A self-cleaning photoelectric frost thickness sensor

A self-cleaning, sensor technology, applied in heat pumps, compressors, damage protection and other directions, can solve the problems of signal failure, control stability cannot be guaranteed, etc., to achieve the effect of strong applicability, self-cleaning, and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

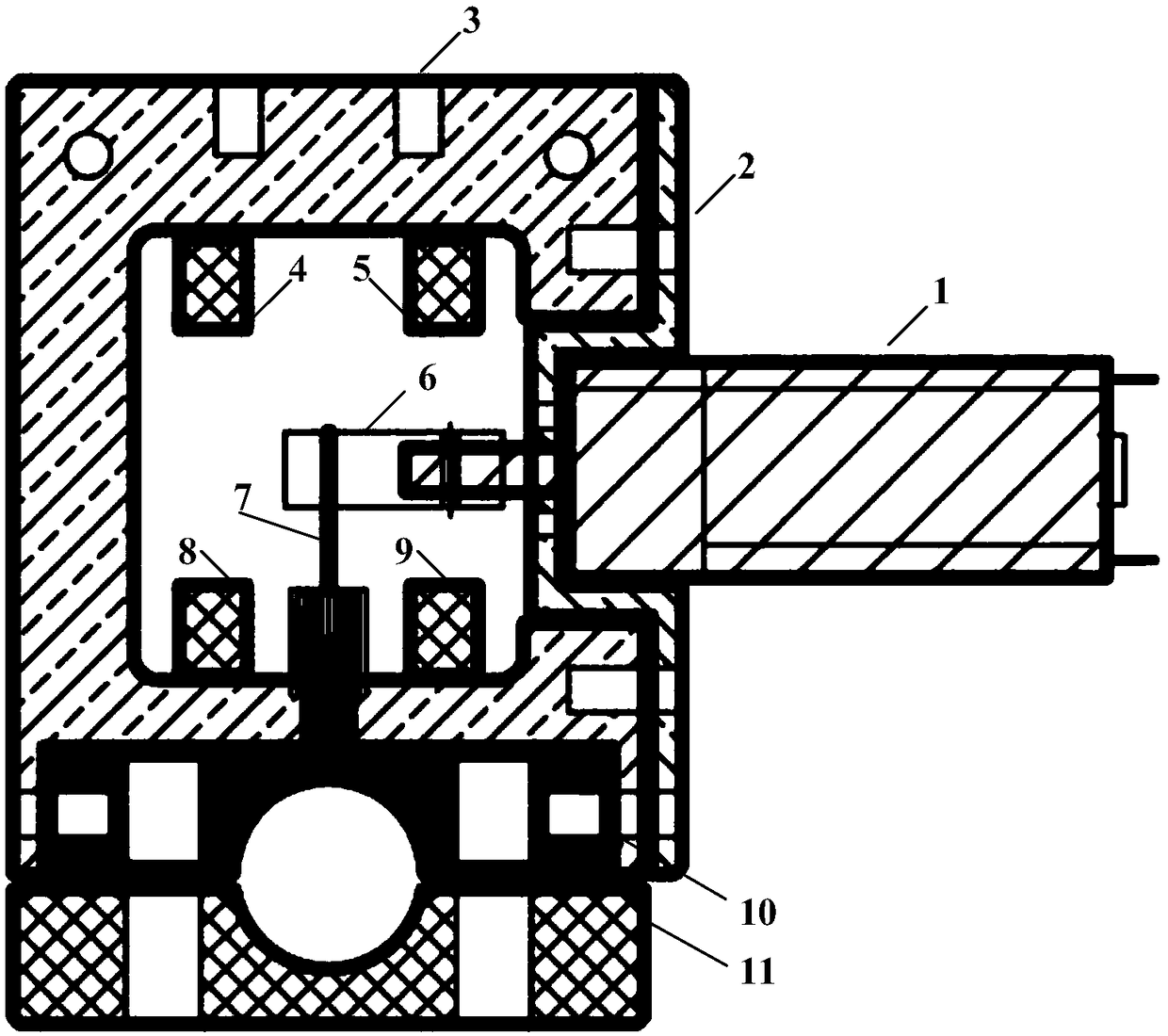

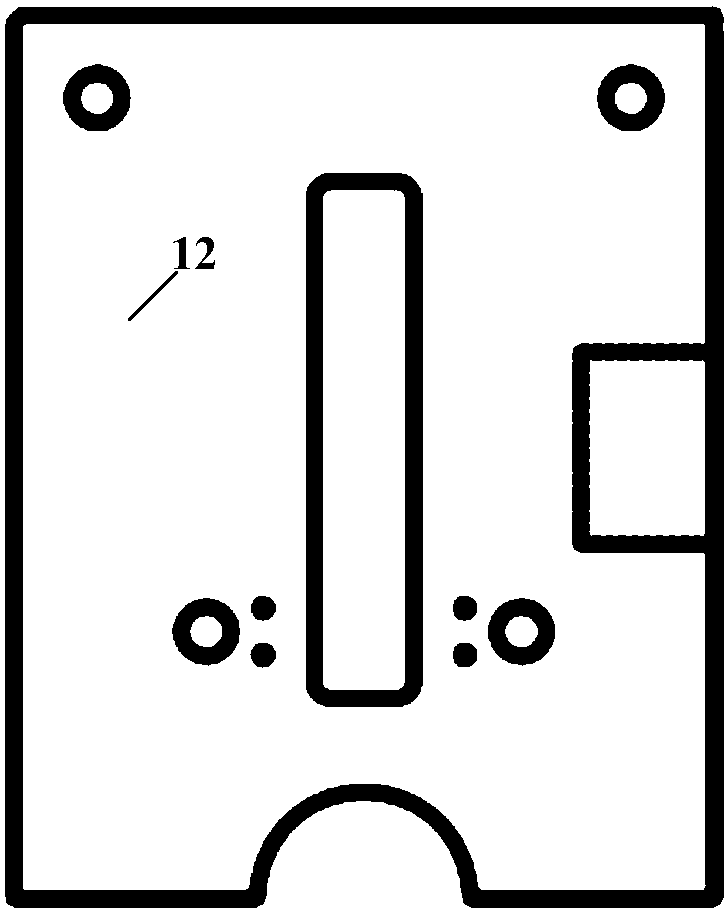

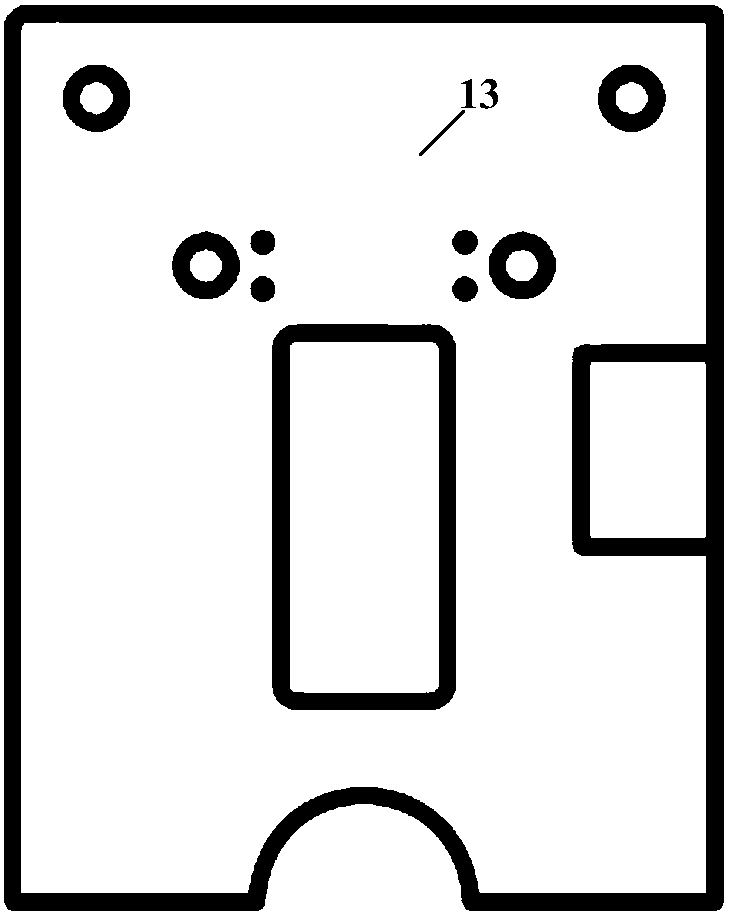

[0016] Depend on Figure 1~4 It can be seen from the illustrated embodiment of the present invention that the self-cleaning photoelectric frost thickness sensor mainly includes a geared motor 1, a motor fixing part 2, a connecting body 3, a positioning light transmitter 4, a positioning light receiver 5, a shaft sleeve 6, and a brush 7. Frost measuring light transmitter 8 , frost measuring light receiver 9 , heat conducting element 10 , sensor fixing element 11 , front cover 12 , rear cover 13 and top cover 14 .

[0017] Wherein, the geared motor 1 is fixed together with the connecting body 3 through the motor fixing member 2, and the connecting body 3 is made of heat-insulating and insulating material, such as nylon and bakelite can be selected. Hairbrush 7 is connected together with reduction motor 1 rotating shaft by axle sleeve 6, and hairbrush material should be soft, wear-resistant. The heat conduction element 10 is nested in the groove of the connection body 3, the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com