Air source heat pump defrosting control point laboratory determination system and method

An air source heat pump and measurement method technology, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as wrong defrosting, and achieve the effects of avoiding wrong defrosting, simple operation, and short test cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

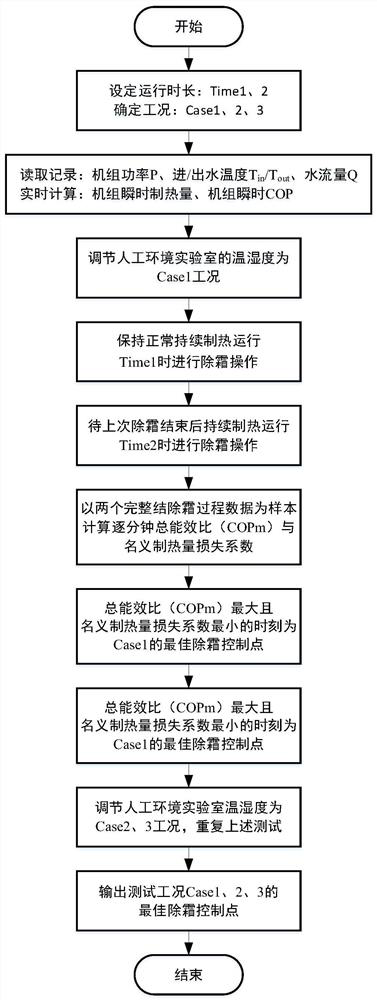

[0049] Below in conjunction with accompanying drawing, do further example description for the present invention:

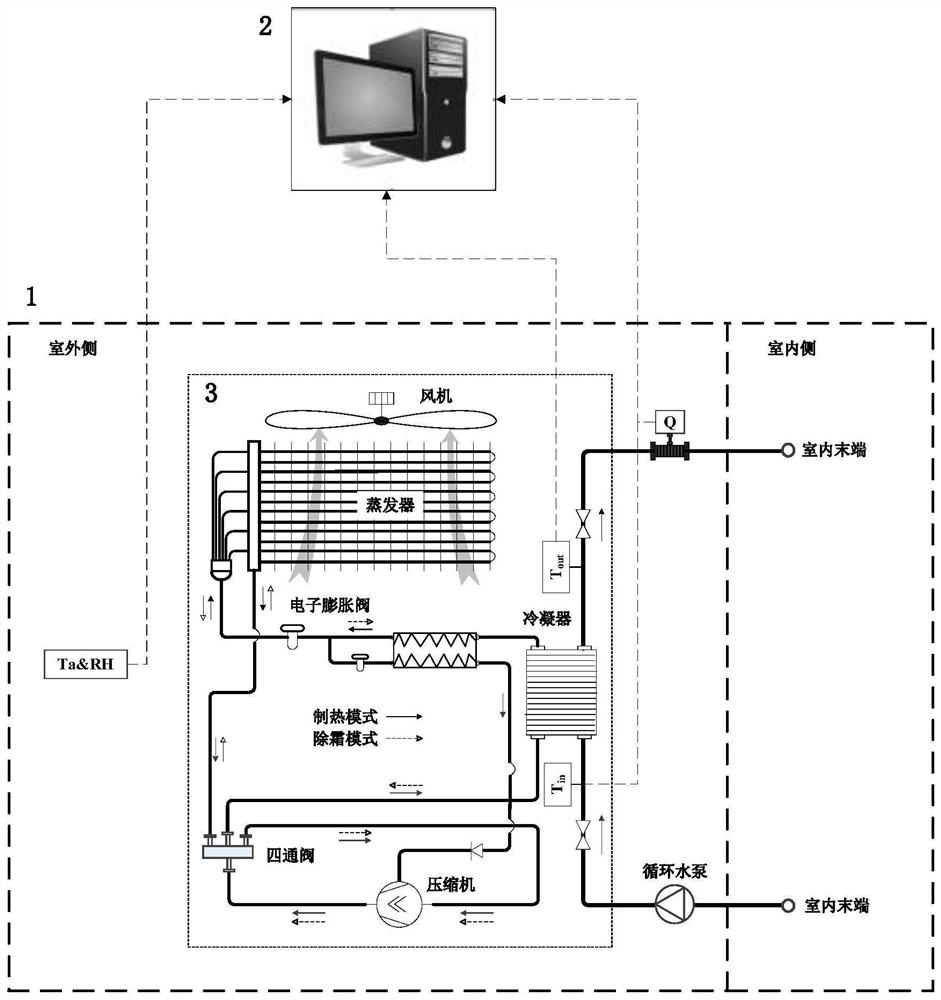

[0050] combine figure 1 , an air source heat pump defrosting control point laboratory measurement system based on the optimal defrosting control point theory of the present invention, including an artificial environment laboratory 1, a real-time data monitoring and recording platform 2, a measured air source heat pump unit 3 and monitoring Several sensor devices.

[0051] Among them, the temperature and humidity sensor monitoring point is set in the outdoor space of the artificial environment laboratory 1 to test the ambient temperature and humidity of the evaporator of the air source heat pump unit 3 under test; Monitor the power consumption P of the unit; install plug-in temperature sensors on the inlet / outlet pipes of the condenser of the air source heat pump unit 3 to be tested, and test the inlet / outlet water temperature T of the unit in / T out Install wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com