An Internet sensor connector

A technology of sensors and connectors, which is applied in the field of Internet sensor connectors, can solve problems such as damage to sensor connectors, communication interruptions, and adverse effects of connected equipment, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

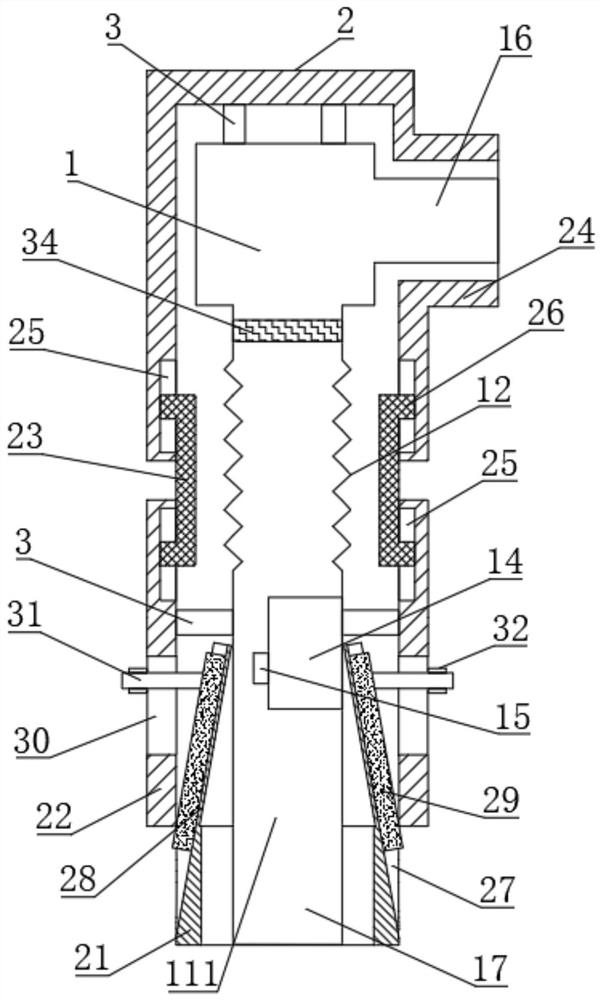

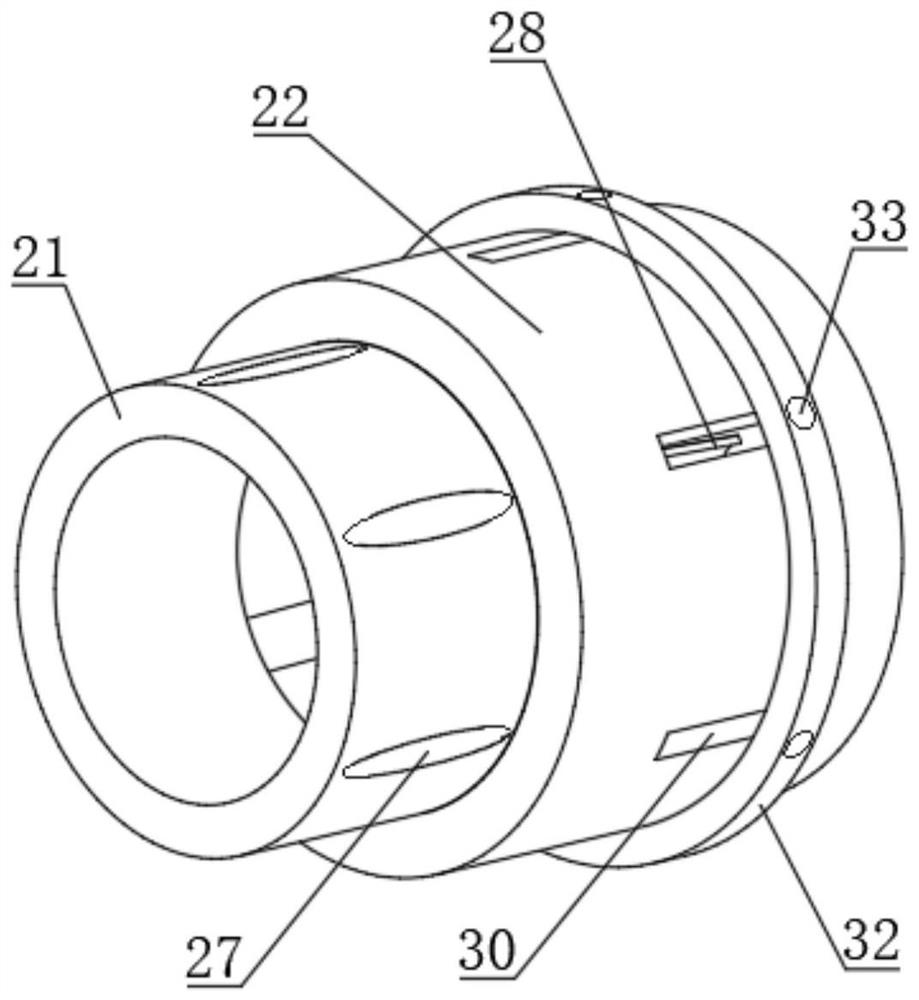

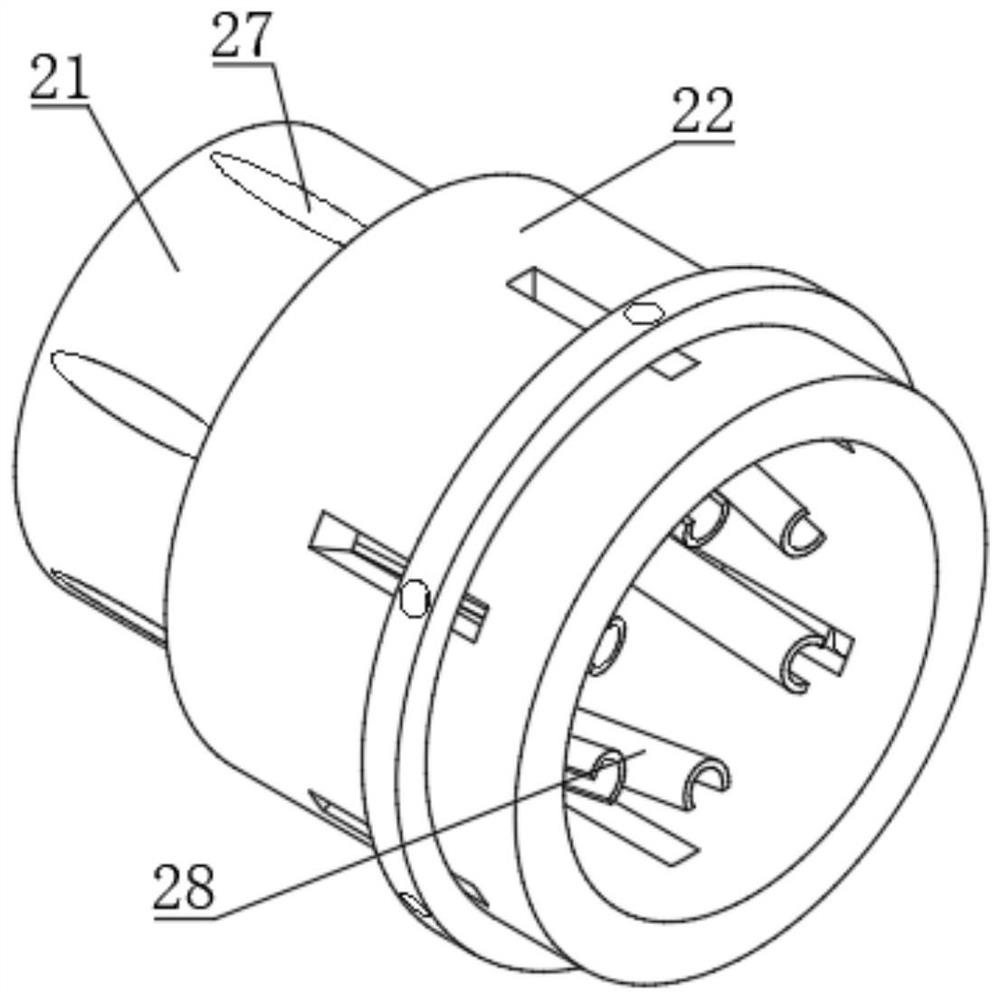

[0028] see Figure 1 to Figure 5 , an Internet sensor connection head, including a joint body 1 and an insulating shell 2, the inside of the joint body 1 is provided with a current converter 14, and the upper end and the lower end of the joint body 1 are respectively provided with a first interface 16 and a second interface 17 , the insulating shell 2 is sleeved on the outside of the joint body 1, the insulating shell 2 is composed of a fastening shell 21, a lower shell 22, a transition shell 23 and an upper shell 24, and the fastening shell 21 is set on the second On the outside of the second interface 17, the upper end surface of the fastening casing 21 is fixedly connected with the lower end surface of the lower casing 22. Several oblique through holes 27 are arranged on the outer surface of the fastening casing 21, and the oblique through holes 27 One end of one end is fixedly connected with an oblique arc guide plate 28, and the oblique arc guide plate 28 is located insid...

Embodiment 2

[0035] see Figure 1 to Figure 5 , this embodiment is a further description of the Internet sensor connector described in Example 1. In this embodiment, the inner surface at the upper end of the lower casing 22 and the inner surface at the lower end of the upper casing 24 are both An annular limiting groove 25 is provided, and an annular limiting block 26 is provided at the upper end and the lower end of the transition casing 23, and the outer surface of the annular limiting block 26 is slidably matched with the inner side wall of the annular limiting groove 25 connection, the inner diameter value of the lower casing 22 is the same as the inner diameter value of the upper casing 24, and the inner diameter value of the upper casing 24 is the same as the outer diameter value of the transition casing 23, so that the lower casing 22 and the upper casing The distance between 24 can be changed.

[0036] The joint main body 1 is composed of a lower main body 111, a middle main body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com