Three-dimensional shape measuring device

A measuring device and technology of three-dimensional shape, applied in the field of three-dimensional shape measuring device, can solve the problems such as weakening of rotational rigidity, weakening of rotational rigidity of Z-axis drive shaft, measurement error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

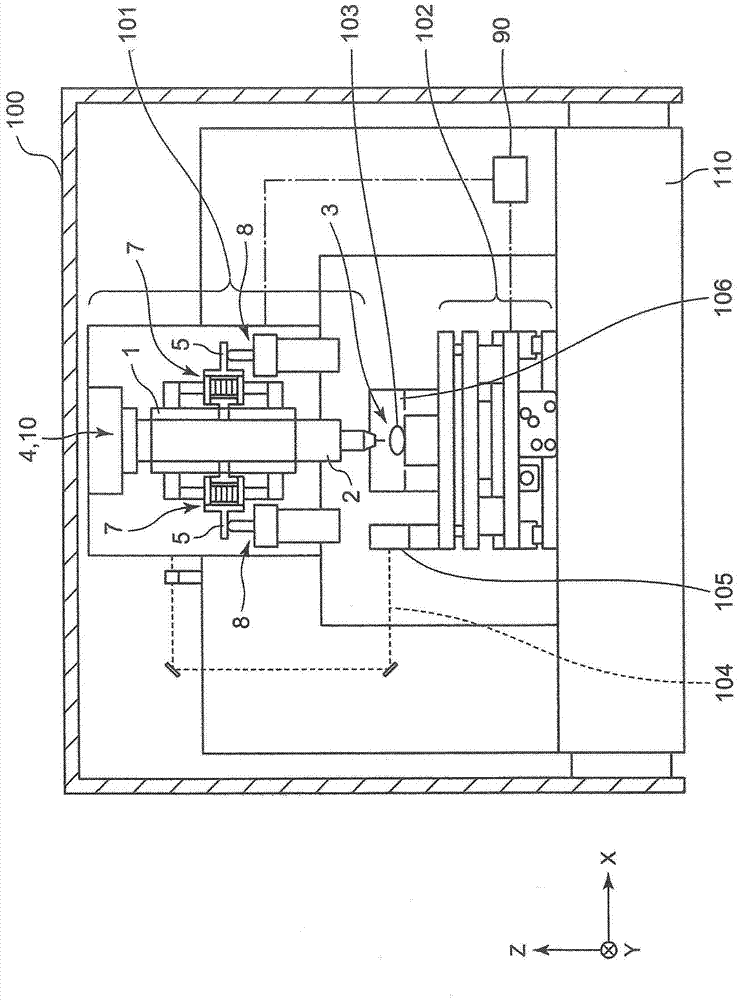

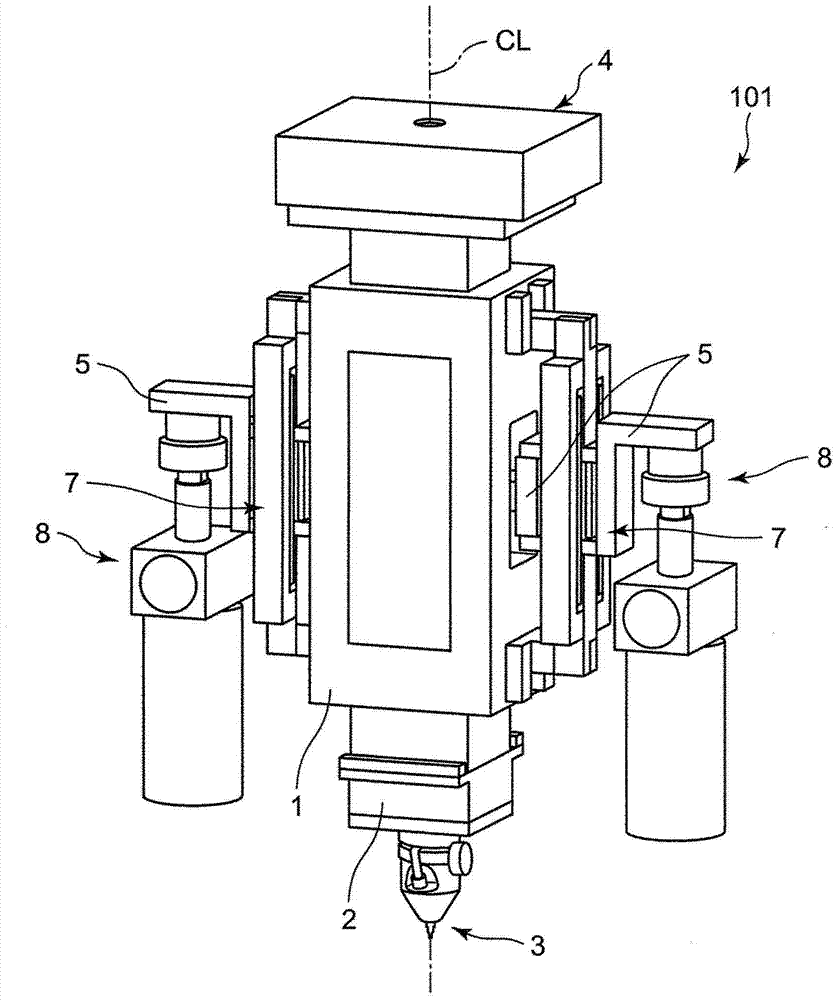

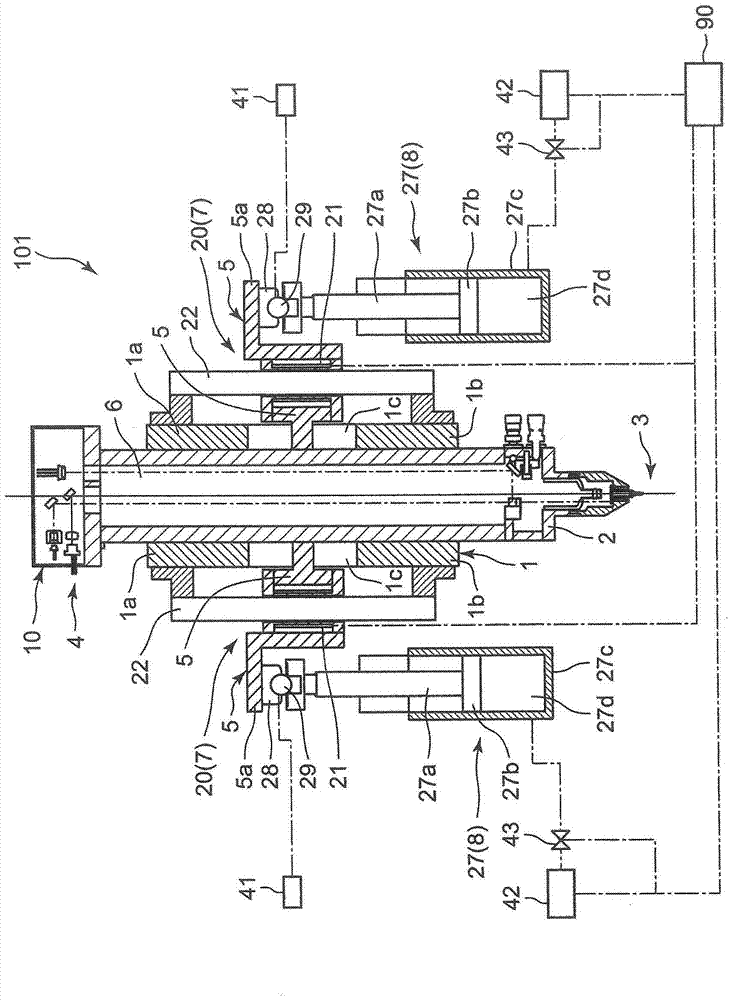

[0050] Hereinafter, the three-dimensional shape measurement device 100 according to the embodiment of the present invention will be described in detail with reference to the drawings. figure 1 The overall structure of the three-dimensional shape measuring device 100 is shown.

[0051] The three-dimensional shape measuring apparatus 100 includes an XY table 102 , a Z-axis table section 101 , and a control section 90 . The XY table 102 is disposed on the platform 110 so as to be movable in the XY axis direction, and the XY table 102 is used to mount and hold the measurement object 103 so that the measurement object 103 can move in the XY axis direction. The Z-axis table part 101 is supported by the platform 110 so as to be able to move along the Z-axis direction, that is, the vertical direction (vertical direction), and supports the detection part 3 which contacts the measurement surface of the measurement object 103 at the lower end, so that the detection part 3 can Moving up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com