheels 342 pass through the upper balance track 21 or the lower balance track 23, they pass through the two track grooves 24 The two balance wheels 342 are double positioned to limit the rotation of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com