Patents

Literature

34results about How to "Implement auto-correction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Data processing method and system for nuclear power plant databases

InactiveCN105653696ALow application costImplement auto-correctionData processing applicationsDatabase distribution/replicationData warehouseNuclear power

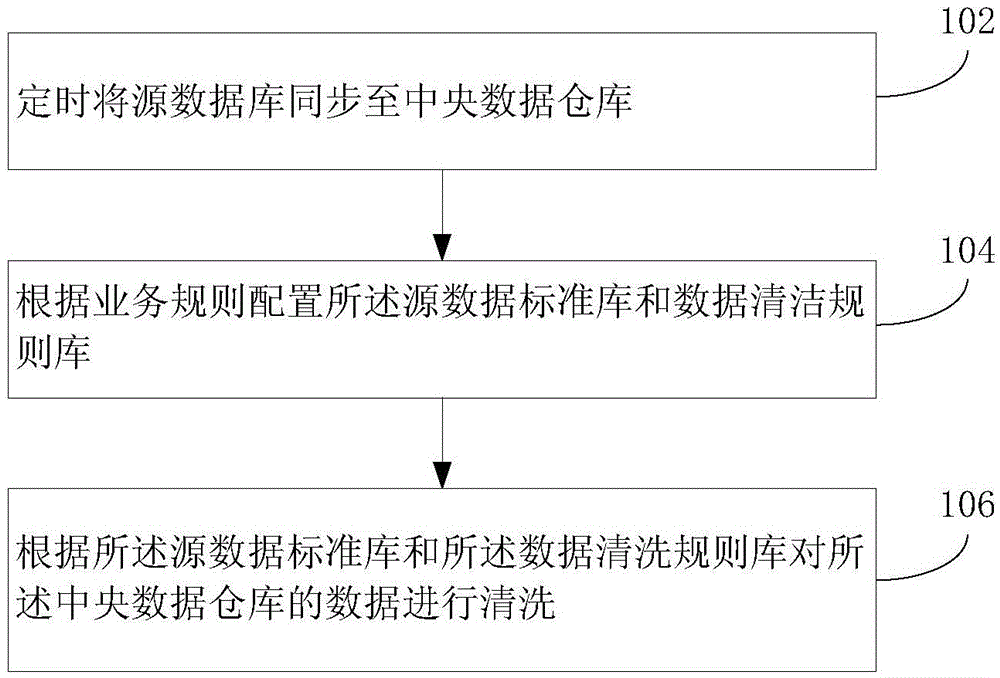

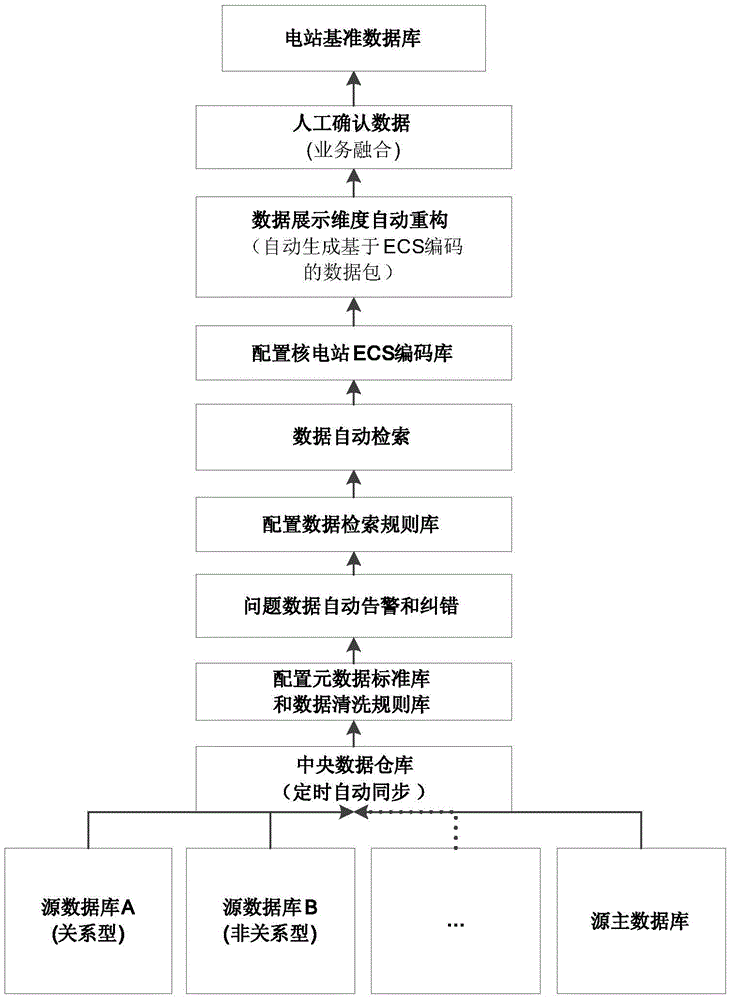

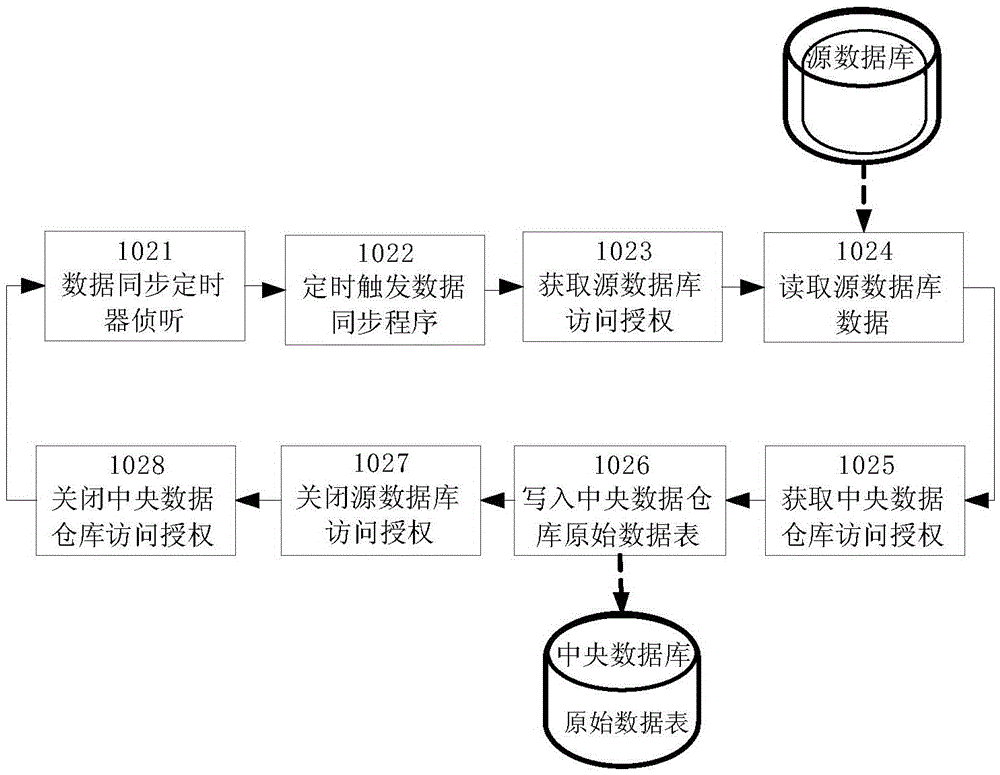

The invention discloses a data processing method for nuclear power plant databases. The method comprises the steps of periodically synchronizing a source database to a central data warehouse; configuring a source data standard library and a data cleaning rule library according to a service rule; and cleaning data of the central data warehouse according to the source data standard library and the data cleaning rule library. The invention further discloses a data processing system for nuclear power plant databases. In specific embodiment, the source database is periodically synchronized to the central data warehouse, the source data standard library and the data cleaning rule library are configured according to the service rule, and the data of the central data warehouse are cleaned, so that data issues of large projects of nuclear power plants and the like are automatically corrected, the data acquisition quality and efficiency of service personnel are improved, the human input to data combing is greatly reduced, the data application cost is effectively reduced, and good economic benefits are produced.

Owner:TAISHAN NUCLEAR POWER JOINT VENTURE +1

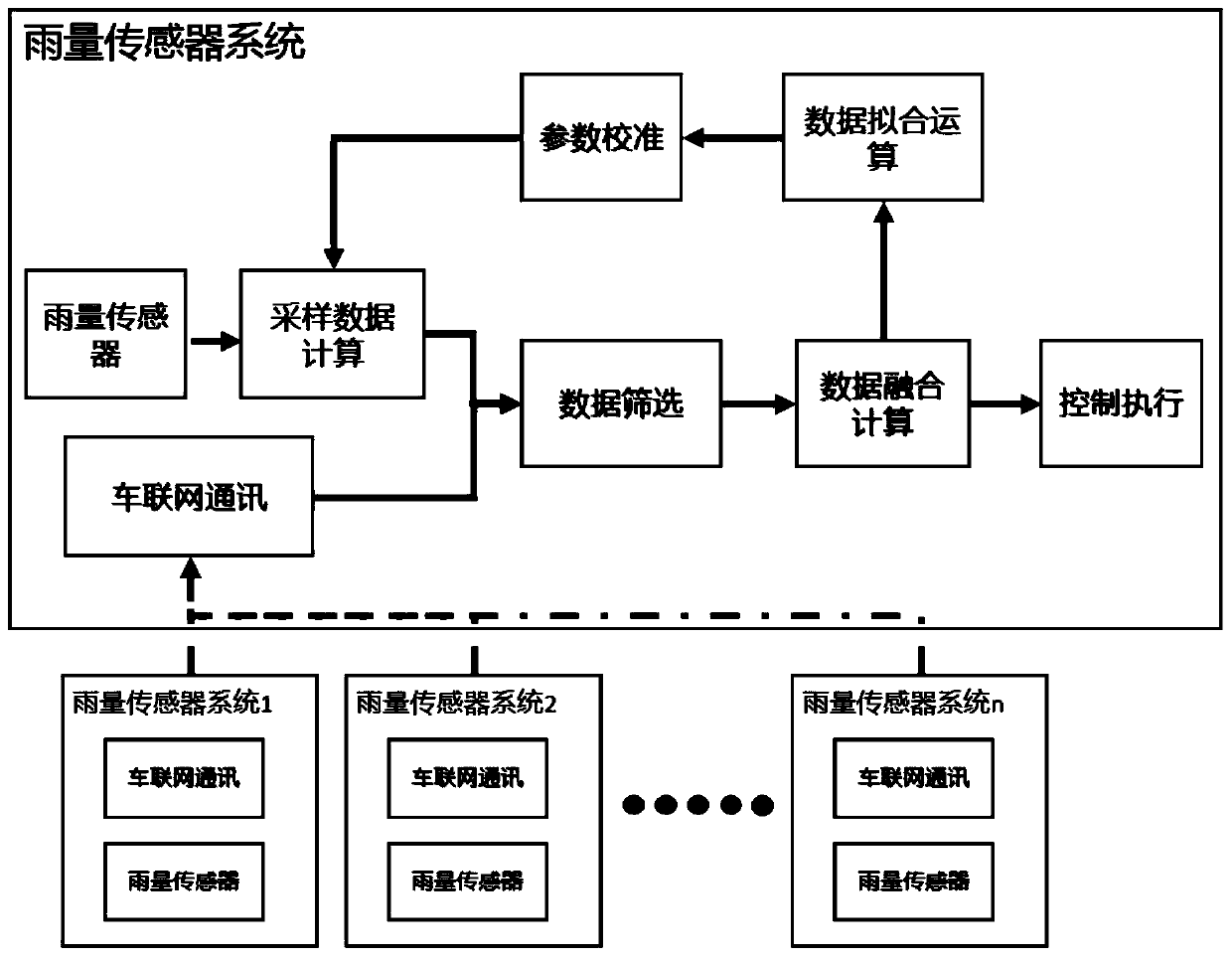

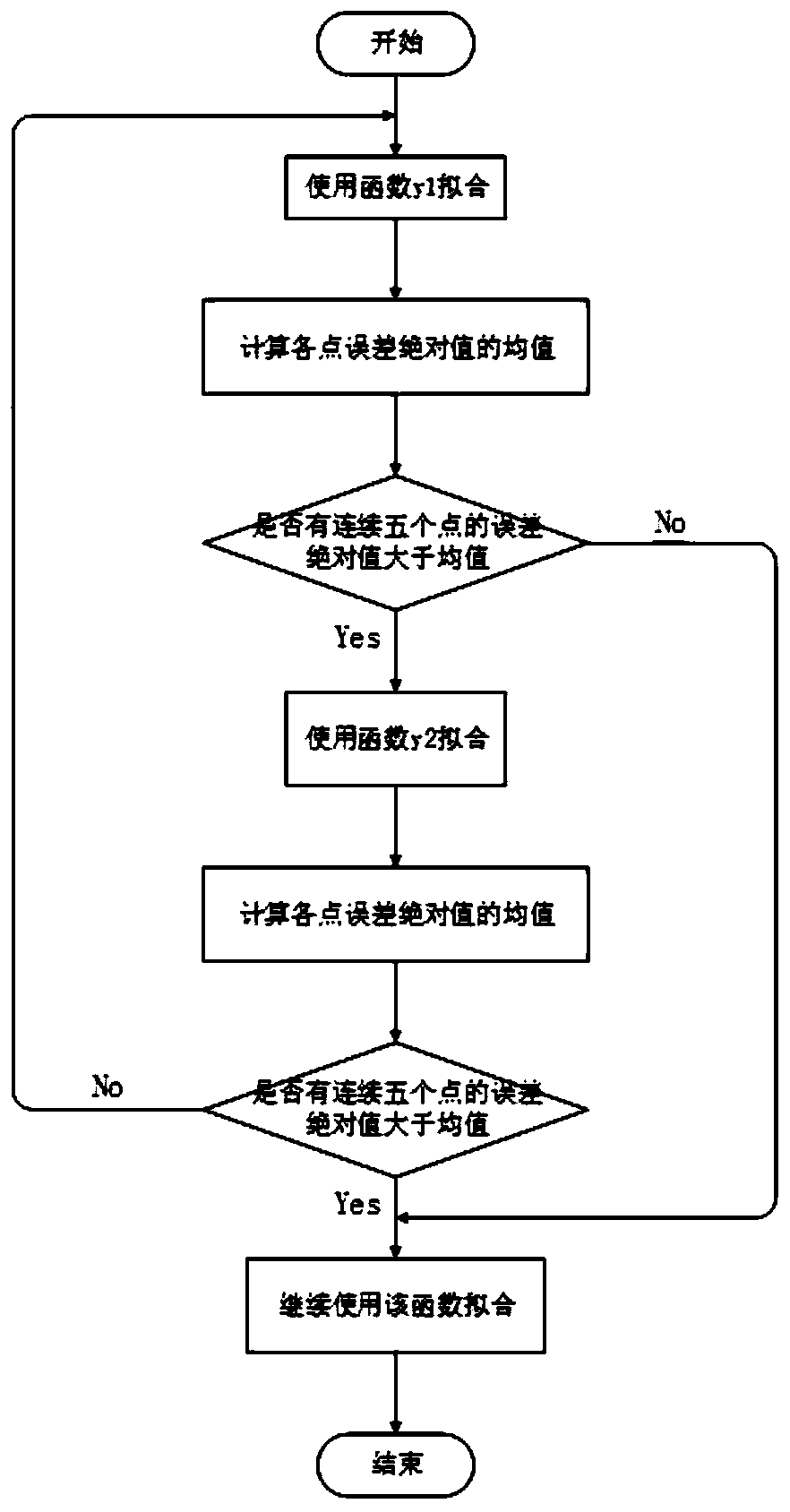

Method and system for automatically calibrating rainfall sensor of vehicle as well as vehicle

InactiveCN109975894AGuaranteed accuracyReduce mistakesRainfall/precipitation gaugesVehicle cleaningEngineeringComputer module

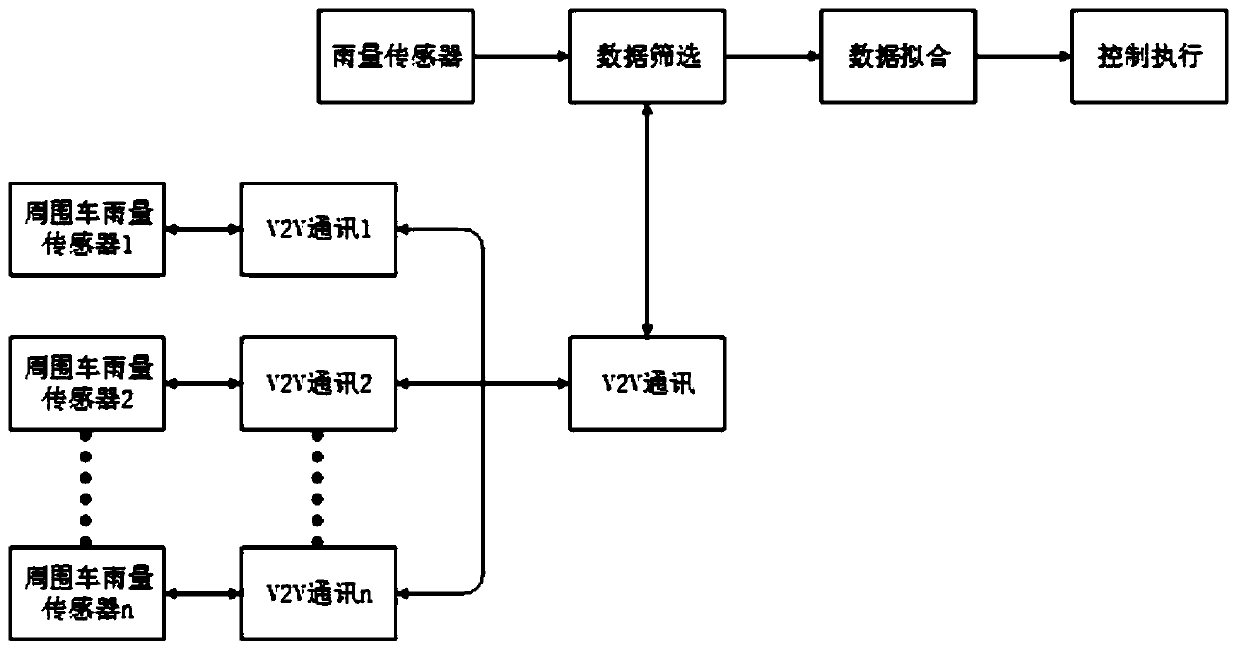

The invention relates to a method and system for automatically calibrating a rainfall sensor of a vehicle based on a vehicular networking communication technology as well as a vehicle. The method comprises the steps of firstly sharing data of the rainfall sensor by virtue of the vehicular networking communication technology and then performing fusion calculation on the data of the rainfall sensorof the vehicle and data of rainfall sensors of vehicles around to obtain an optimal value, so that normal execution of functions of the rainfall sensor of the vehicle is guaranteed and the functions still can be normally realized even if the sensor is in fault. The system comprises the rainfall sensor of the vehicle, a data sharing module, a data screening calculation module, a data fitting moduleand a control and execution module. The method provided by the invention obtains multiple groups of optimal values by performing the fusion calculation on data of multiple rainfall sensors and then performs fitting operation, so that operation parameters of the rainfall sensor of the vehicle are calibrated, an error of the rainfall sensor of the vehicle is reduced and the probability of occurrence of misinformation and failure in report is effectively reduced.

Owner:孙开兴

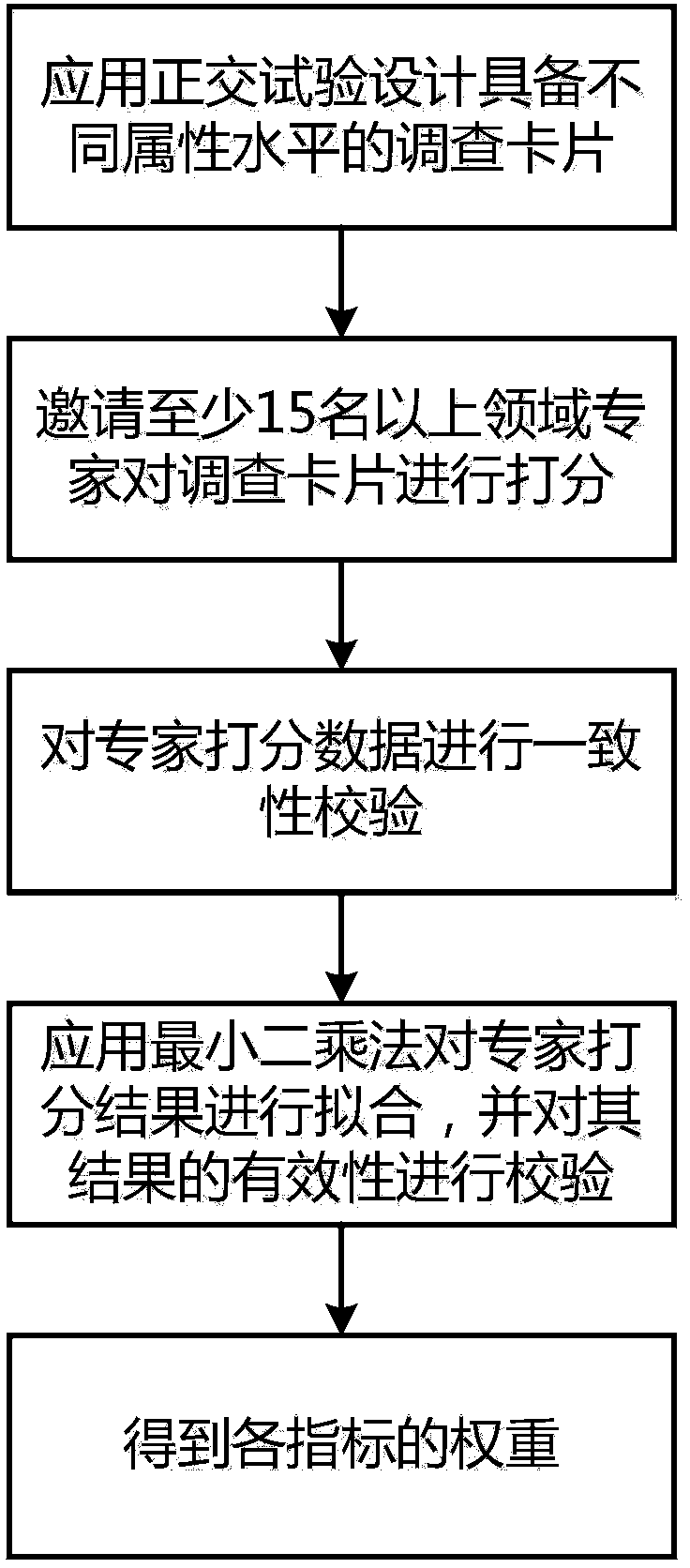

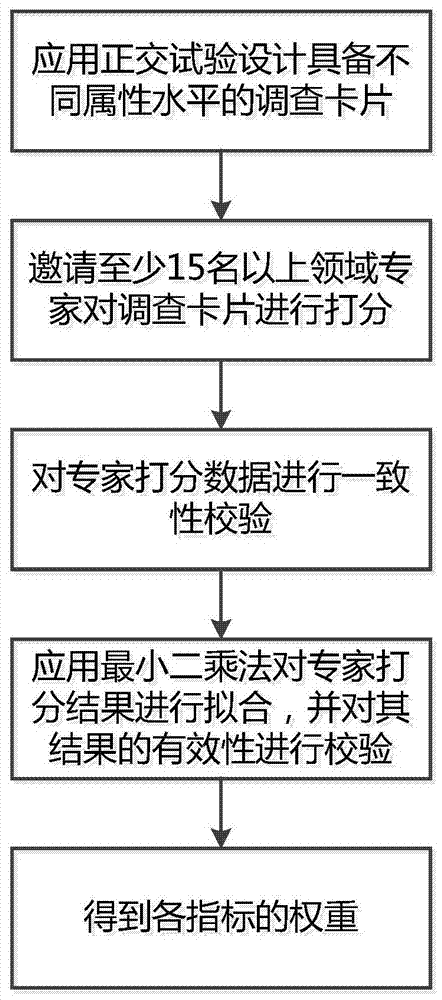

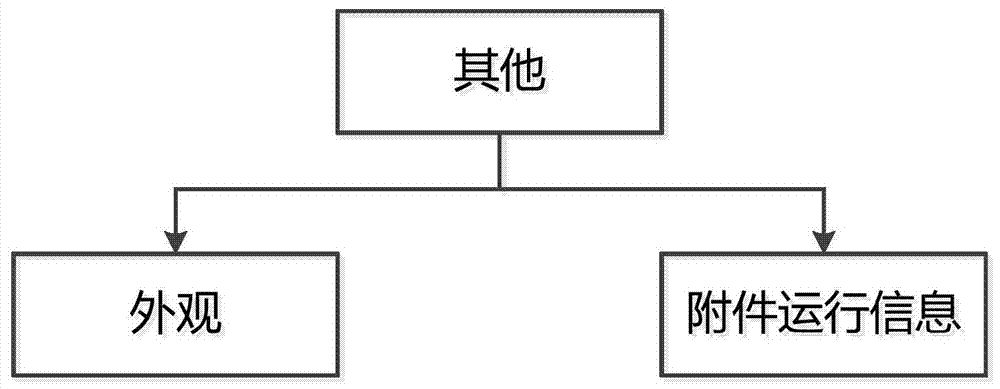

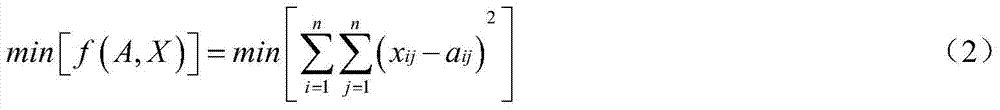

Distribution network device status indicator weight analysis method based on conjoint analysis

ActiveCN104182583AImplement auto-correctionReduce in quantityData processing applicationsSpecial data processing applicationsDevice statusConjoint analysis

The invention provides a distribution network device status indicator weight analysis method based on conjoint analysis. The method includes the steps: 1, survey cards for a distribution network device status indicator are determined by an orthogonal test; 2, the survey cards are scored; 3, uniformity of scoring data is checked; 4, the scoring data with uniformity is fitted by a least square method, validity of the scoring data is checked so as to obtain distribution network device status indicator weight. Compared with the prior art, the method has the advantages that fewer survey cards are used without affecting implementation effect of the conjoint analysis, and the data of the survey cards are subjected to uniformity checking and adjustment.

Owner:STATE GRID CORP OF CHINA +2

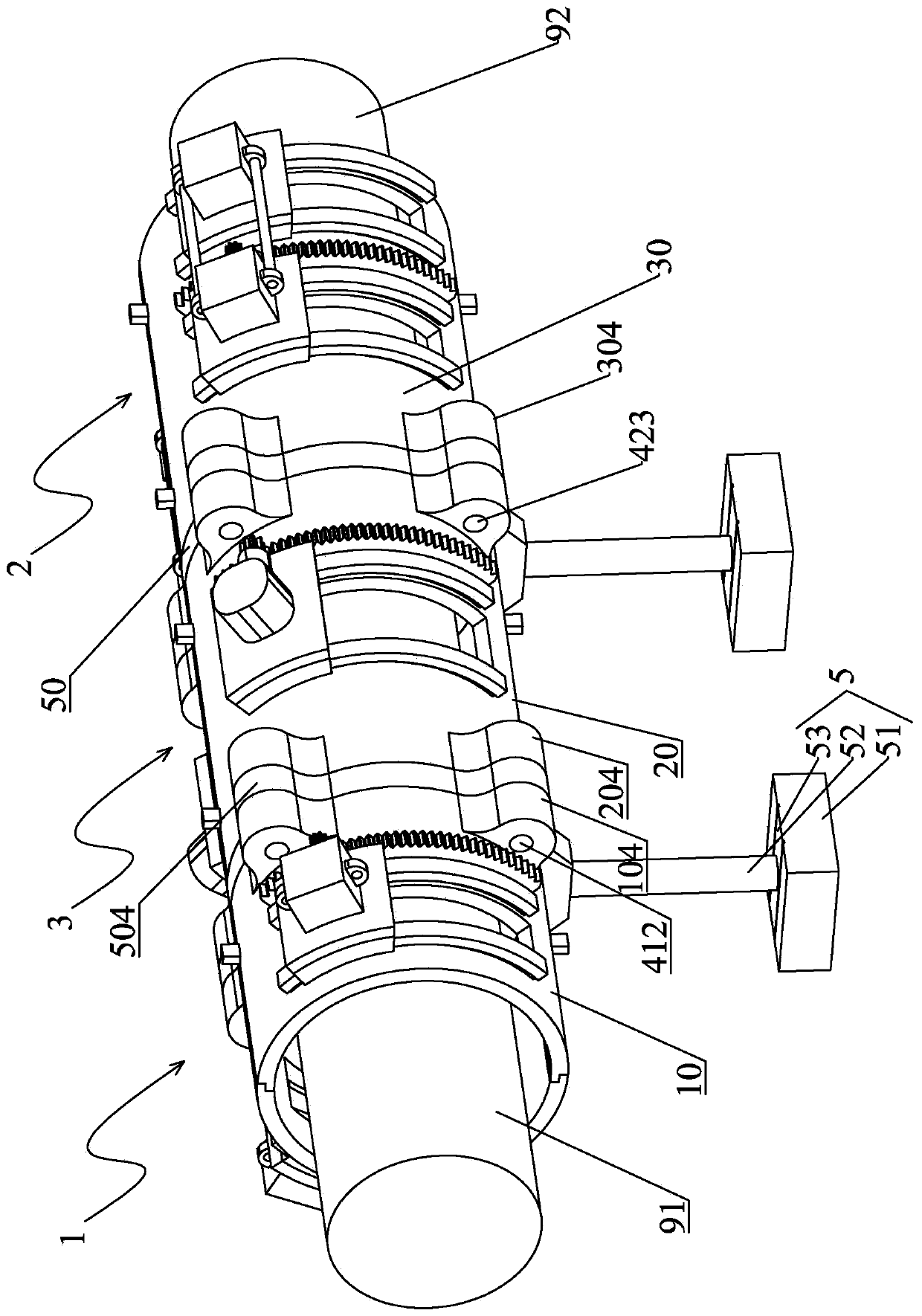

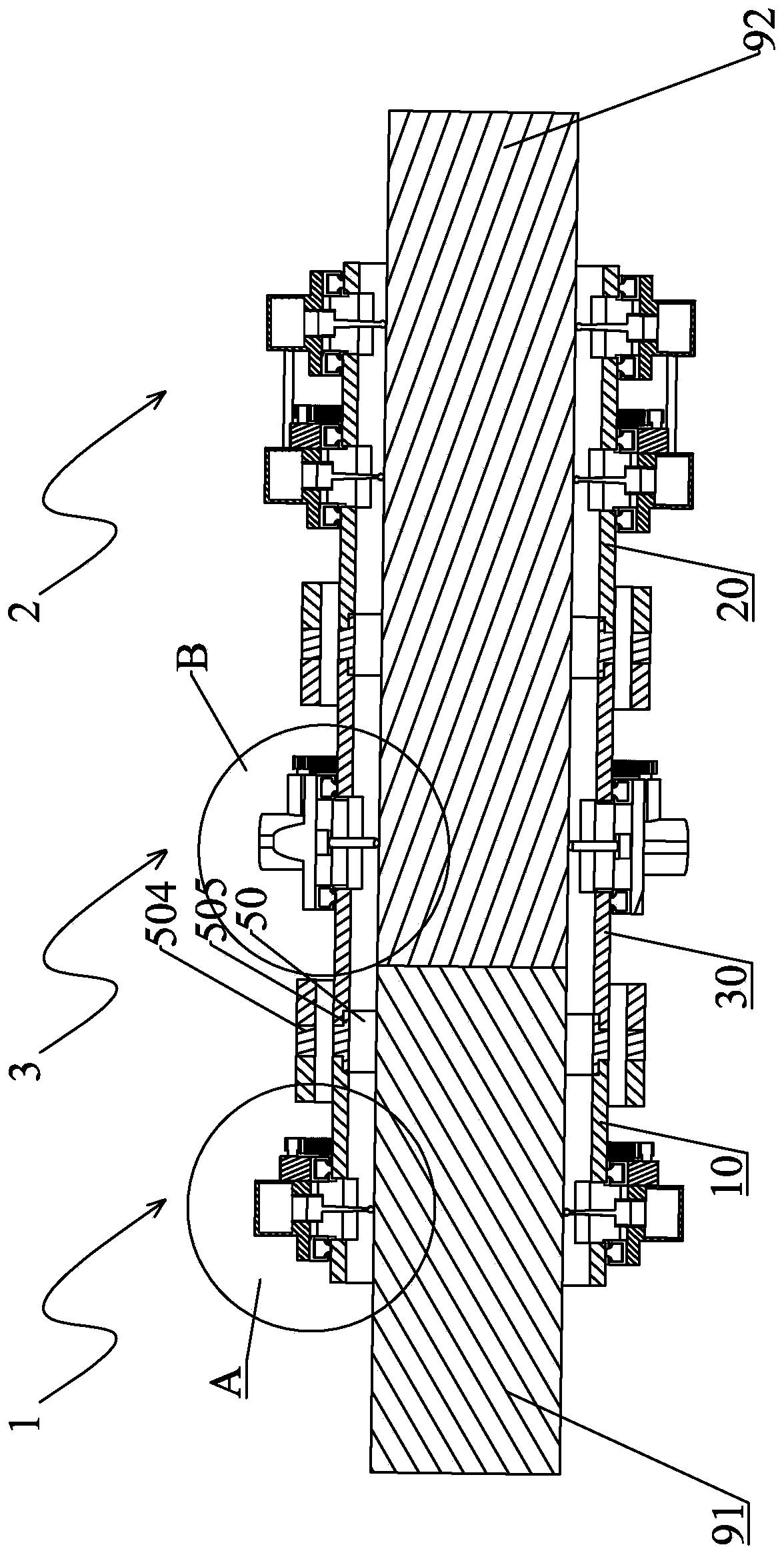

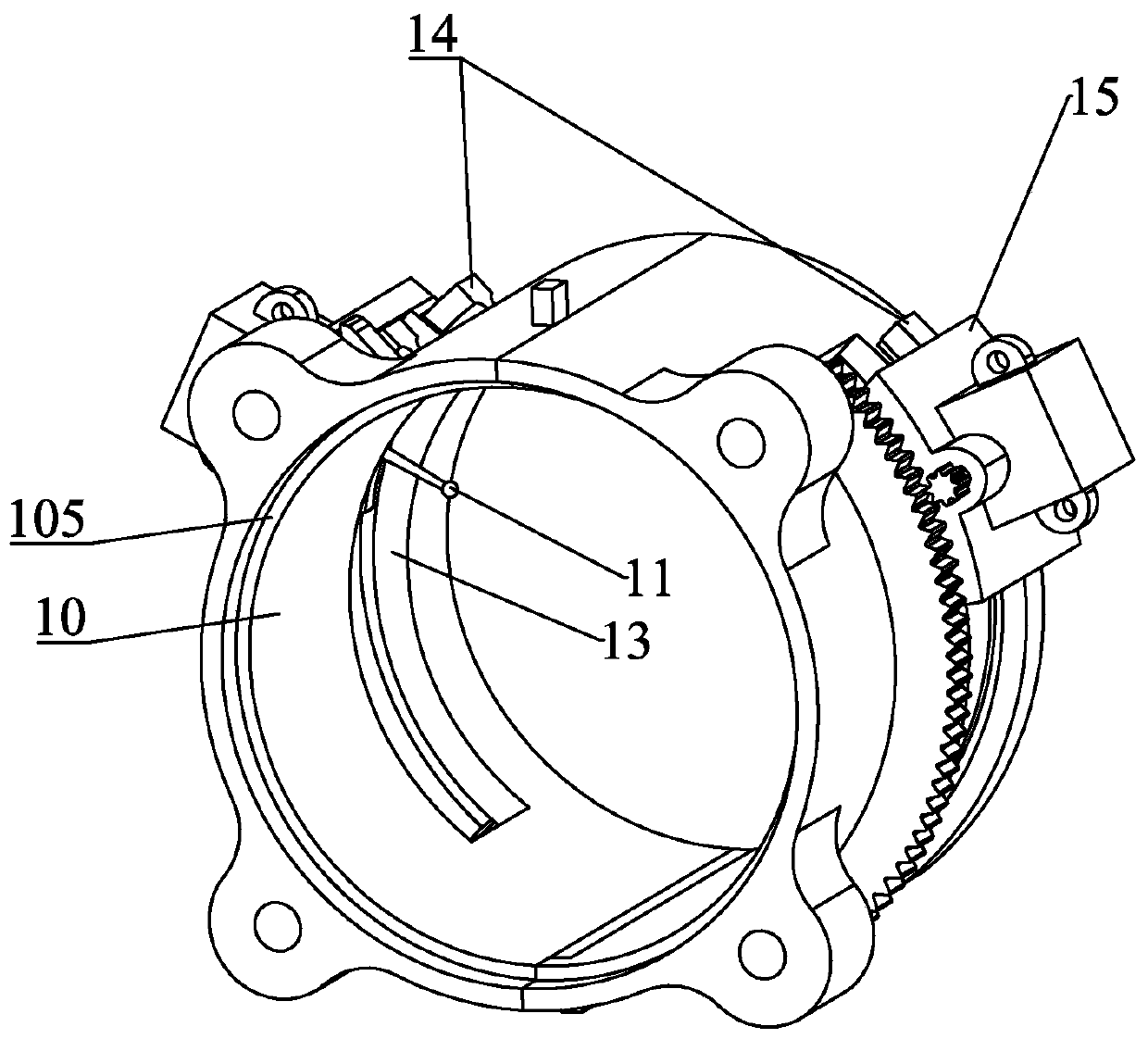

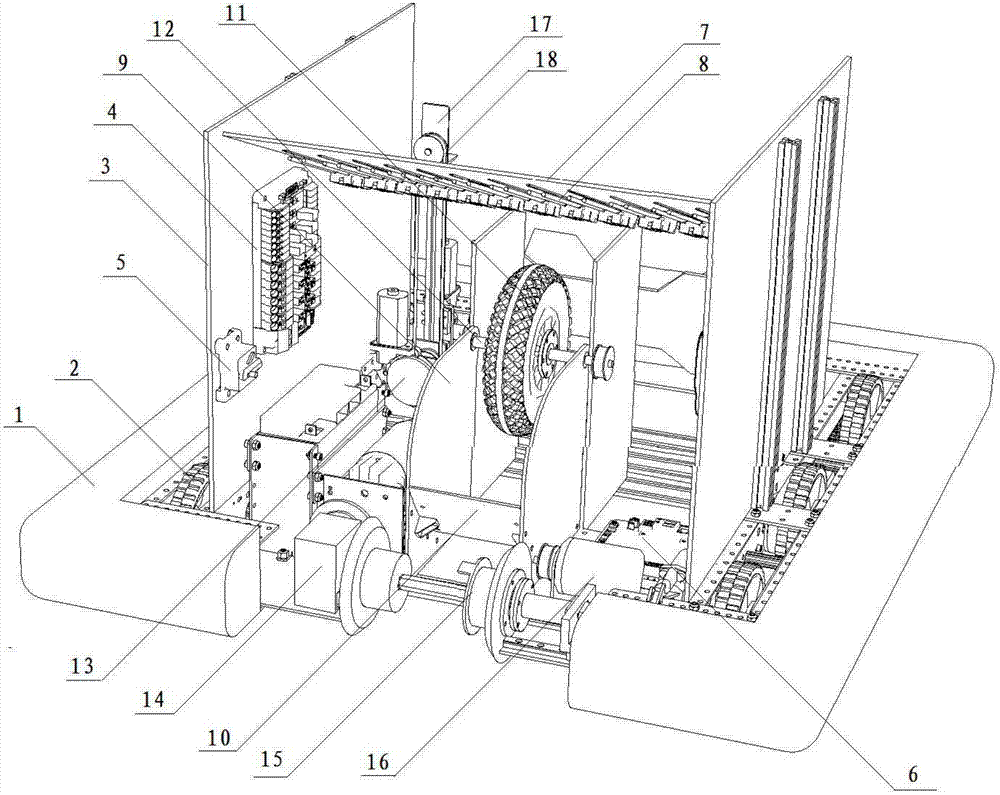

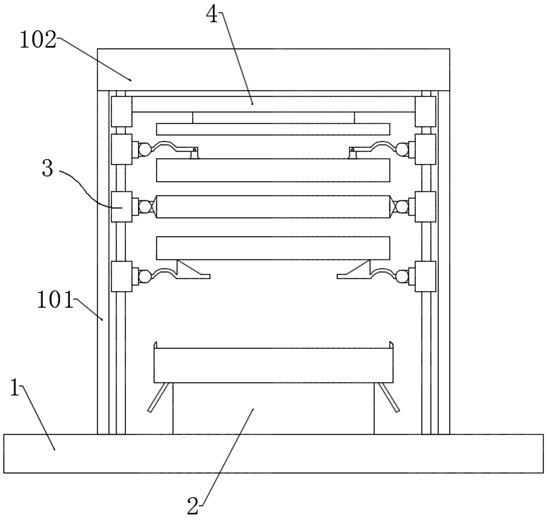

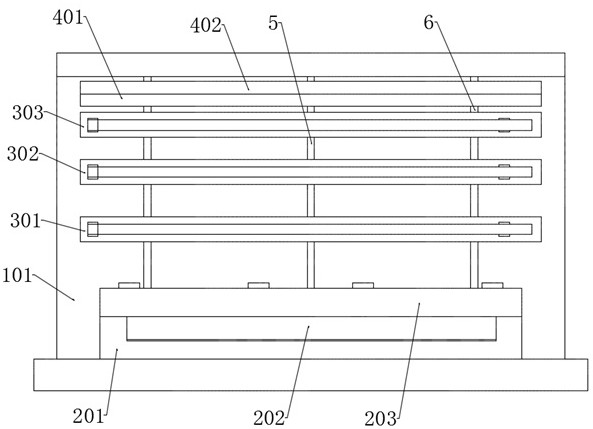

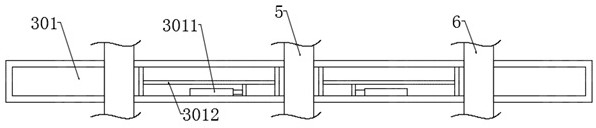

Precision shaft butt joint equipment and precision shaft butt joint method

InactiveCN111113018AImplement auto-correctionPrecise dockingMeasurement devicesMetal working apparatusButt jointControl theory

The invention discloses precision shaft butt joint equipment. The precision shaft butt joint equipment comprises an aligning portion sleeving a first shaft, a detecting portion and a correcting portion, wherein the detecting portion and the correcting portion sleeve a second shaft. The aligning portion, the detecting portion and the correcting portion are coaxially distributed and fixedly connected, sensing devices for acquiring surface radian information of the first shaft and the second shaft correspondingly are mounted on the aligning portion and the detecting portion correspondingly, the sensing device on the detecting portion acquires at least two sets of radian information at different positions of the surface of the second shaft in order to determine radial and axial deviations of the first shaft and the second shaft, and a force applying device for beating the surface of the second shaft to correct the deviations is arranged on the correcting portion. The precision shaft butt joint method includes the steps that the aligning portion and the detecting portion are used for acquiring the deviations between the two shafts, the correcting portion is used for correcting the deviations, and precision shaft butt joint between the first shaft and the second shaft is achieved. A double-section detection method is adopted, the axial and radial deviations between the two shafts tobe subjected to butt joint can be directly acquired, and then two-way precision butt joint between the two shafts is directly achieved.

Owner:XIAMEN UNIV OF TECH

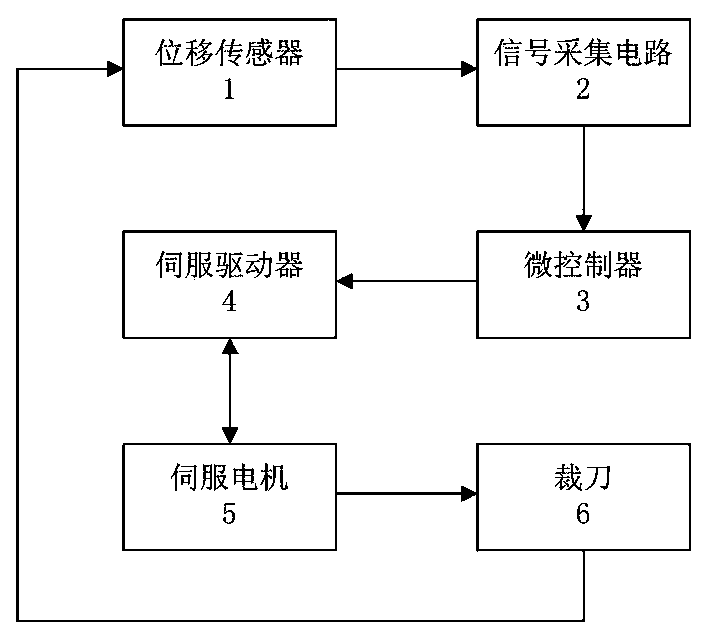

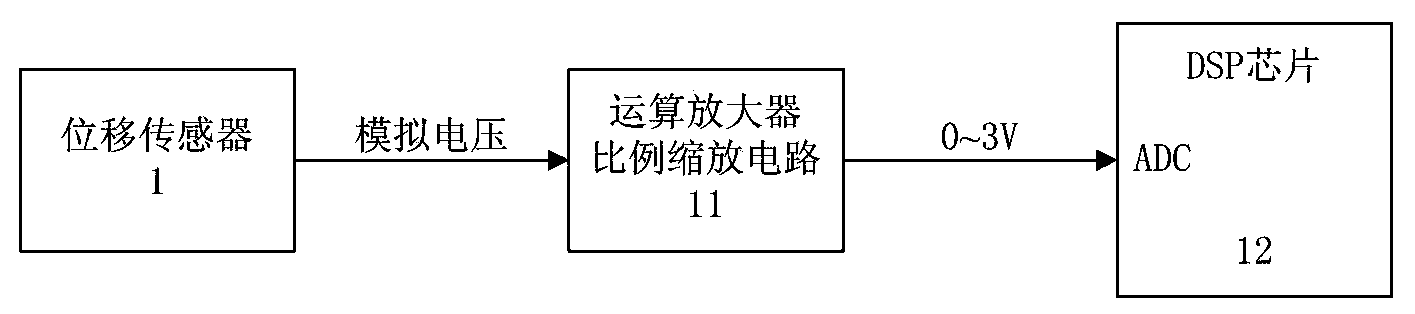

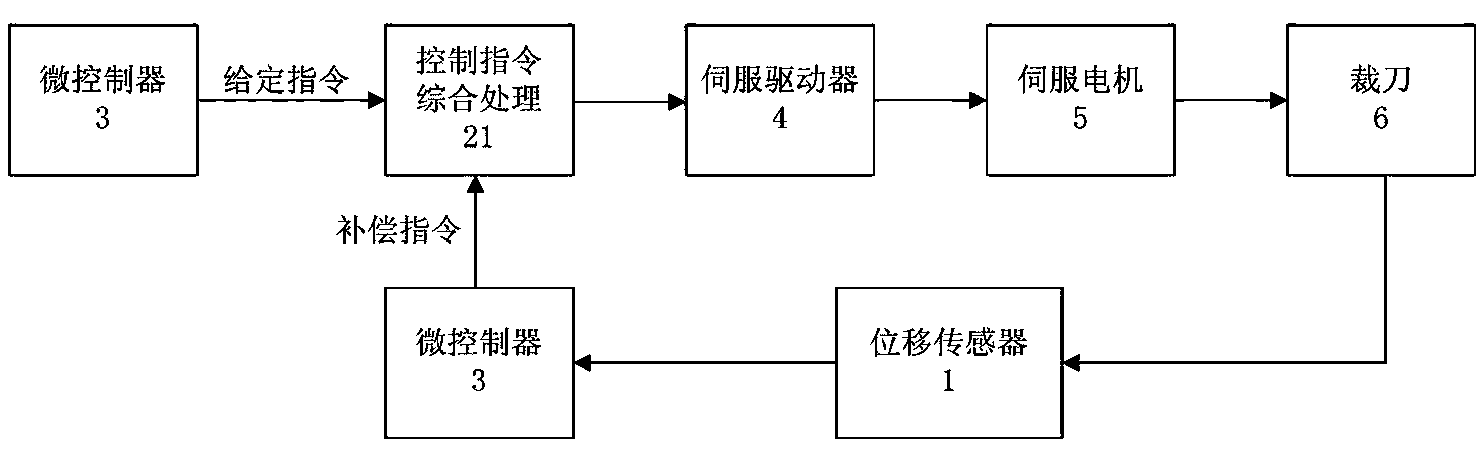

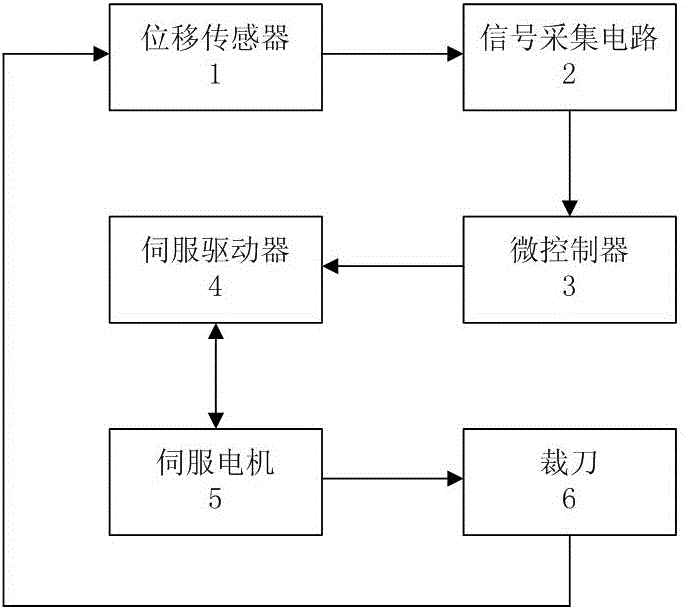

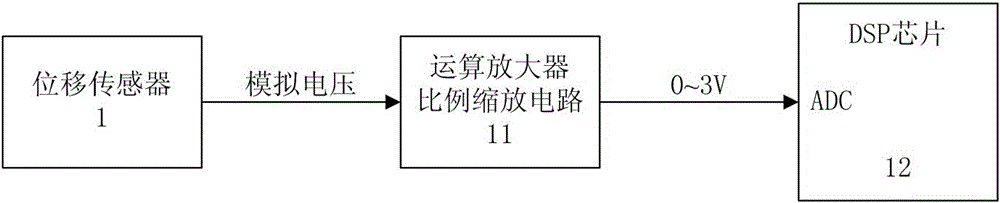

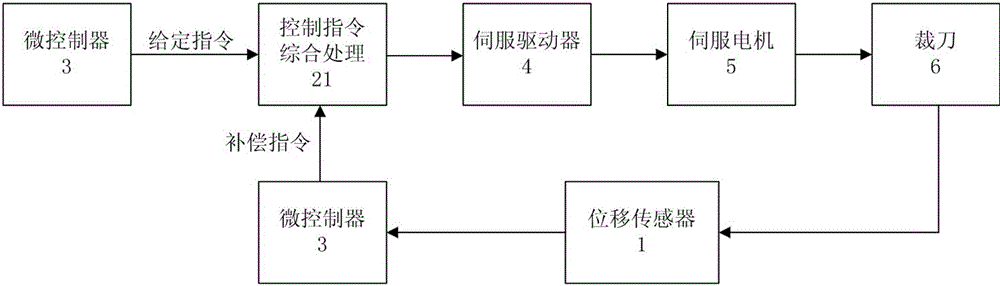

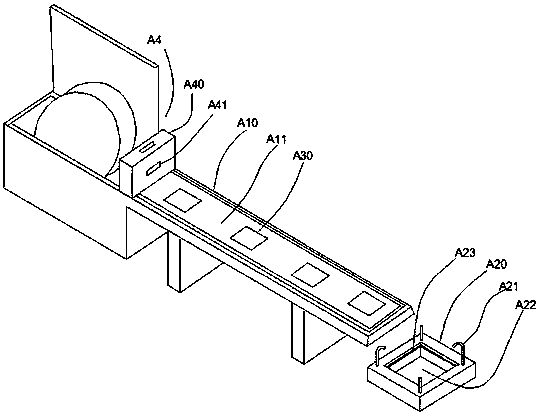

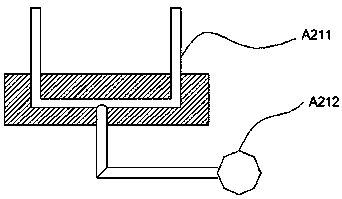

Automatic cutting bed cutter deformation detection device

ActiveCN103776360AImplement auto-correctionProgramme controlComputer controlElectric machineryVoltage

The invention provides an automatic cutting bed cutter deformation detection device. According to the device, the cutter deformation caused by cutting cloth in the rotation process of the cutter is detected in real time through a displacement sensor, and the detected analog voltage signal is subjected to digital transformation. Under the control of a program in a micro controller, firstly the cutter deformation is analyzed and judged, then a servo motor is controlled and the cutter is driven to carry out rotation compensation to the opposite direction of deformation, and the automatic correction of the cutter cutting direction is realized. The fact that the cutting error caused by the cutter deformation is always controlled in an allowable range is ensured, and the cutting quality and precision are raised.

Owner:MIANYANG WEIBO ELECTRONICS

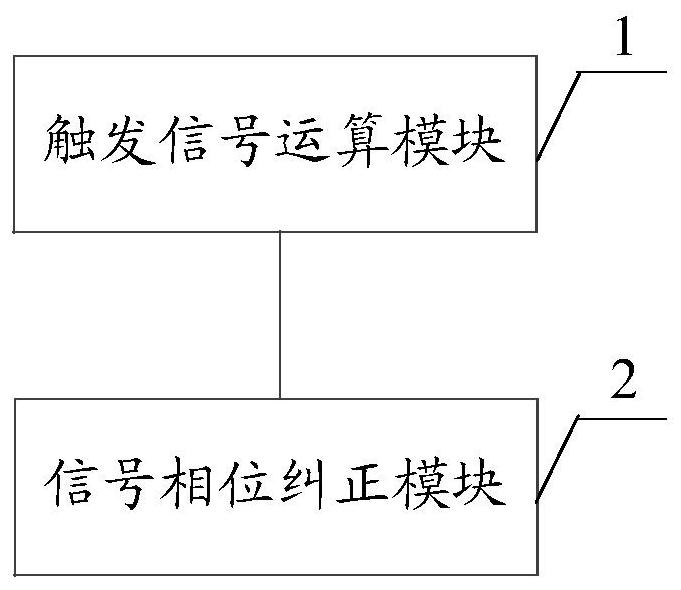

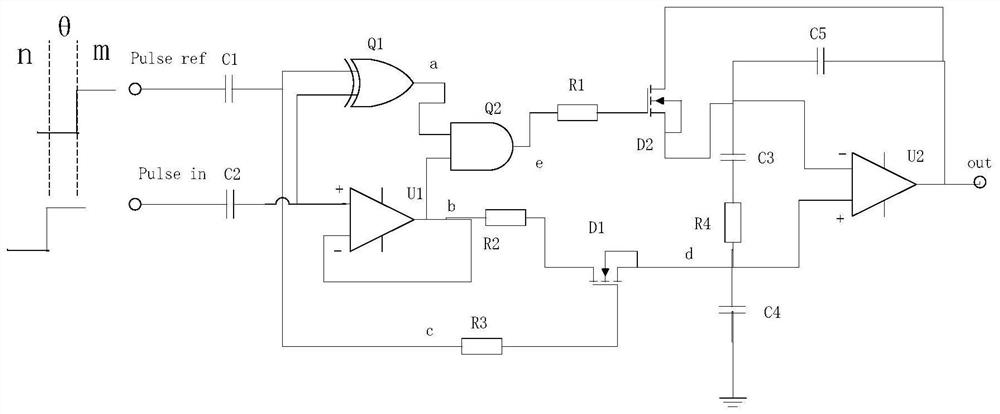

Phase self-correcting circuit

ActiveCN111817701AReduce manufacturing costLow pricePulse automatic controlDelay compensationPhase correctionEngineering

The invention discloses a phase self-correcting circuit. The phase self-correcting circuit comprises a trigger signal operation module and a signal phase correcting module, the trigger signal operation module and the signal phase correction module are both composed of a plurality of discrete components. The trigger signal operation module is used for performing logical operation on the input phasestandard reference signal and the actual transmission signal to obtain a target trigger signal of the trigger signal phase correction module; the signal phase correction module is used for outputtinga self-correction transmission signal with the same waveform as the phase standard reference signal based on the trigger mode of the target trigger signal and the actual transmission signal; the phase self-correction of the actual transmission signal is realized, so that the change of the signal phase caused by various external reasons is automatically corrected, the time sequence requirement ina long-distance transmission scene is met, and the whole circuit is simple in structure, high in universality and low in manufacturing cost.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

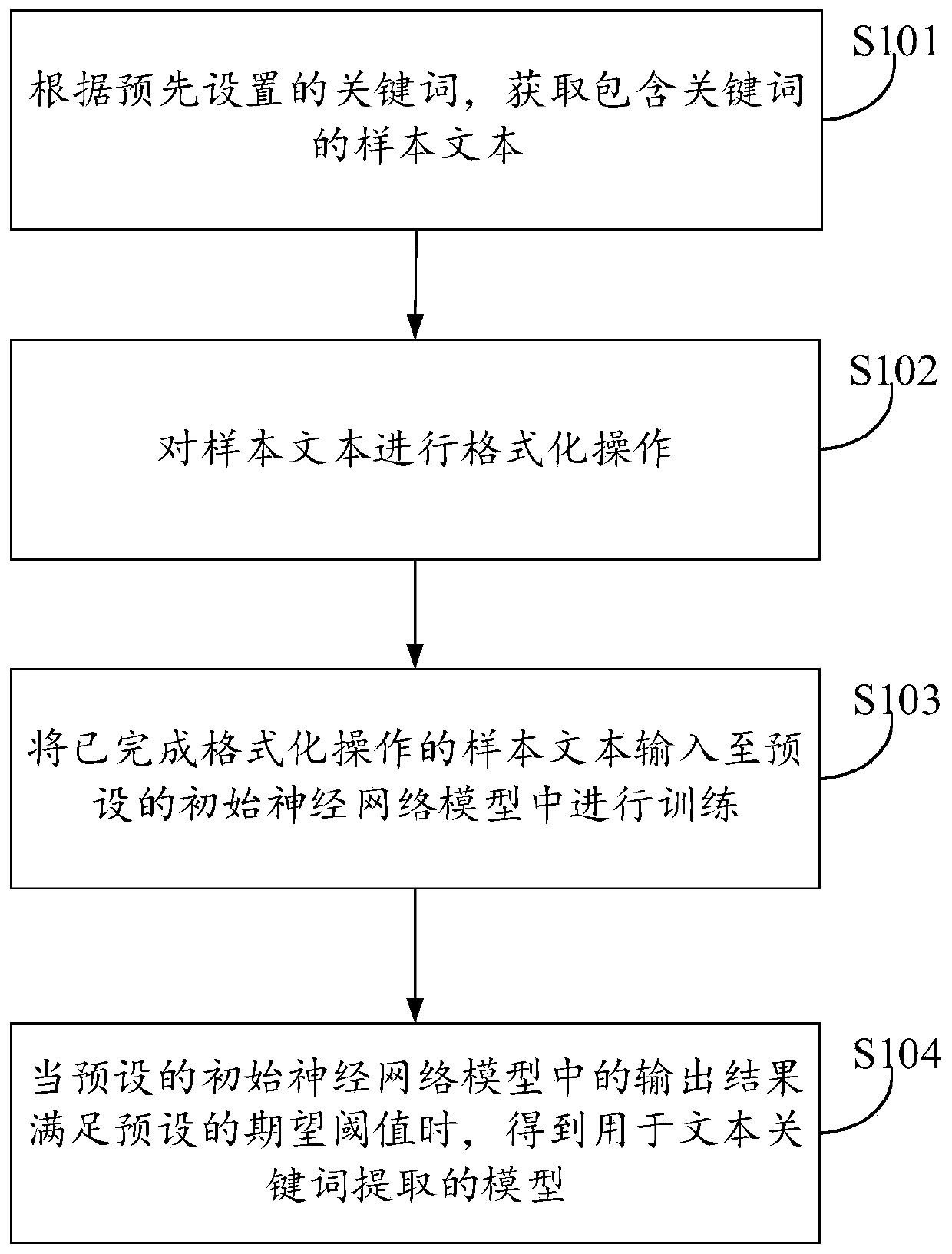

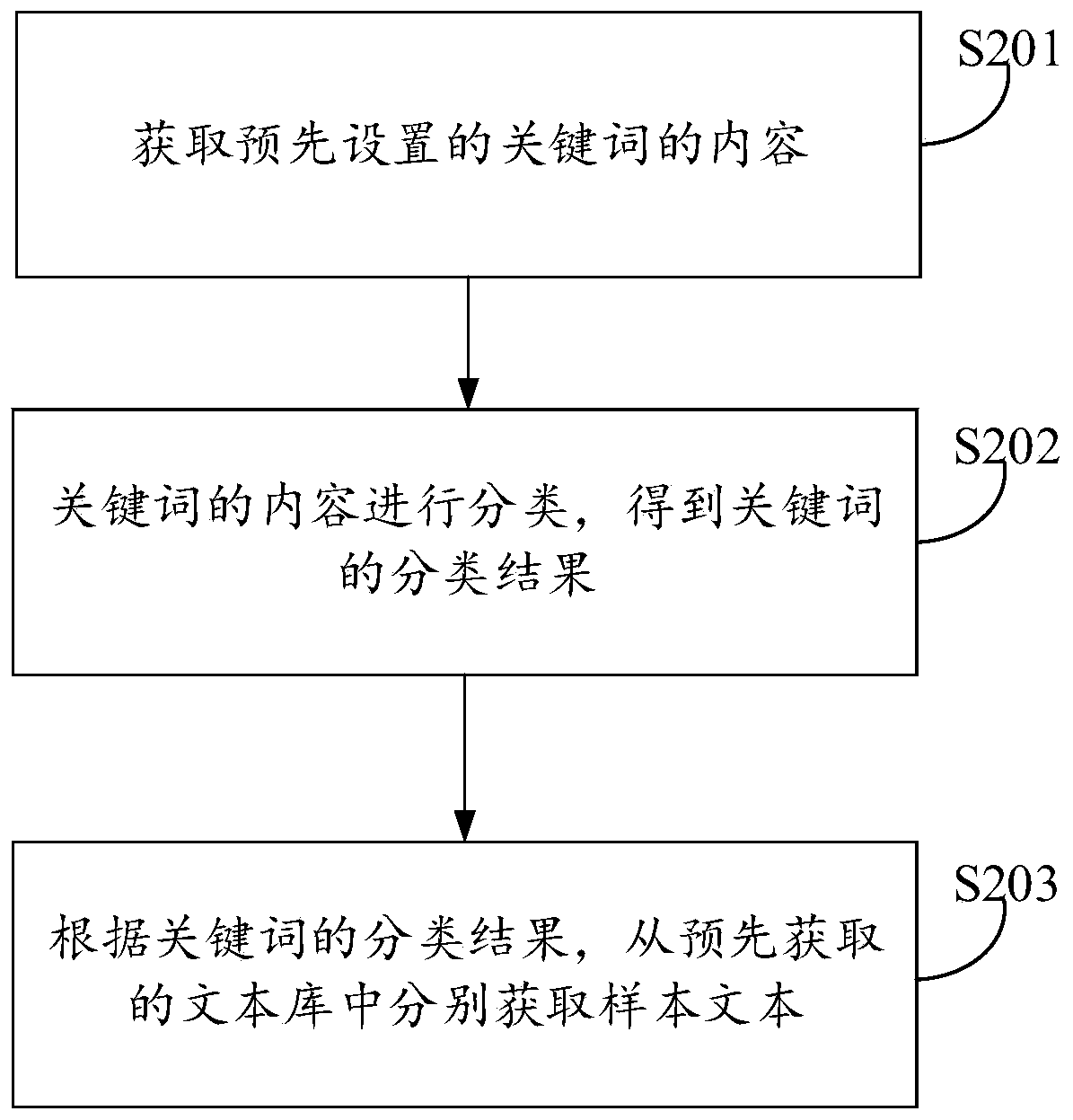

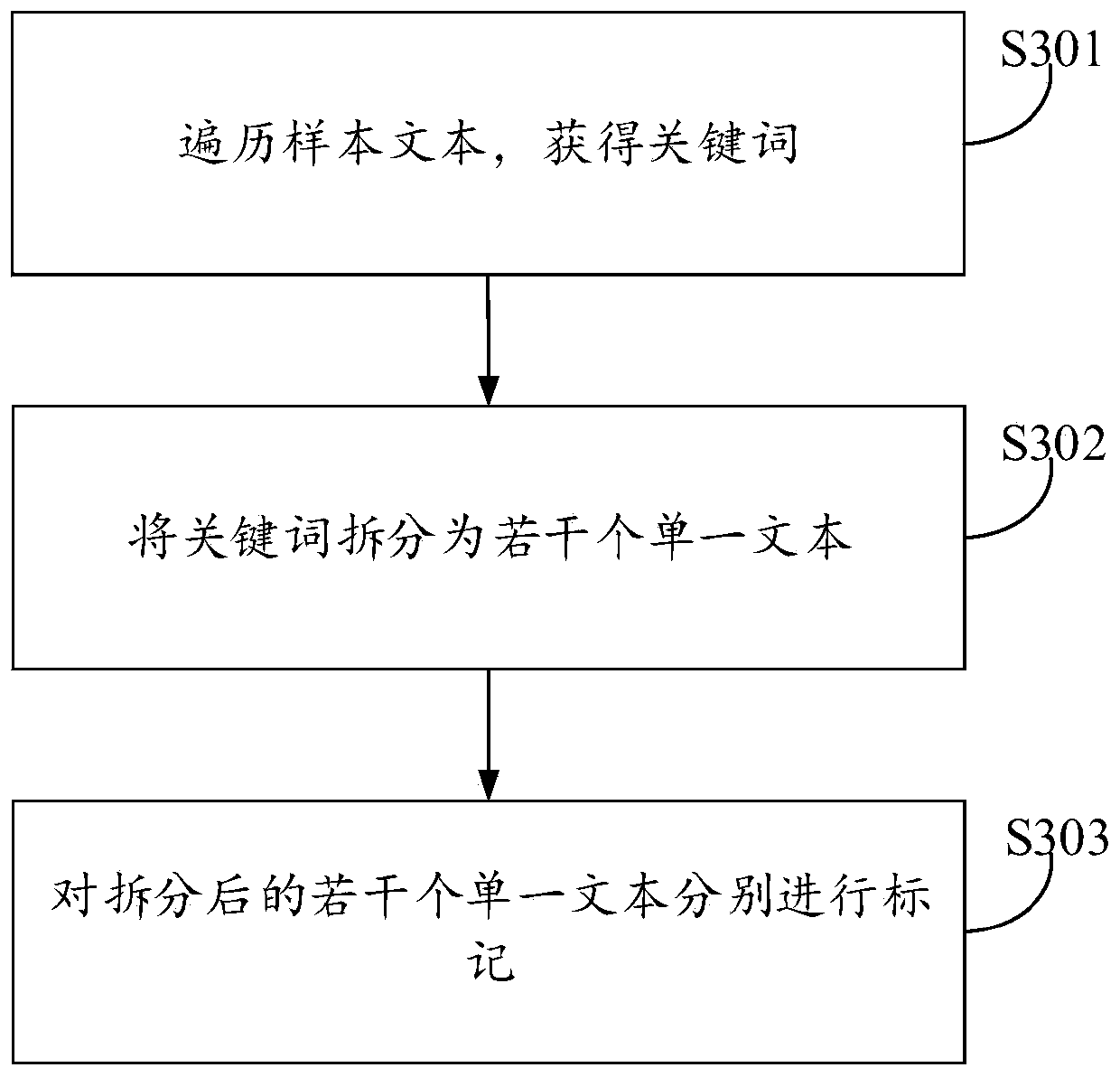

Text error correction method and model training method and device thereof

PendingCN111310473AAutomated ExtractionImplement auto-correctionNatural language data processingNeural architecturesAlgorithmText entry

The invention provides a text error correction method and a model training method and device thereof, and relates to the technical field of character recognition, and the model training method comprises the steps: obtaining a sample text containing keywords according to the preset keywords; formatting the sample text; inputting the sample text subjected to formatting operation into a preset initial neural network model for training; and when an output result in the preset initial neural network model meets a preset expected threshold, obtaining a model for text keyword extraction. A text to berecognized is input into a text keyword extraction model which is trained in advance, a text keyword extraction result is output, and the text keyword extraction result is compared with a preset standard file for error correction. The text keyword extraction model is obtained by training the neural network model, so that automatic extraction and automatic correction of the text keywords are realized, the manual operation process is reduced, and reduction of writing errors in the text is facilitated.

Owner:四川无声信息技术有限公司

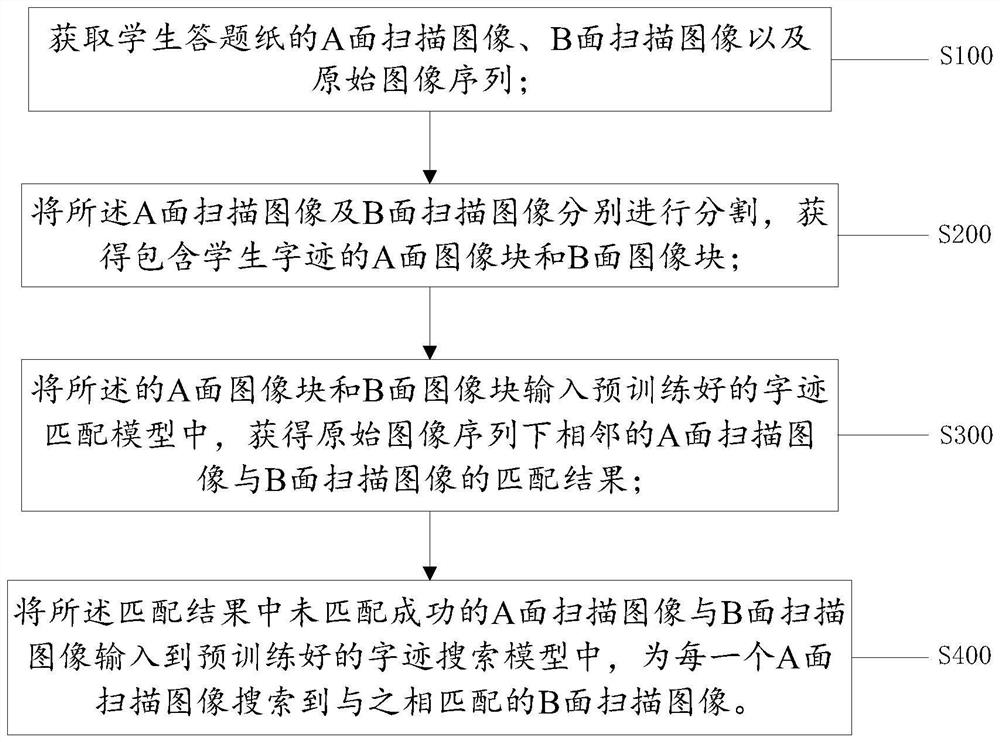

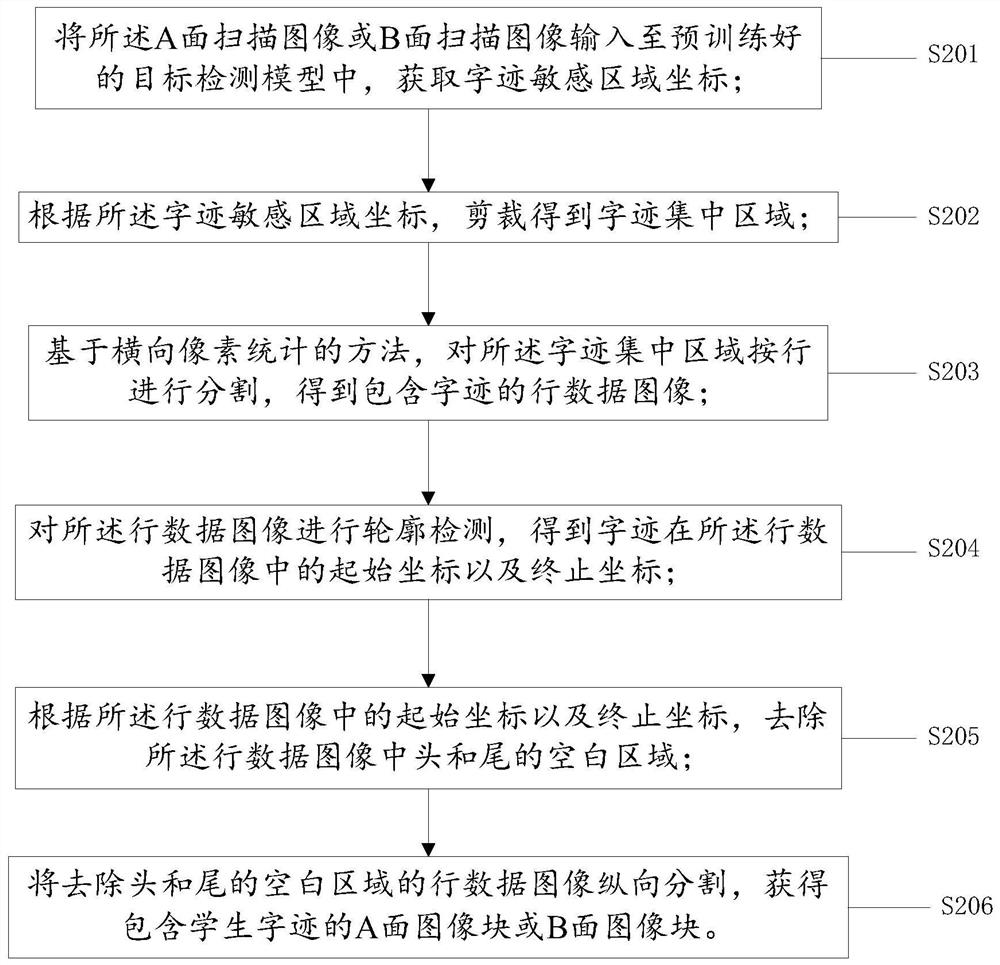

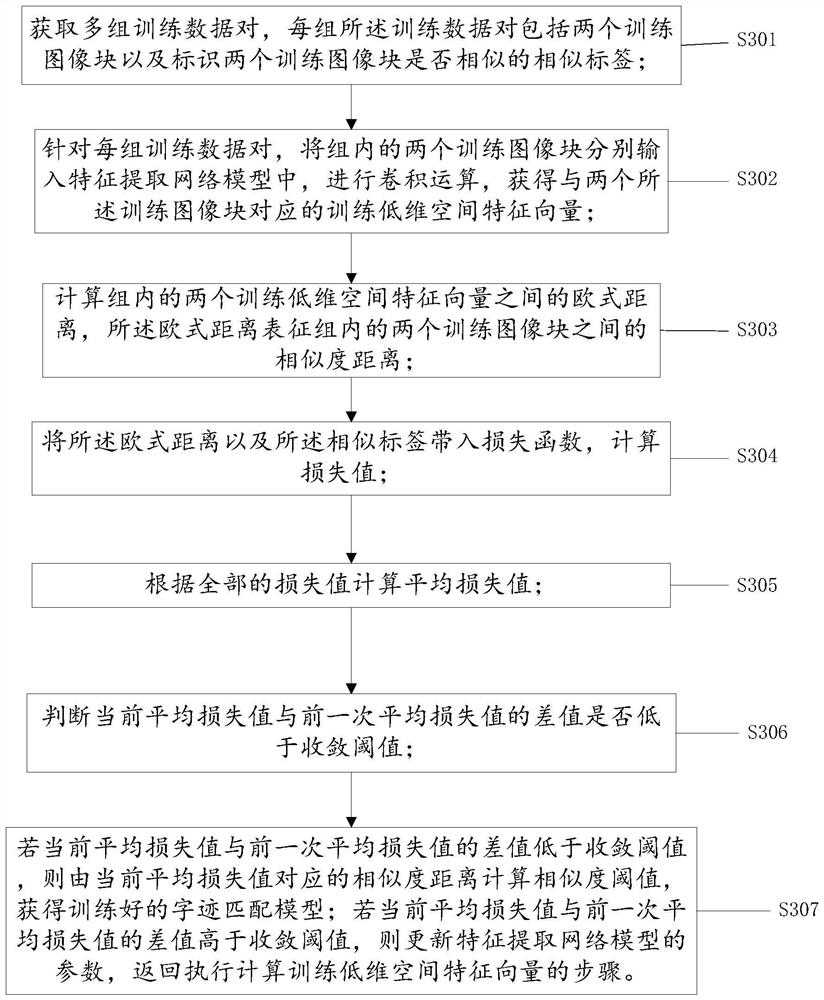

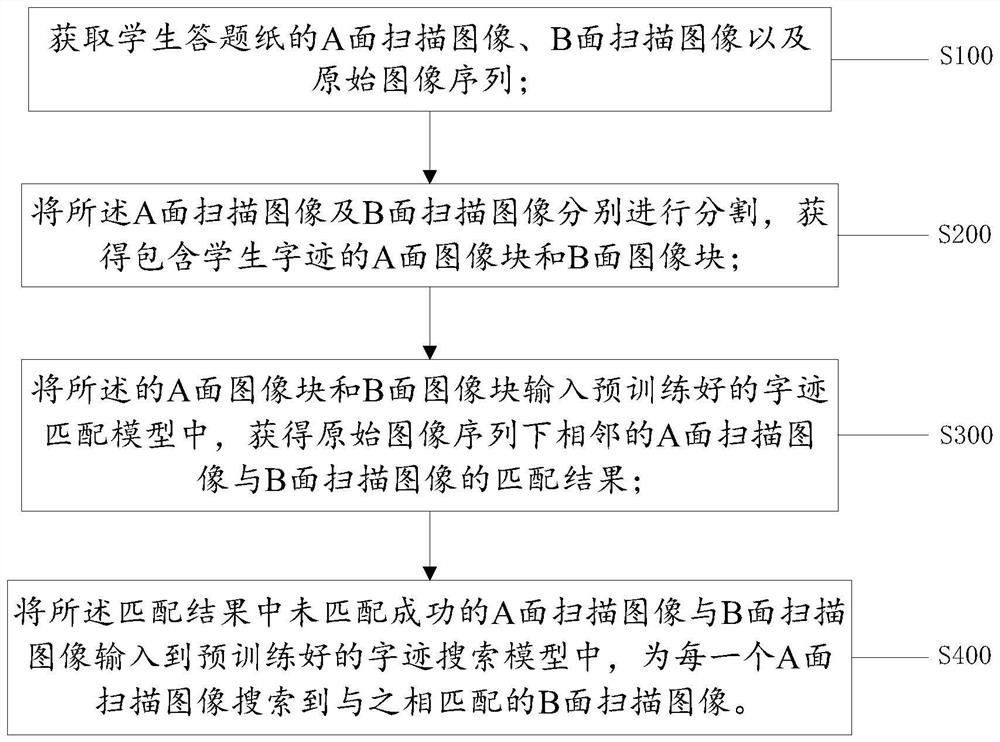

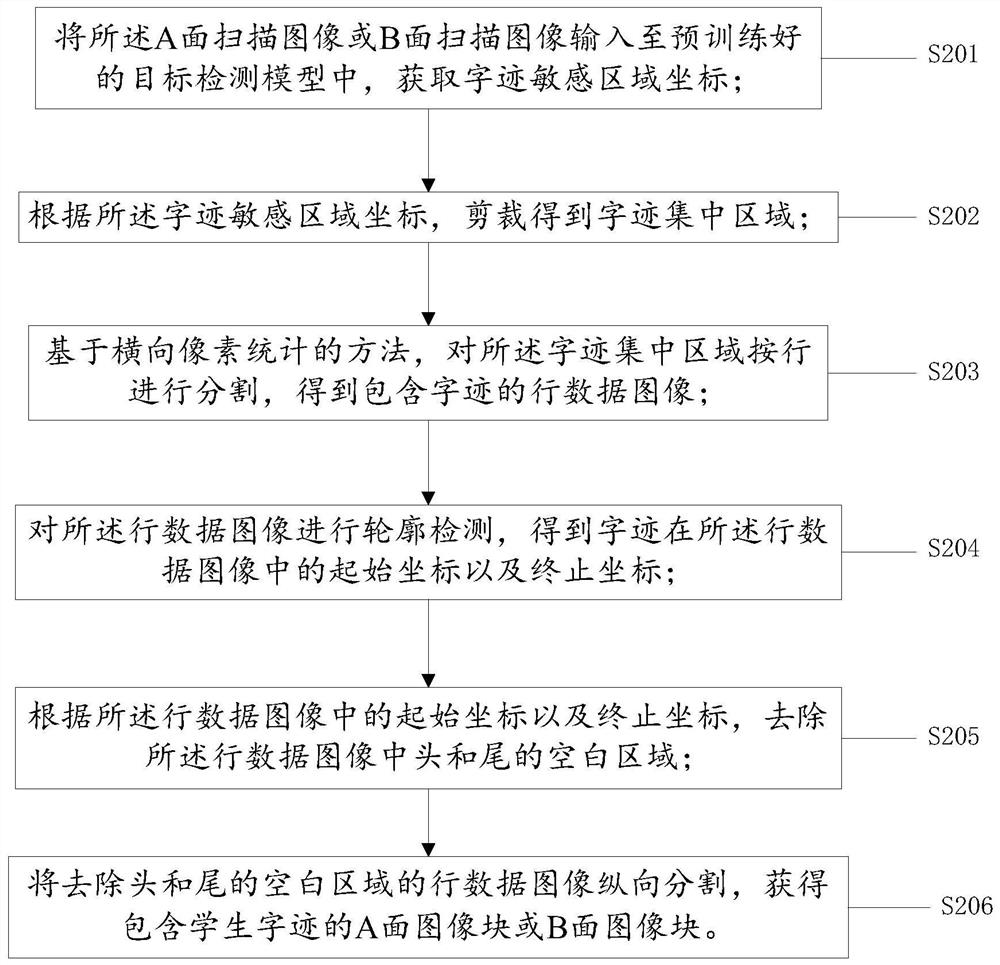

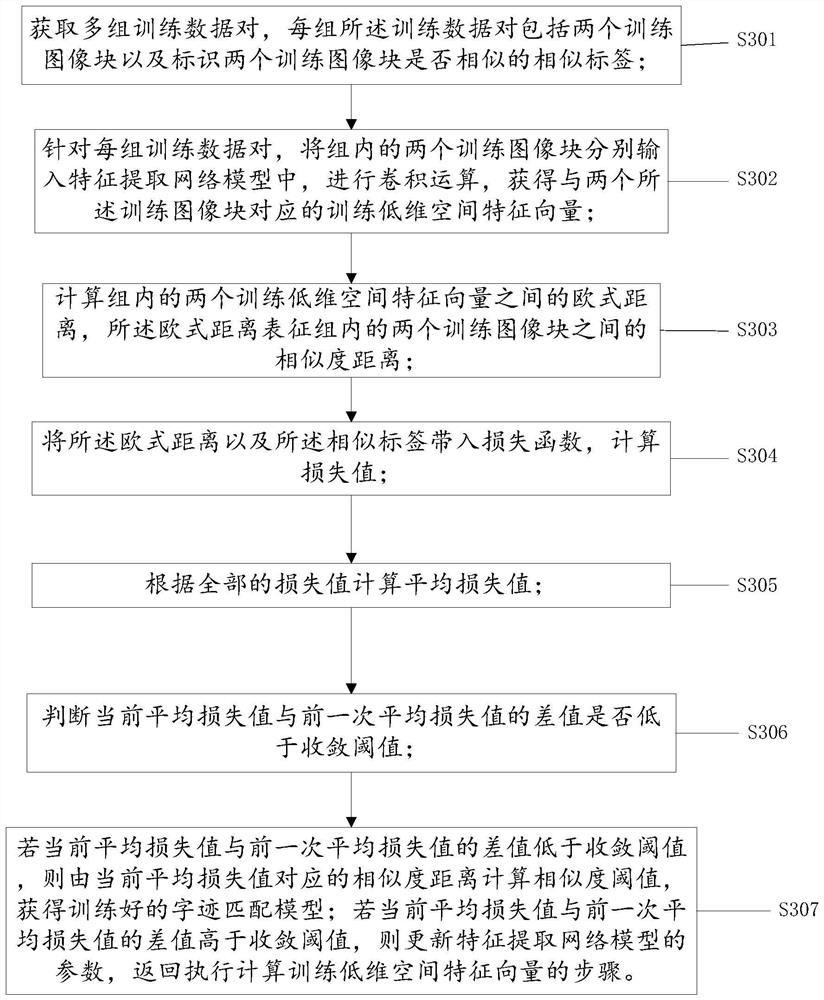

Self-adaptive answer sheet sequence correction method

ActiveCN112001416AImplement auto-correctionNeural architecturesNeural learning methodsPattern recognitionHandwriting

One or more embodiments of the invention provide a self-adaptive answer sheet sequence correction method. The self-adaptive answer sheet sequence correction method comprises the steps of obtaining anA-side scanning image, a B-side scanning image and an original image sequence of student answer sheets; respectively segmenting the A-side scanning image and the B-side scanning image to obtain an A-side image block and a B-side image block containing student handwriting; inputting the A-side image block and the B-side image block into a pre-trained handwriting matching model to obtain a matchingresult of an A-side scanning image and a B-side scanning image which are adjacent to each other under an original image sequence; and inputting the A-side scanning image and the B-side scanning imagewhich are not successfully matched in the matching result into a pre-trained handwriting search model, and searching the B-side scanning image matched with each A-side scanning image for each A-side scanning image, thereby realizing automatic correction of the answer sheet sequence.

Owner:BEIJING UNIV OF POSTS & TELECOMM

An online detection and correction system for laser shock processing based on workpiece vibration frequency

InactiveCN105316473BAvoid detectionAvoid evaluationOptically investigating flaws/contaminationOpto electronicNormal impact

The invention discloses an online detecting system for laser impact processing based on workpiece vibrating frequency. The online detecting system comprises a delay system, a control and vibration sensing system, wherein the delay system comprises an optical trigger and a delay; the optical trigger generates a pulse signal and sends the generated pulse signal to the delay; the pulse signal of the optical trigger is used as a trigger pulse signal of the vibration sensor for controlling a time quantum of the vibration sensor; the control and vibration sensing system comprises the vibration sensor, a computer, an automatic controller and a laser unit; the vibration sensor is used for acquiring a target material vibration signal; by virtue of A / D conversion, a digital signal is transmitted to the computer; and the digital signal is compared with vibration frequency during normal impact in a database to judge, and the signal is transmitted to the automatic controller to regulate power of the laser unit. The online detecting and correcting system can realize online detection and automatic correction for laser impact, so that impact speed is increased and impact efficiency is improved; and the online detecting and correcting system is low in requirement on an external environment, low in cost, stable and reliable.

Owner:LIANYUNGANG NORMAL COLLEGE

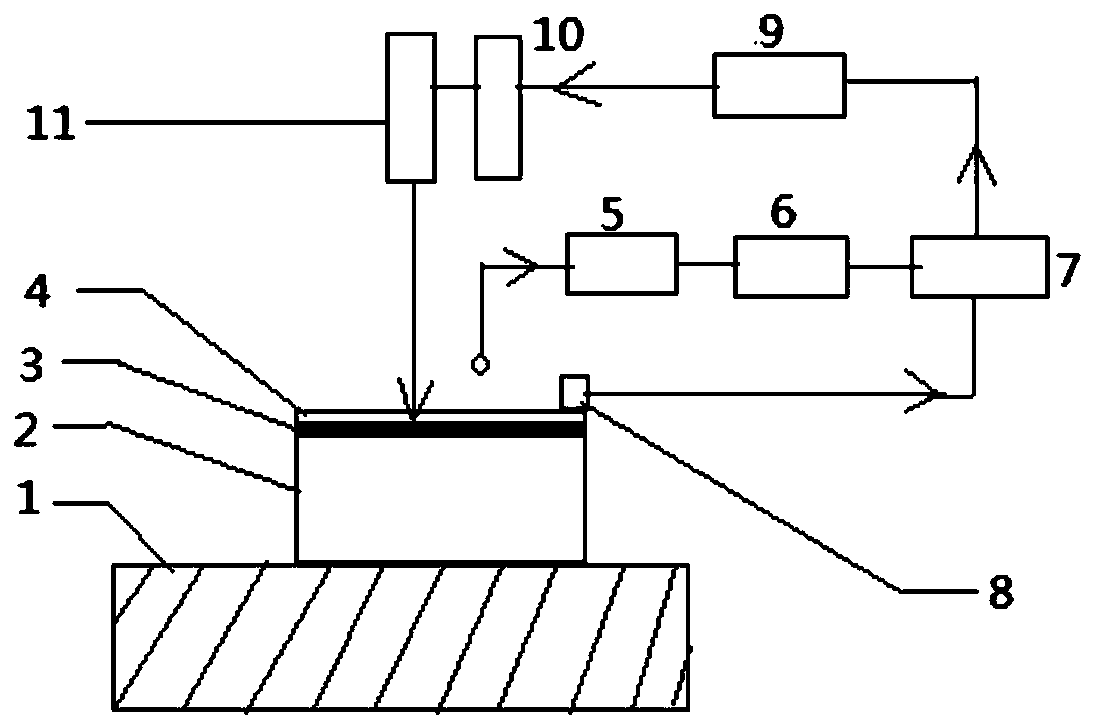

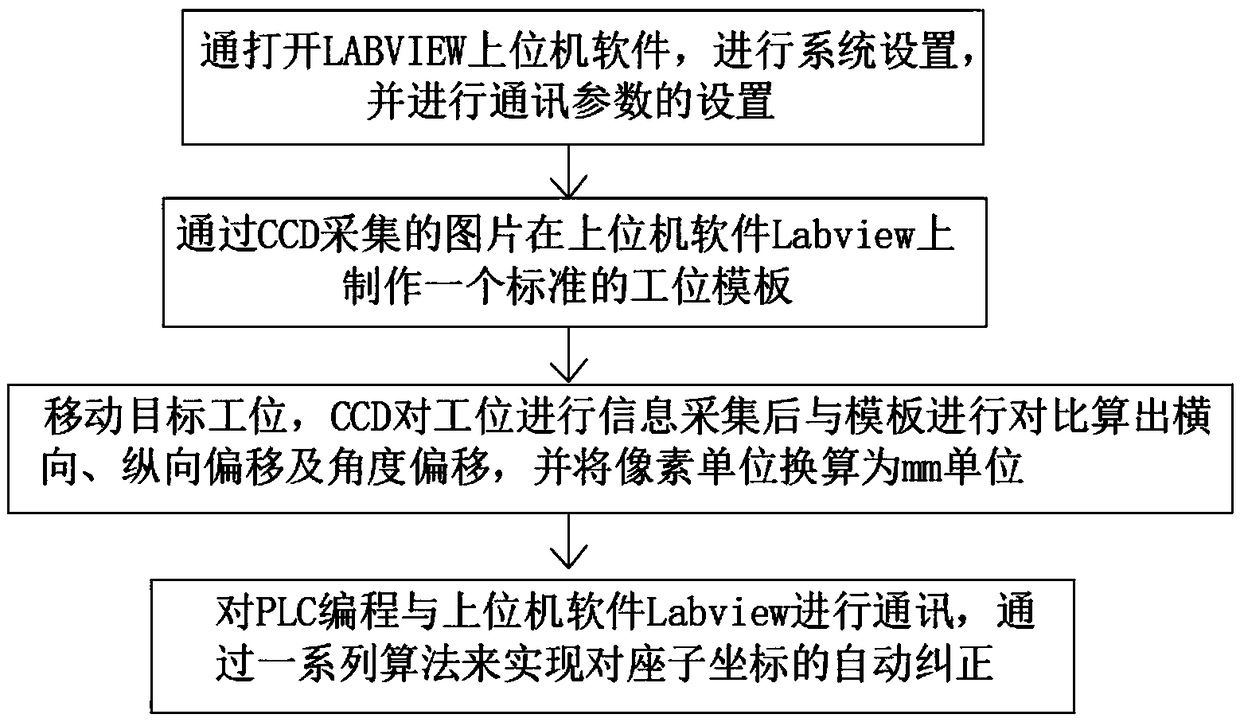

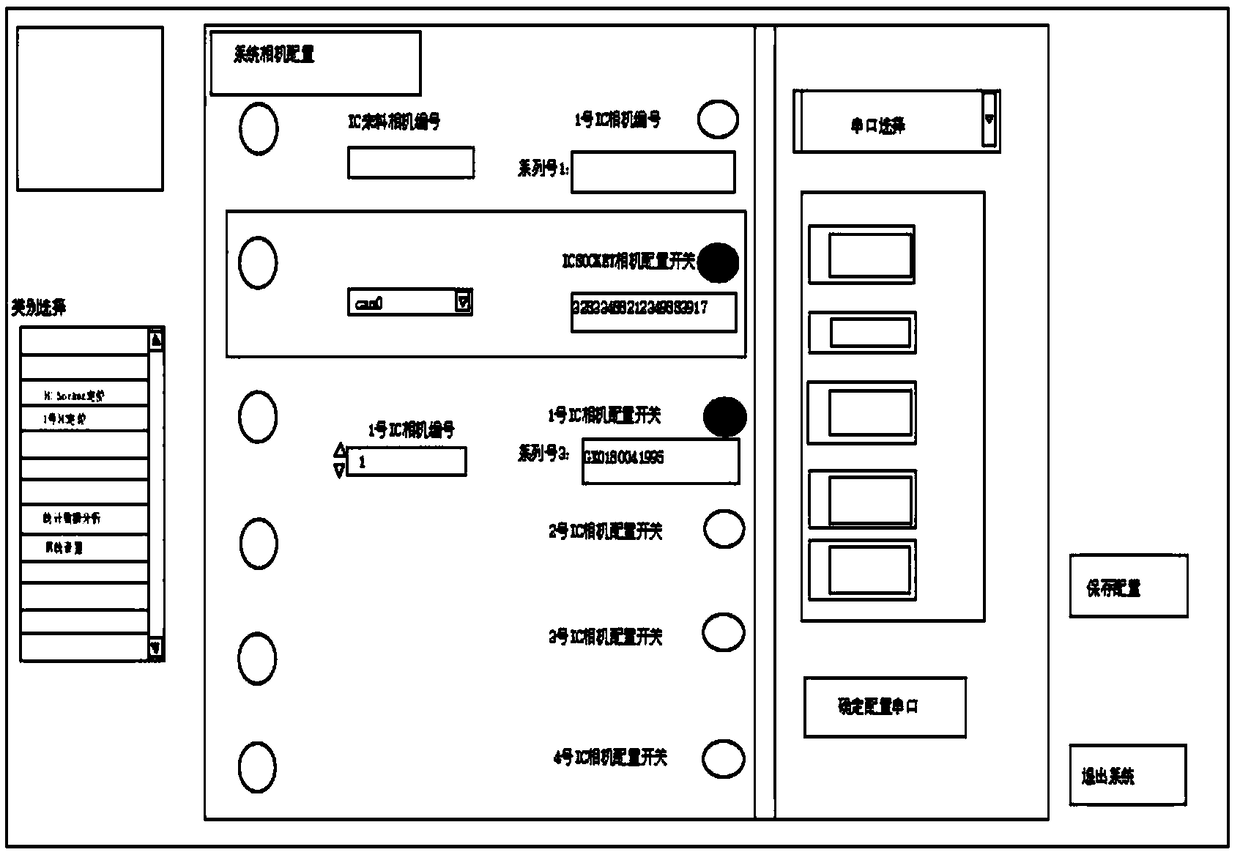

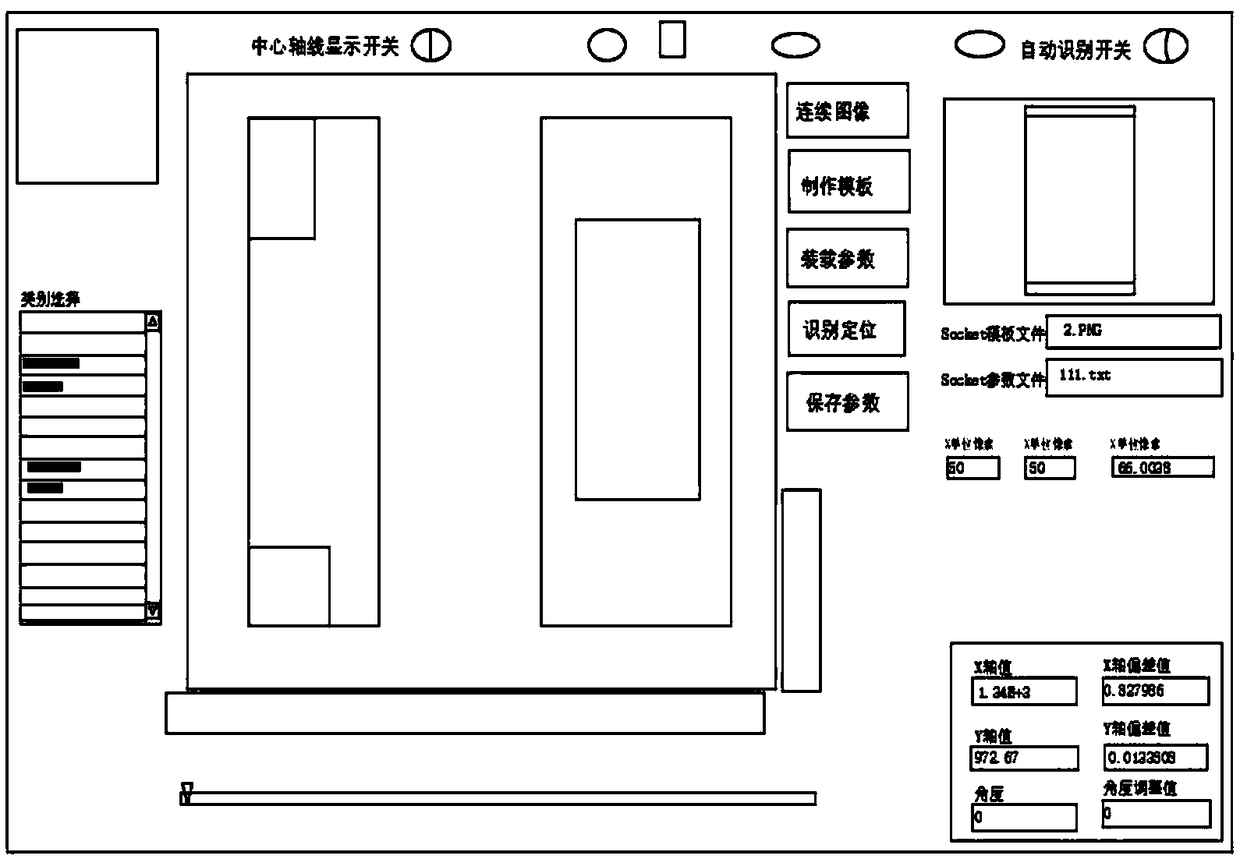

Method of automatically judging azimuth of burning seat based on CCD vision

InactiveCN109341594AImplement auto-correctionReduce errorsUsing optical meansComputer softwareVisual perception

The invention discloses a method of automatically judging the azimuth angle of a burning base based on CCD vision, which includes the following steps: making a standard position template on the uppercomputer software Labview based on the information acquired by CCD; comparing the position information obtained through a second examination of it by CCD against the template, calculating the horizontal, vertical and angular offsets, and converting the pixel units into the unit of mm; Communicating with the host computer software Labview through programming PLC, obtaining information, and then carrying out in PLC an automatic correction of the coordinates of the seat through a series of algorithms. The invention calculates the horizontal, vertical and angular offsets by comparing the positioninformation collected by CCD against the template, obtains the offset information, and then realizes the automatic correction of the coordinates of the burning seat through a series of algorithms in PLC. The method is more accurate in calibrating coordinates and reduces the errors caused by manual naked eye alignment. Besides, it is easy to operate and improves the work efficiency.

Owner:SHENZHEN KINGCOS AUTOMATION ROBOT EQUIP CO LTD

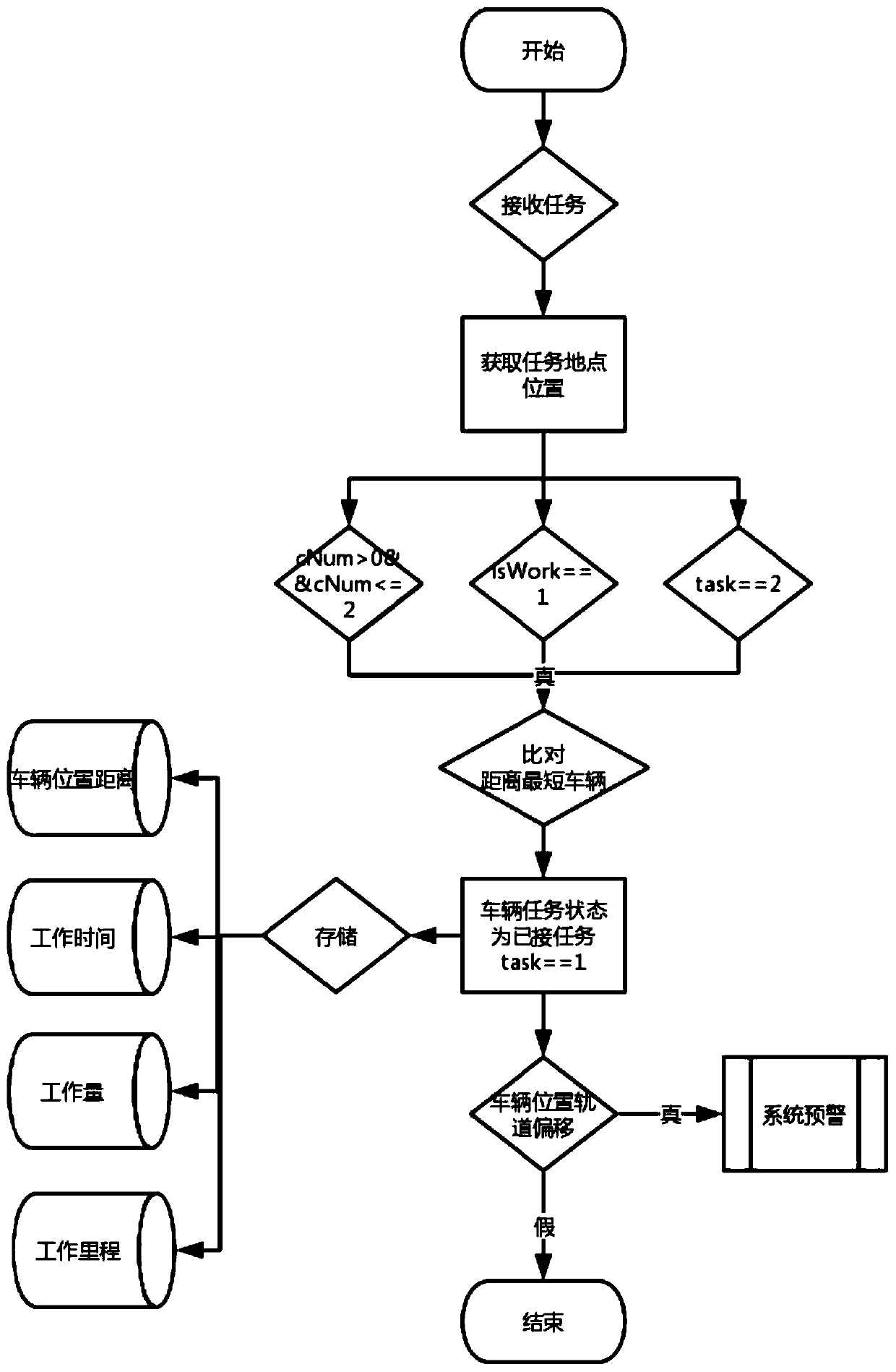

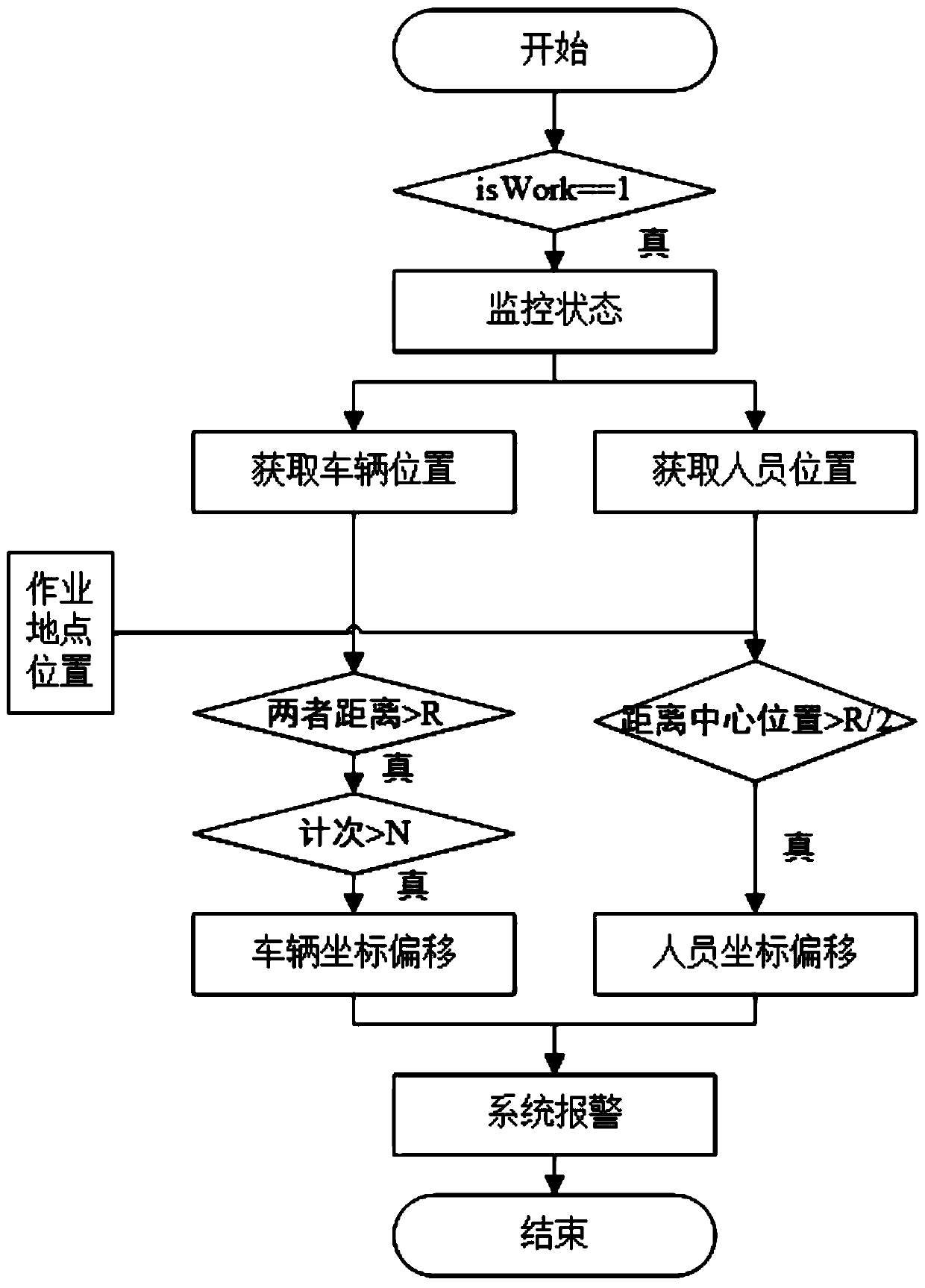

Outdoor work monitoring and management method based on multi-coordinate triaxial positioning algorithm

InactiveCN109982261ARealize monitoringAchieve task meteringParticular environment based servicesVehicle wireless communication serviceSite locationWorkload

The invention discloses an outdoor work monitoring and management method based on multi-coordinate triaxial positioning algorithm. The method comprises the steps that after a task is received, position coordinates of a task place are obtained, operation vehicles are distributed according to the position coordinates of the task place and the distance between a task-free operation vehicle and the task place, the distributed operation vehicles are distributed for working staff, and the position distance, the workload, the working time and the working mileage of the distributed operation vehiclesare recorded; and after the vehicle enters the operation state, real-time coordinates of the operation vehicle and the operation personnel on the vehicle are obtained in real time in the operation period, the operation vehicle and the operation personnel are positioned through a multi-coordinate three-axis positioning algorithm, and when the coordinates of the operation vehicle and / or the operation personnel deviate, an alarm is given. According to the invention, the operator can be compared with the operation vehicle and the operation site coordinates, the operator and the vehicle in a limited range can be positioned, and the monitoring of the operator and the operation vehicle can be realized.

Owner:TIANJIN SINO GERMAN VOCATIONAL TECHNICAL COLLEGE

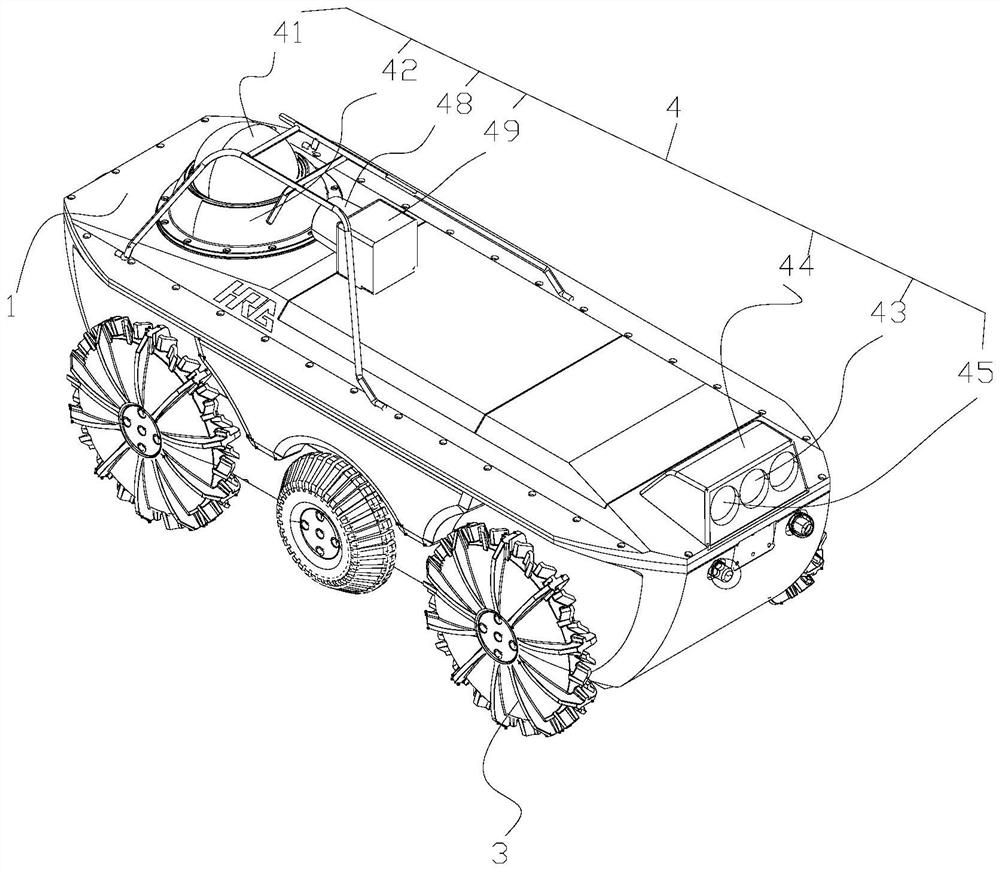

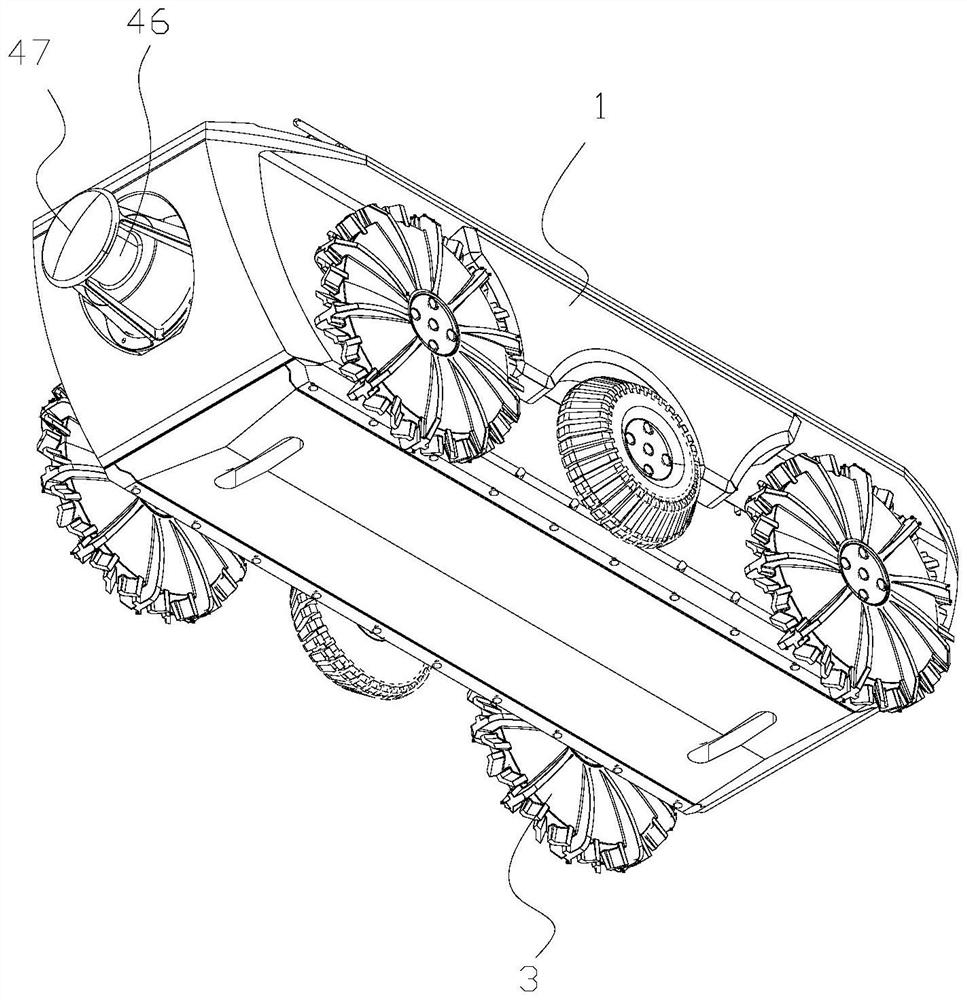

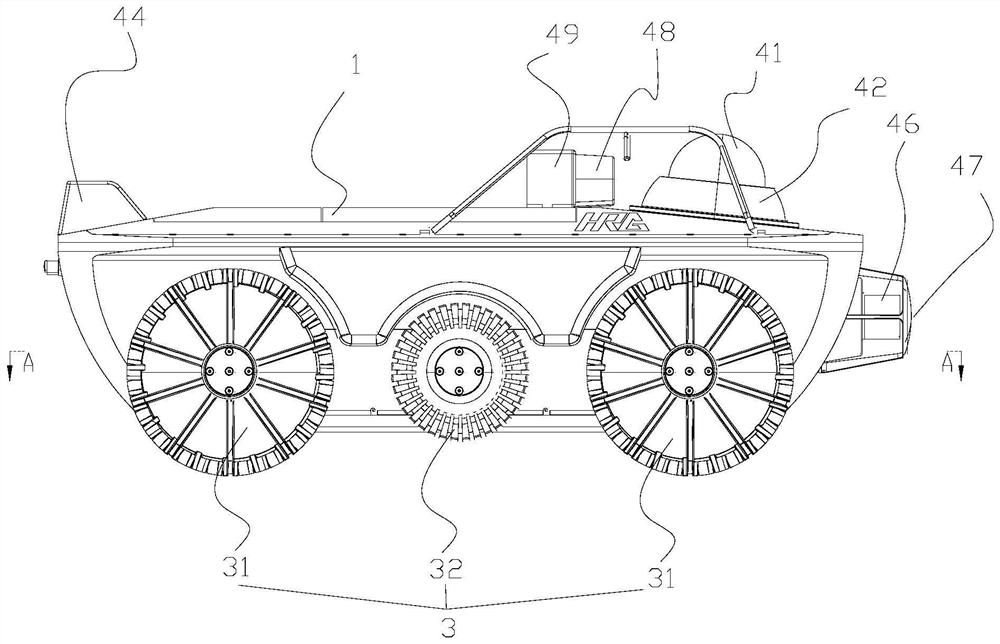

Pipeline detection robot

PendingCN114738598ASatisfy buoyancy requirementsLower center of gravityVehicular energy storagePigs/molesBalancing machineWater flow

The pipeline detection robot comprises a machine body assembly, a driving assembly, a wheel assembly, a detection assembly and a power source, the driving assembly and the power source are connected into the machine body assembly, the driving assembly is connected with the wheel assembly, and the detection assembly is connected with the outer surface of the machine body assembly; the driving assembly and the detection assembly are connected with the power supply; the machine body assembly comprises a first shell, a second shell and buoys, the first shell is connected with the second shell in a sealed mode, the buoys are connected with the two sides of the second shell, and the buoys are located above the wheel assembly; and the side part of the first shell or / and the second shell extends outwards to form a wing. The robot has the beneficial effects that the wings and the buoy are matched to form a water baffle, interference of water spray to the detection assembly is prevented, meanwhile, swing of the robot is balanced, and the horizontal posture is kept; the whole structure is light in weight, large in buoyancy and high in strength, and pipeline detection under the conditions of high water flow velocity and full water can be met.

Owner:HRG INT INST FOR RES & INNOVATION

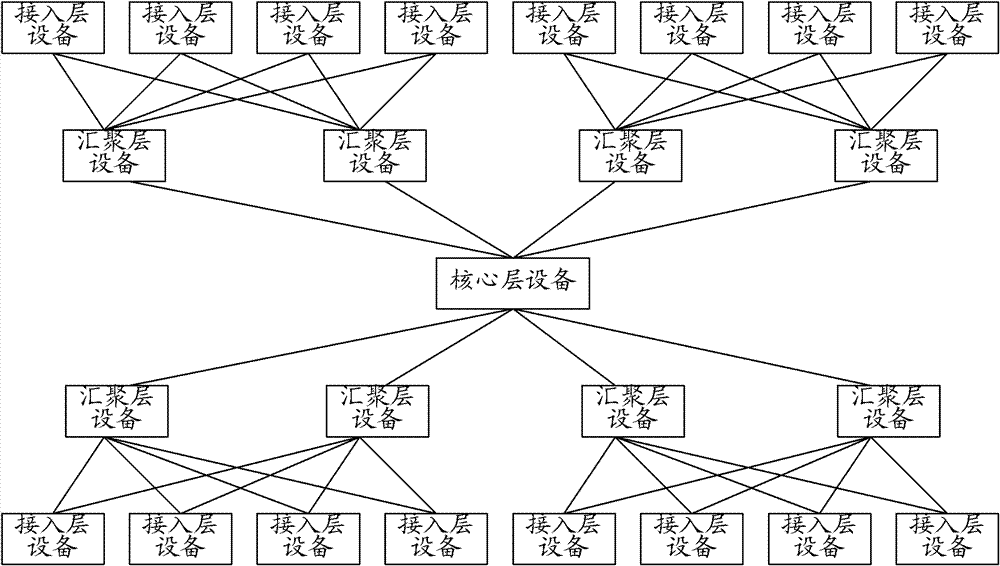

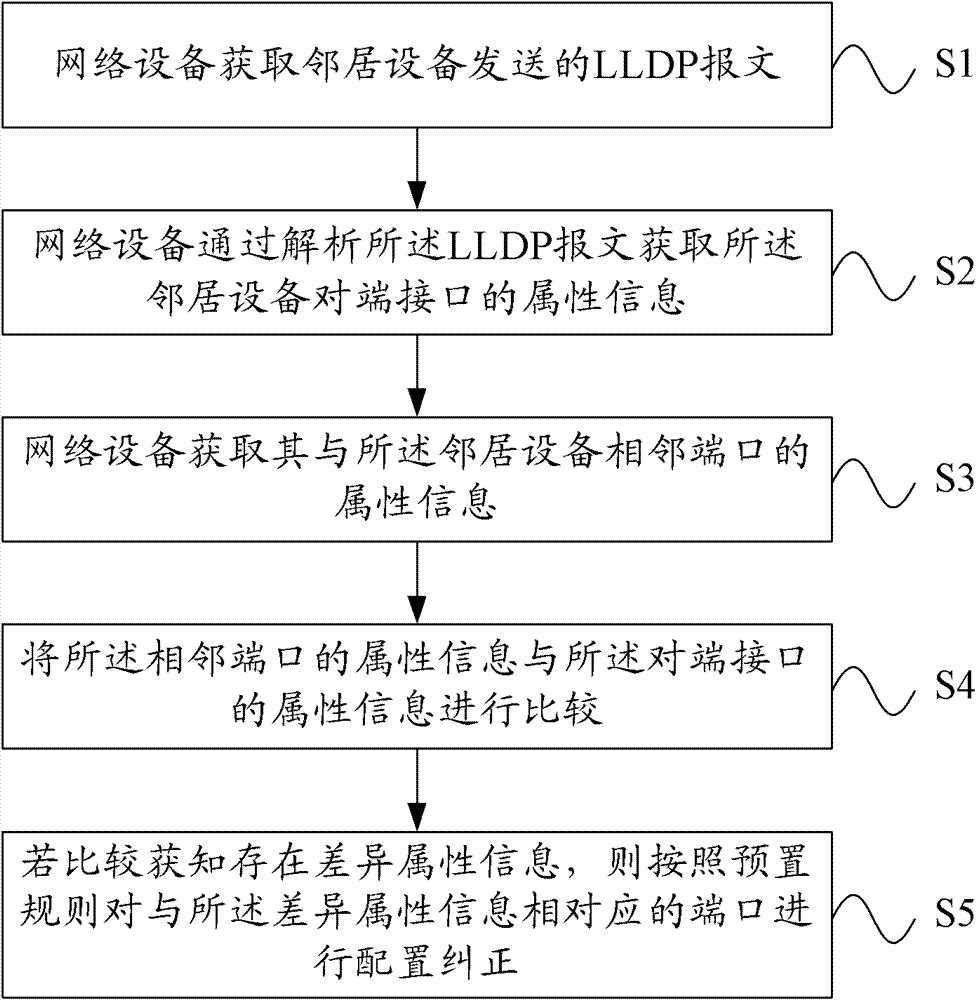

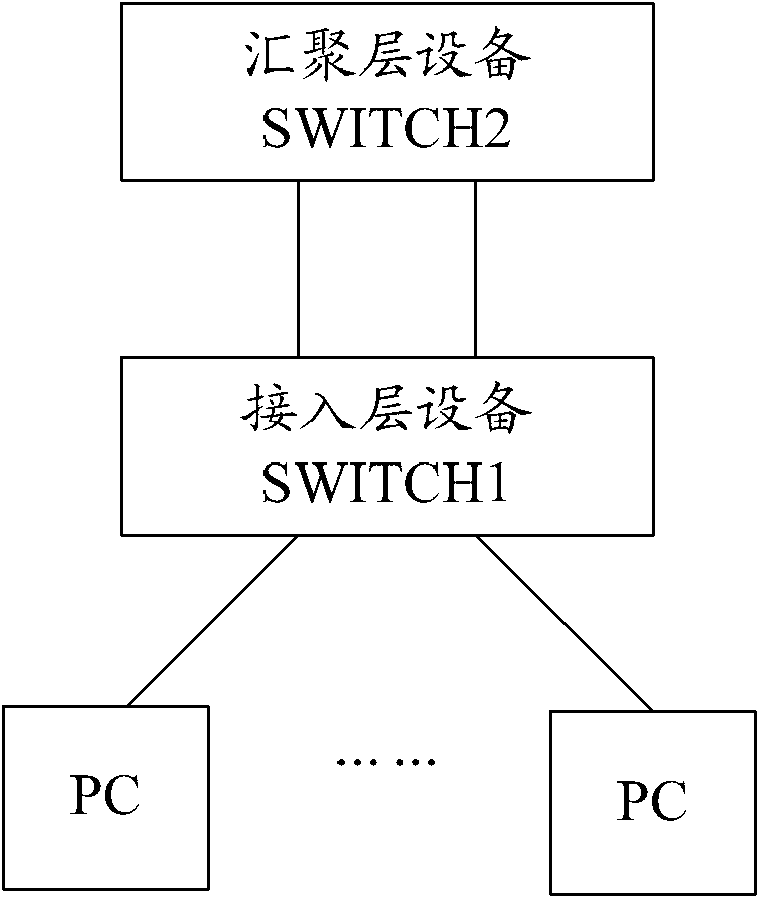

Network device configuration correcting method and network device

ActiveCN102123104BImplement auto-correctionEnergy efficient ICTData switching networksComputer networkLink Layer Discovery Protocol

The invention provides a network device configuration correcting method and a network device. The method comprises: the network device discovers a Link Layer Discovery Protocol (LLDP) message sent by a neighbor device; the network device analyzes the LLDP message to obtain the attribute information of the opposite-end interface of the neighbor device; the network device acquires the attribute information of the adjacent port of the neighbor device; the attribute information of the adjacent port is compared with the attribute information of the opposite-end interface; and if differential attribute information exists through the comparison, configuration correction is carried out on the interface corresponding to the differential attribute information according to a preset rule. By utilizing the network device configuration correcting method and network device provided by the invention, the automatic configuration correcting can be realized when the port configuration is detected to be incorrect, so that the stability and reliability of the network are improved.

Owner:RUIJIE NETWORKS CO LTD

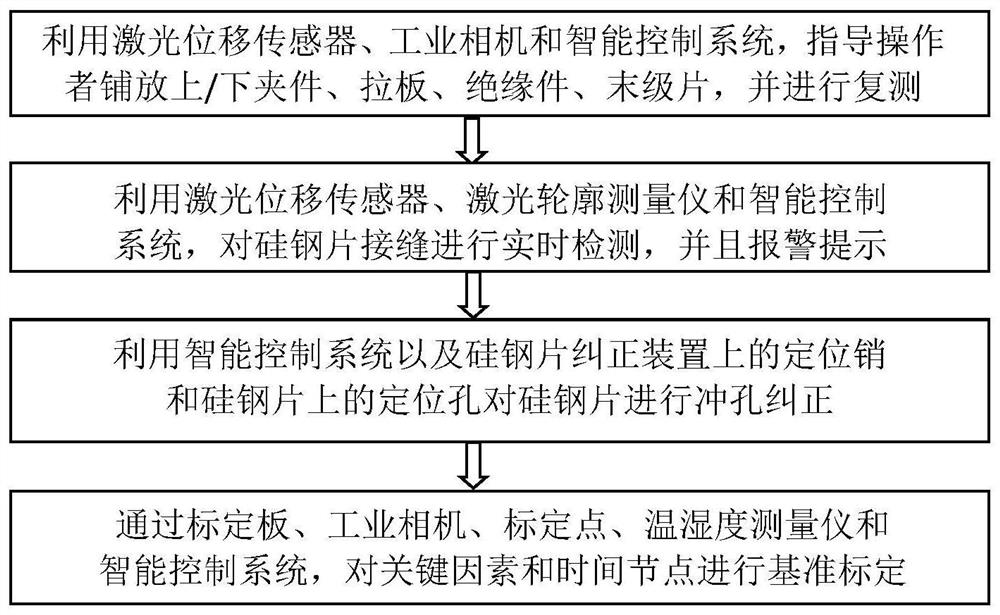

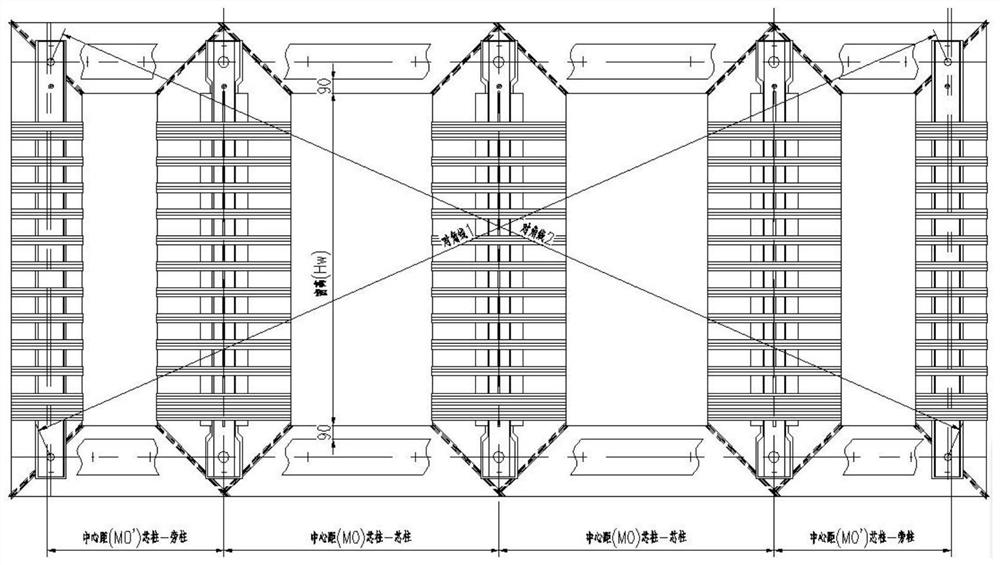

Auxiliary process method for automatically stacking iron cores

PendingCN113903581AFast layingAccurate layingMagnetic core manufactureEngineeringMechanical engineering

The invention relates to an auxiliary process method for automatically stacking iron cores. The method comprises the following steps of guiding an operator to lay an upper / lower clamping piece, a pulling plate, an insulating piece and a final-stage piece by using a laser displacement sensor, an industrial camera and an intelligent control system, and retesting after laying; using the laser displacement sensor, a laser profile measuring instrument and the intelligent control system for detecting the seam of the silicon steel sheets in real time, and if the seam distance exceeds the tolerance range or the two silicon steel sheets are overlapped, alarming and prompting; using the intelligent control system, a positioning pin on a silicon steel sheet correcting device and the positioning holes in the silicon steels sheets to punch and correct the silicon steel sheets; carrying out reference calibration on the key factors and time nodes through a calibration plate, an industrial camera, a calibration point, a temperature and humidity measuring instrument and the intelligent control system. According to the invention, auxiliary accessories for iron core stacking are more quickly and accurately laid, the condition that the seam size meets the process requirement is ensured, and the automatic correction of the positions of the silicon steel sheets in the iron core stacking process is realized.

Owner:SHANDONG POWER EQUIP

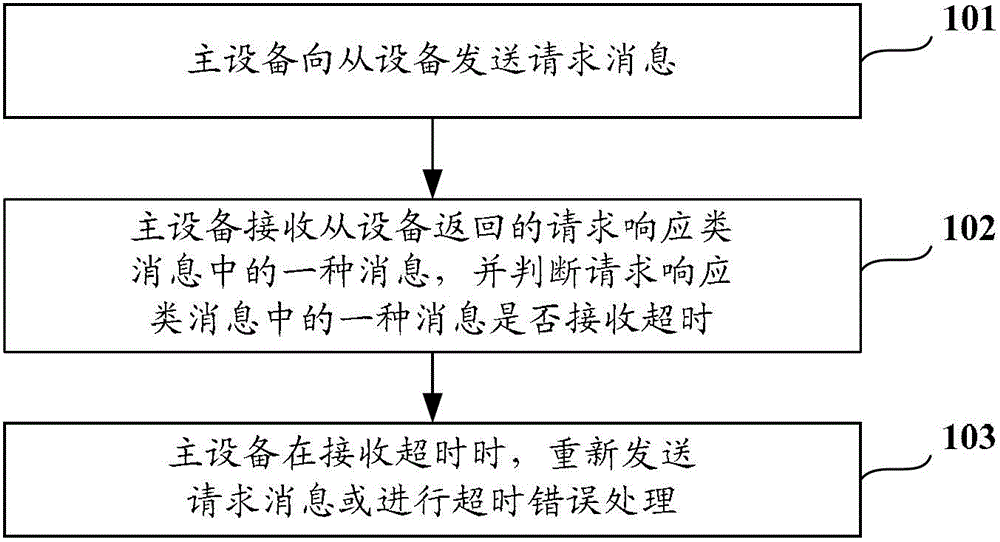

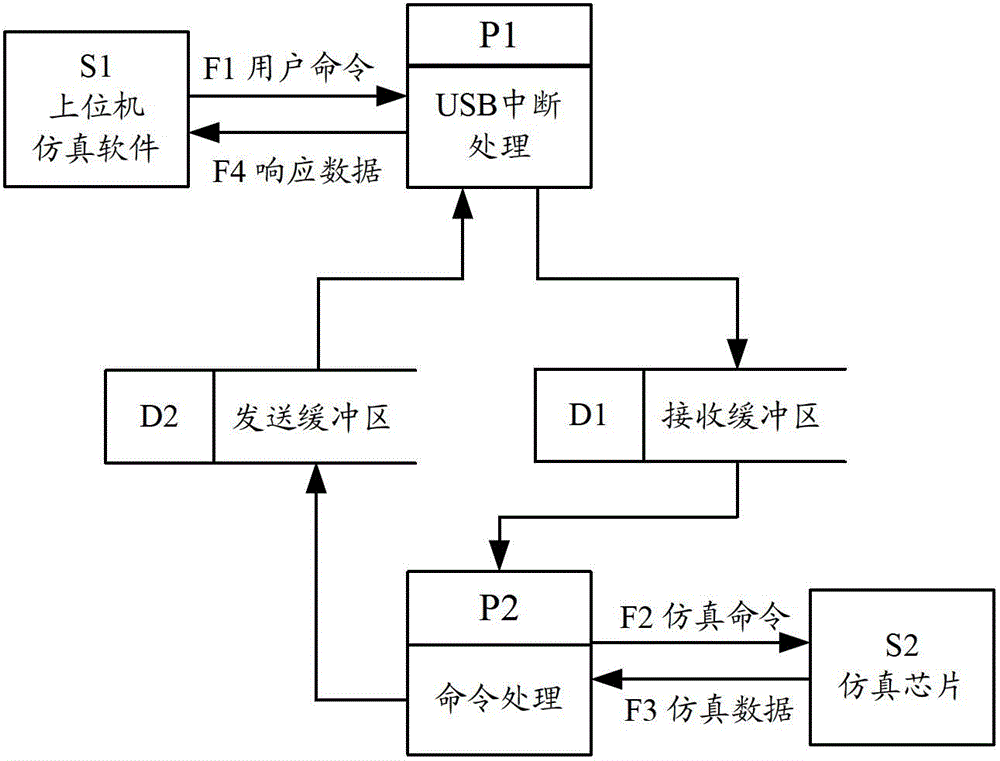

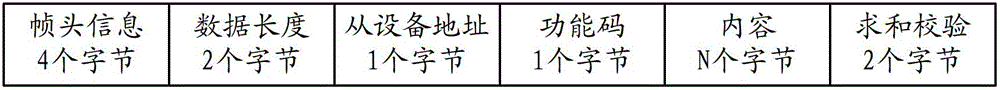

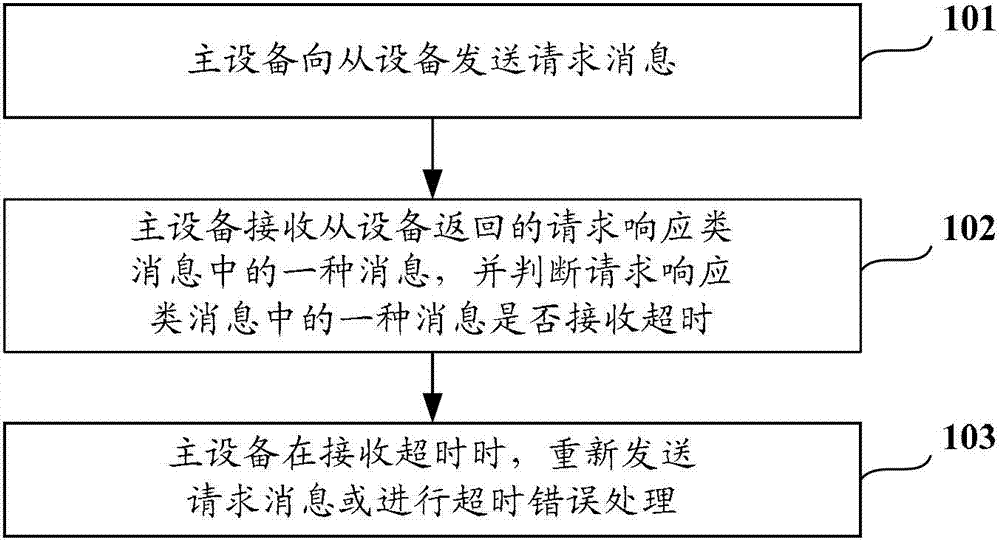

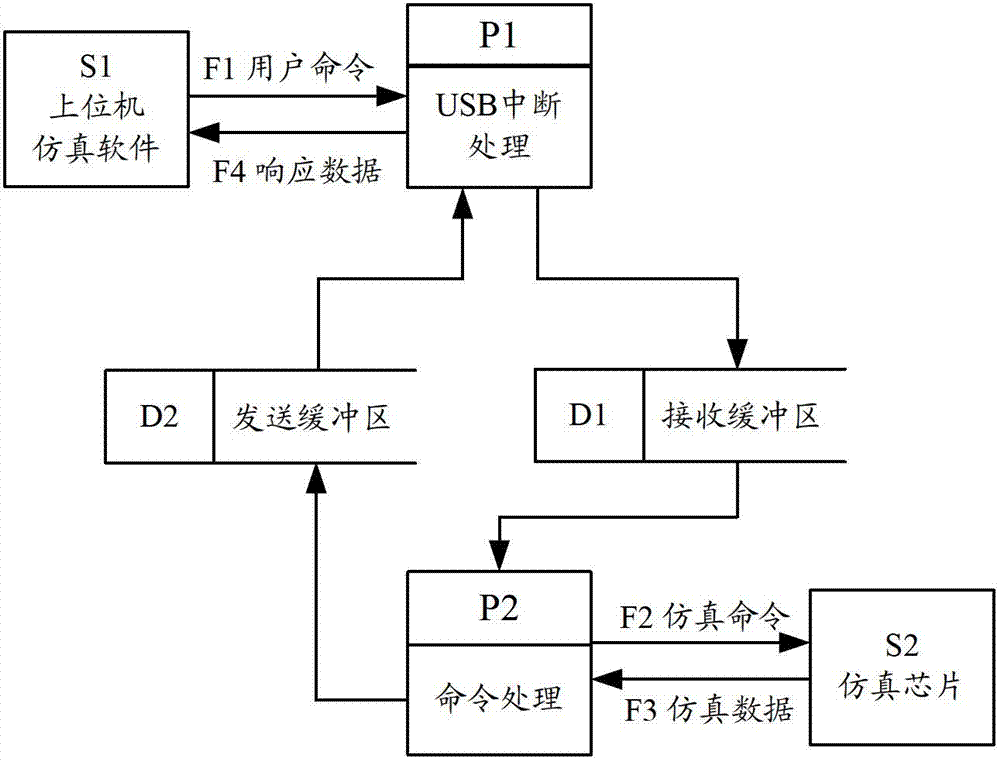

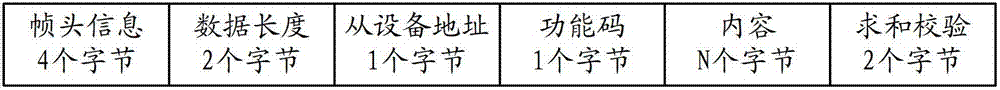

Simulation system communication method and simulation system

ActiveCN104038309AAvoid false positivesImprove anti-interference abilityError prevention/detection by using return channelError processingMessage processing

The invention provides a simulation system communication method and a simulation system. The method comprises the following steps that: a master device sends a request message to a slave device; the master device receives one of request response type messages returned by the slave device and determines whether a receiving timeout phenomenon of the one of request response type messages occurs, wherein the request response type message include a first message processing result that is returned by the slave device when determining the request message is a first message and a request message response message that is returned by the slave device when determining the request message is a second message; and when a receiving timeout phenomenon occurs at the master device, the request message is sent again or timeout error processing is carried out. With the method and the system, a problem of a communication failure or a simulation data error due to the interference on the simulator can be solved, thereby realizing improvement of the anti-interference performance and stability of the simulator; and the automatic correction can also be realized.

Owner:SHANGHAI EASTSOFT MICROELECTRONICS

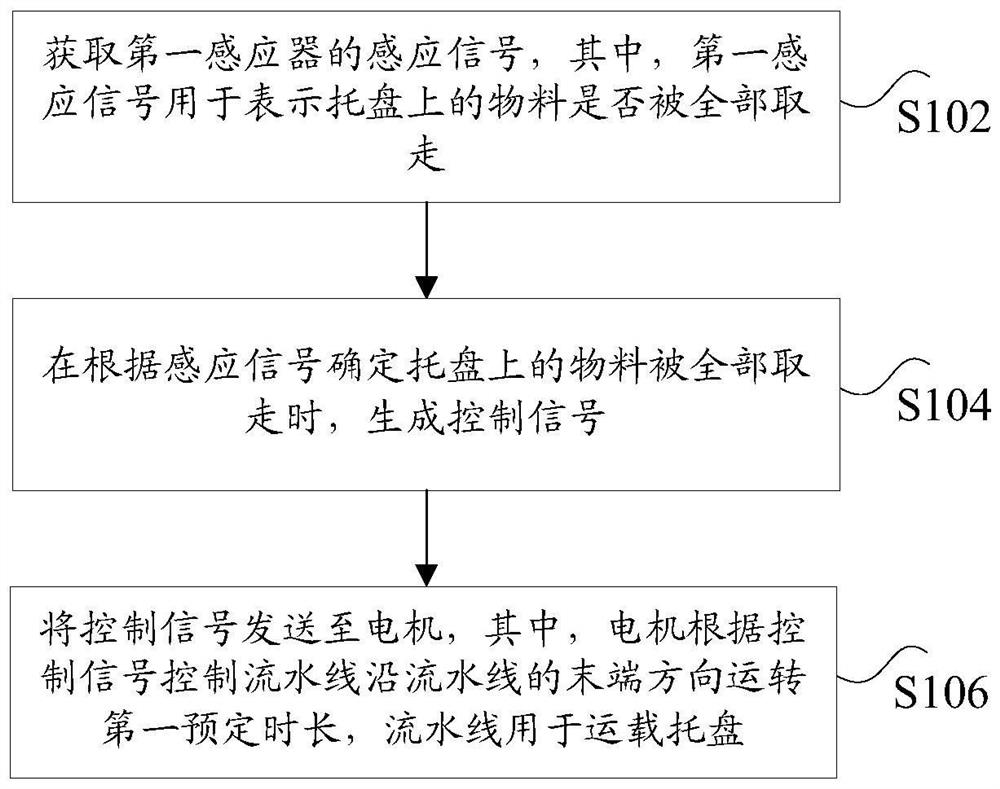

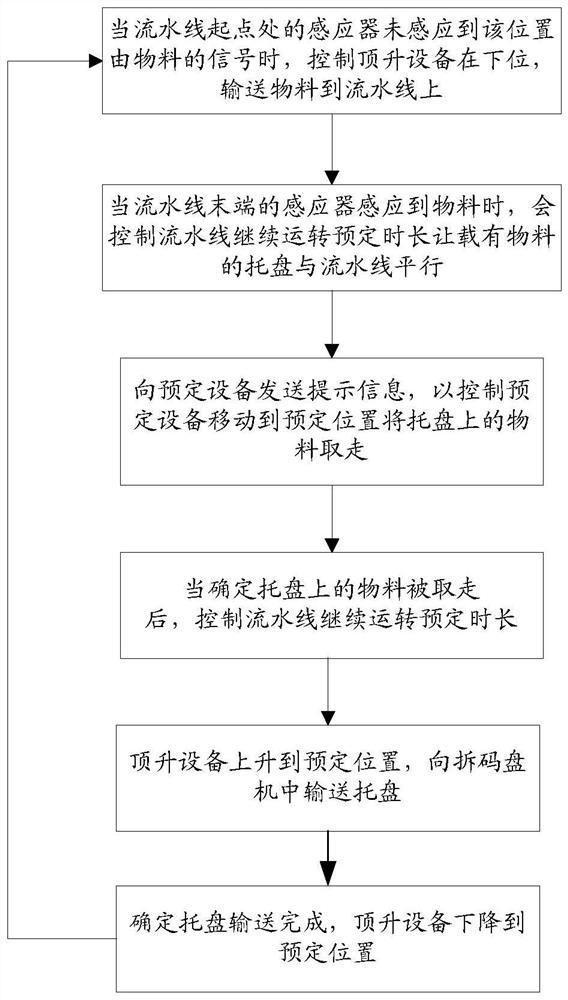

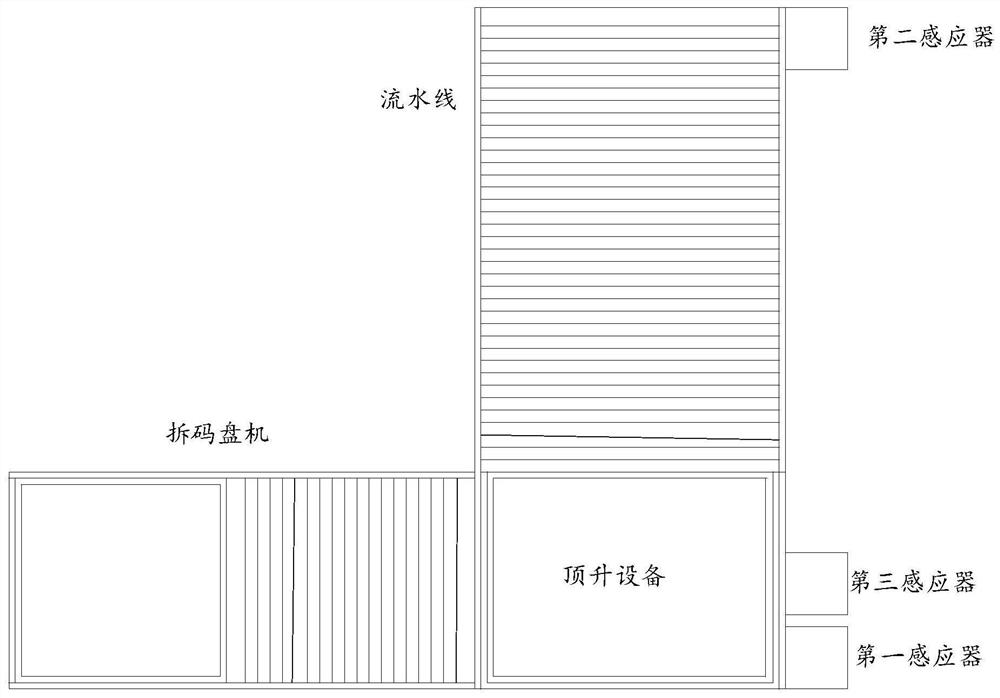

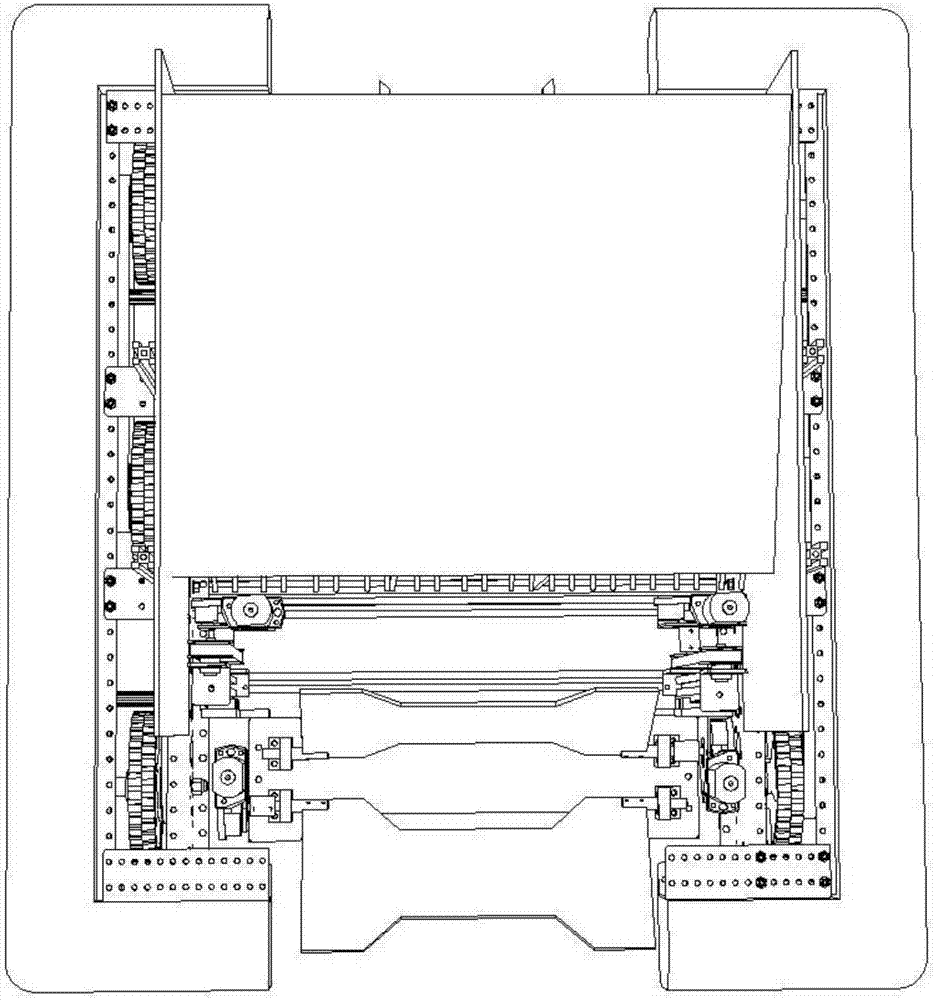

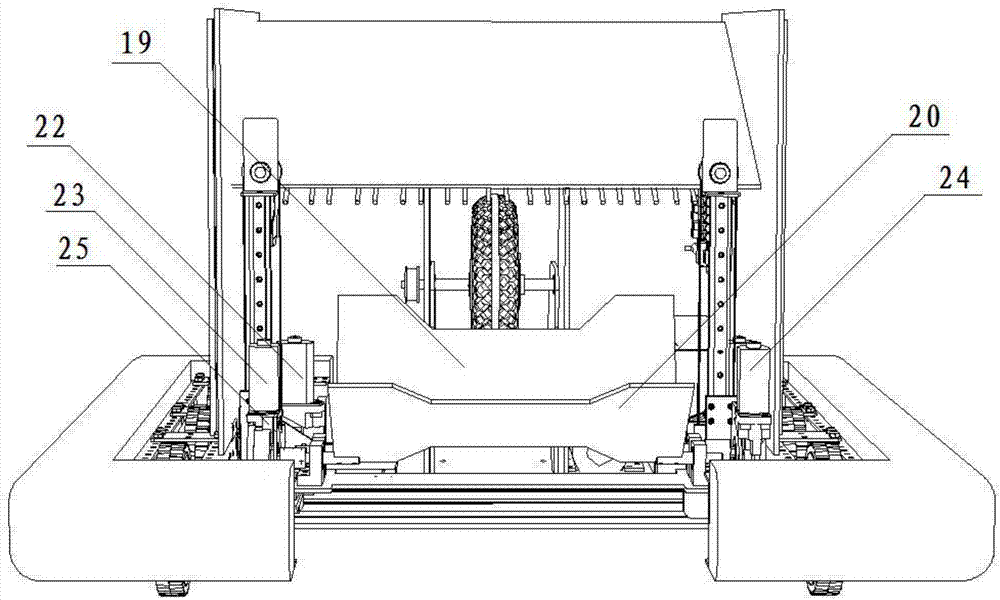

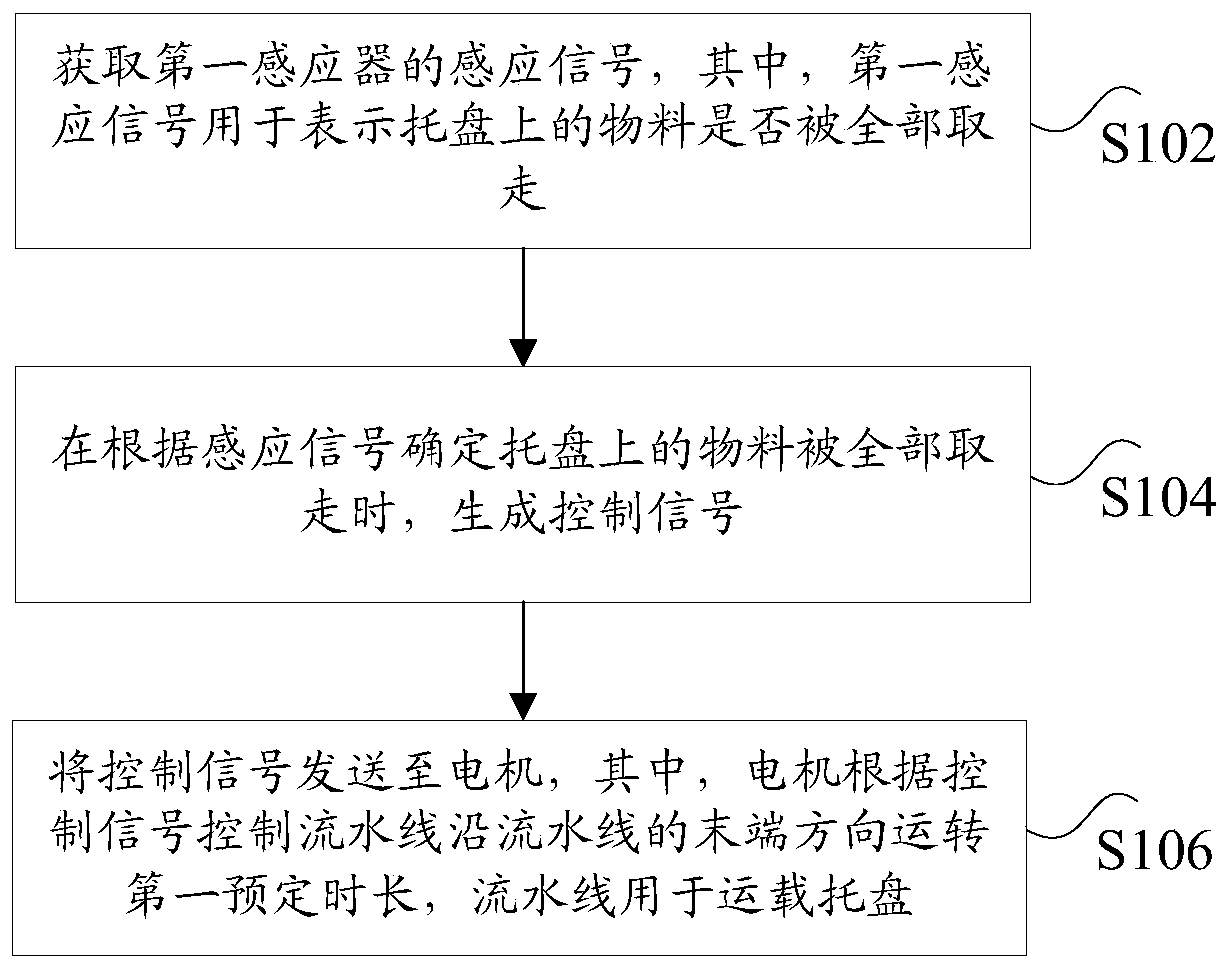

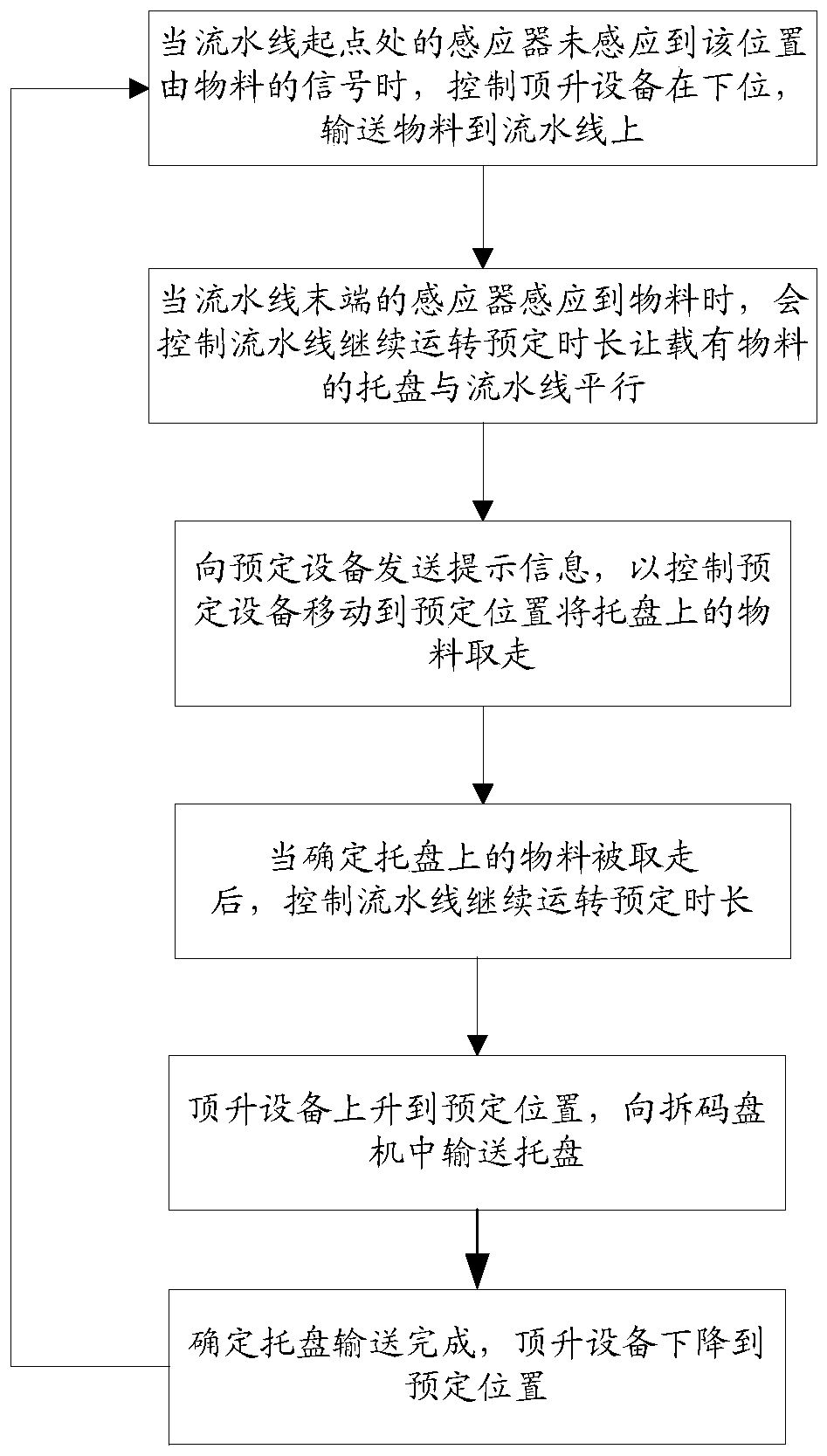

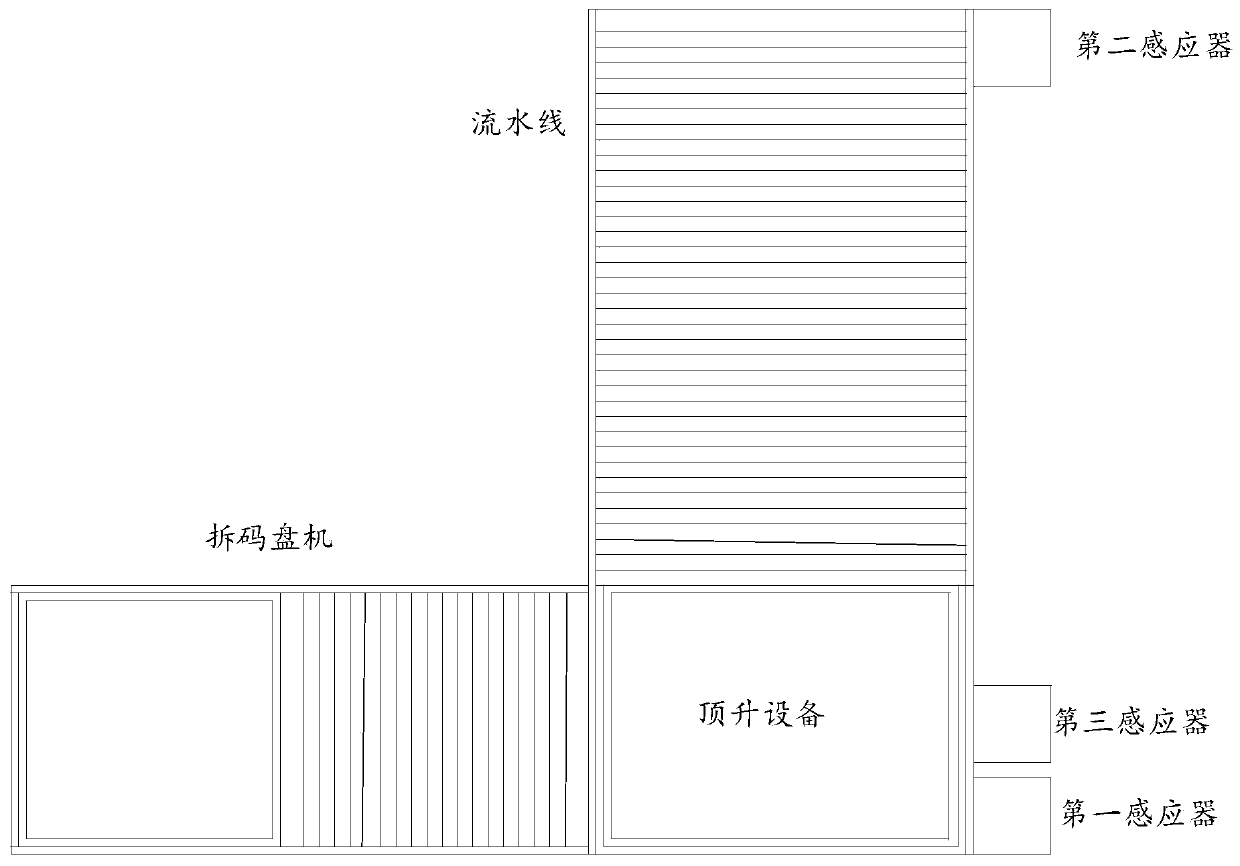

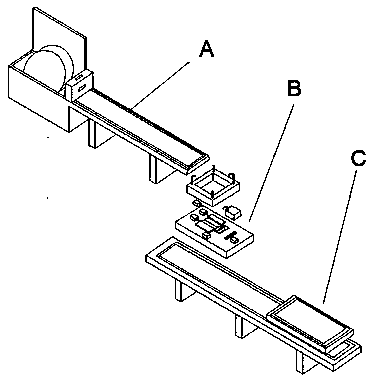

Control method and device for automatically correcting pallet displacement

ActiveCN110194344BImprove operational efficiencyTroubleshoot technical issues that are not functioning properlyStorage devicesControl signalControl engineering

The invention discloses a control method and device for automatically correcting pallet displacement. Wherein, the method includes: acquiring the induction signal of the first sensor, wherein the first induction signal is used to indicate whether all the materials on the tray have been taken away; when it is determined according to the induction signal that all the materials on the tray have been removed, generating Control signal; sending the control signal to the motor, wherein the motor controls the assembly line to run along the end direction of the assembly line for a first predetermined time according to the control signal, and the assembly line is used to carry the pallet. The invention solves the technical problem in the related art that after the materials on the pallets are taken away, the pallets cannot normally enter the unpacking disk machine, which affects the normal operation of the entire warehouse system.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

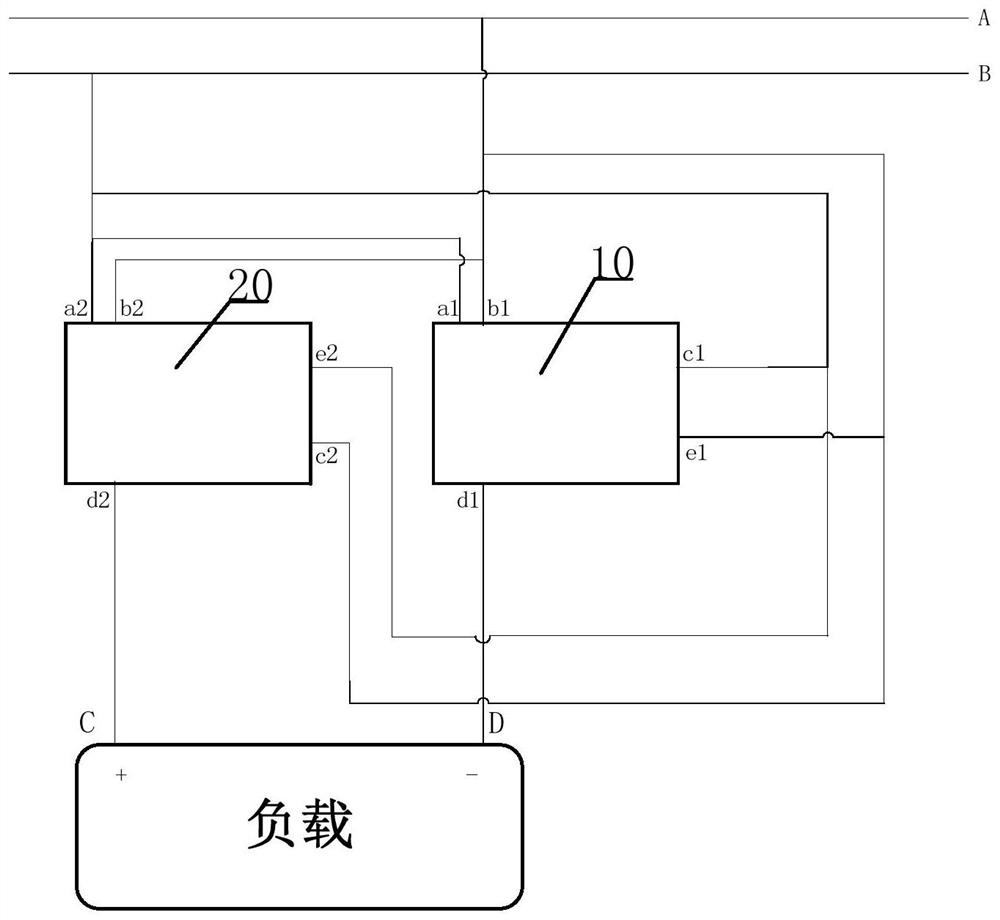

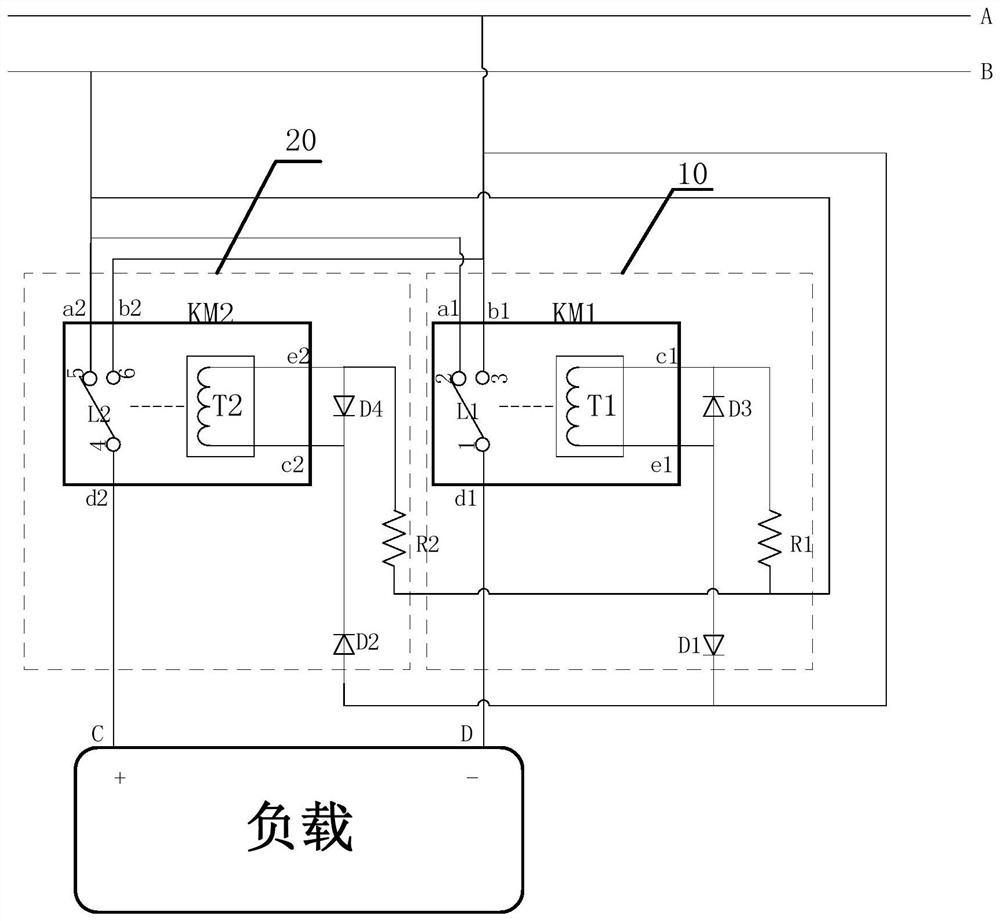

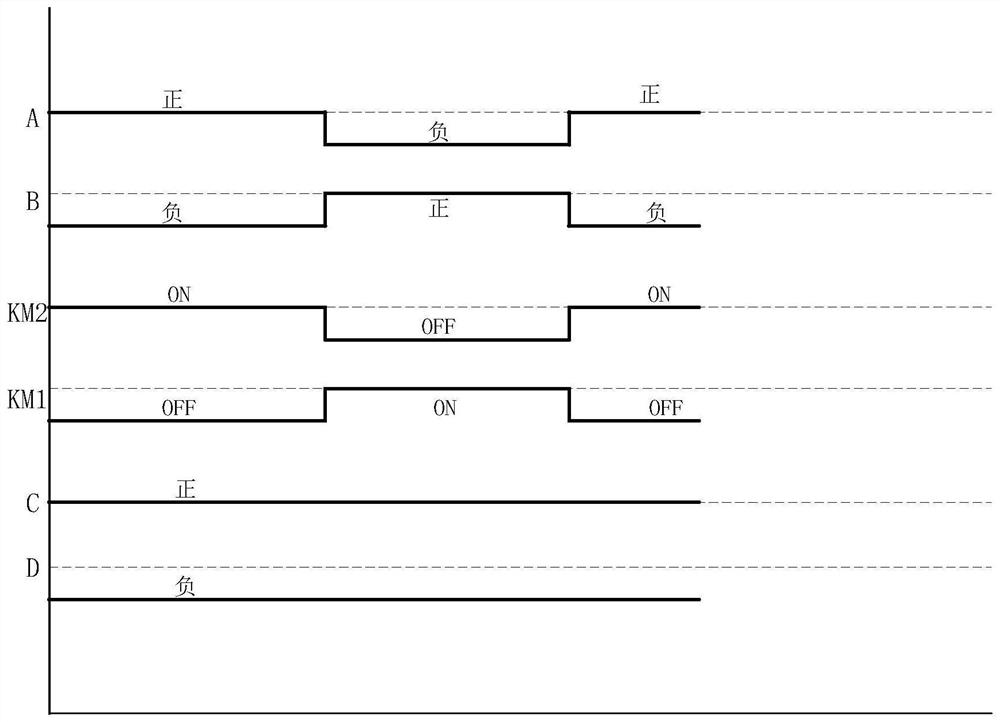

Reverse connection self-correcting circuit and electric equipment

PendingCN112187235AEasy to useImplement auto-correctionElectronic switchingRelaysControl engineeringElectrical polarity

The invention discloses a reverse connection self-correcting circuit and electric equipment. The circuit comprises a first switch module of which the first input end and the third input end are connected with a second line of a power supply, the second input end and the second output end are connected with a first line of the power supply, and the first output end is connected with a negative terminal of a load, and which is used for controlling the first input end or the second input end to bealternatively conducted with the first output end according to polarities of the first line and the second line; a second switch module of which the first input end and the second output end are connected with the second line of the power supply, the second input end and the third input end are connected with the first line of the power supply, and the first output end is connected with the positive terminal of the load, and which is used for controlling the first input end or the second input end to be alternatively conducted with the first output end according to the polarities of the first line and the second line. According to the circuit, automatic correction after reverse connection canbe realized, and normal use of the load can be ensured all the time.

Owner:GREE ELECTRIC APPLIANCES INC

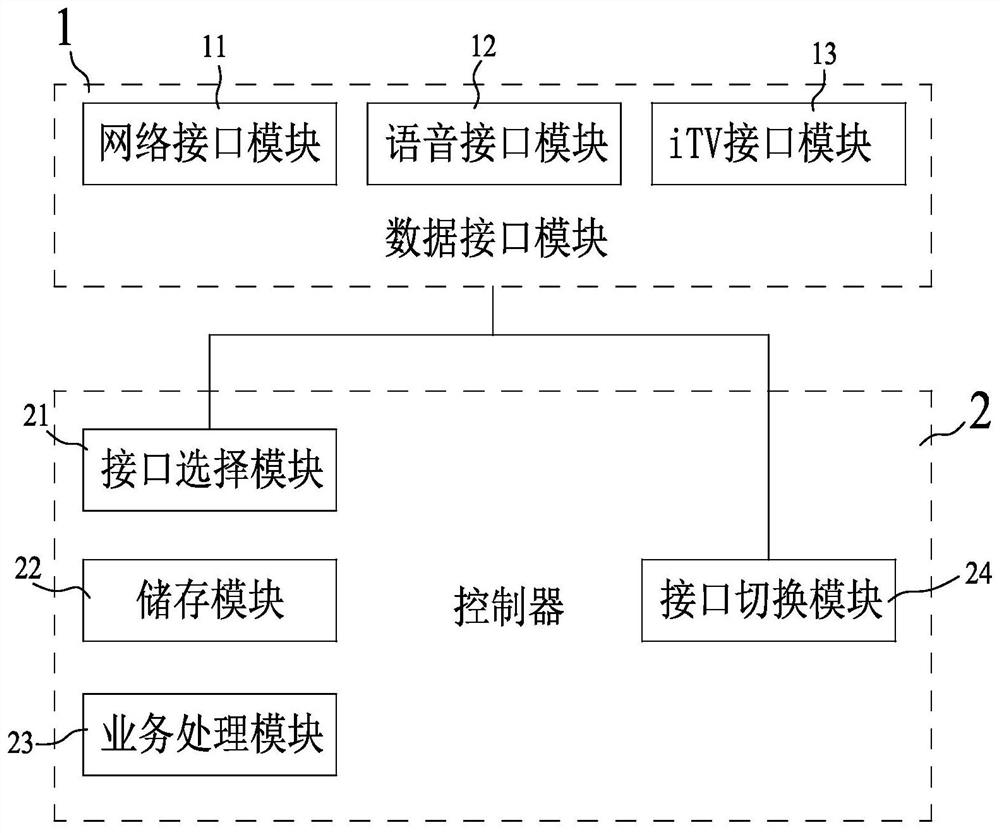

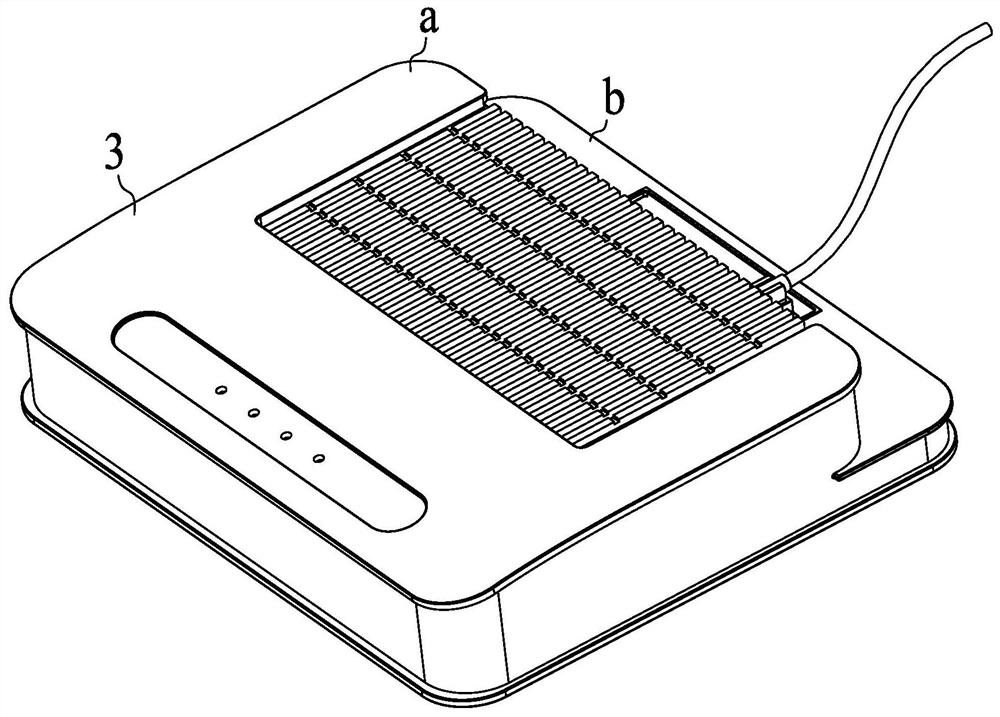

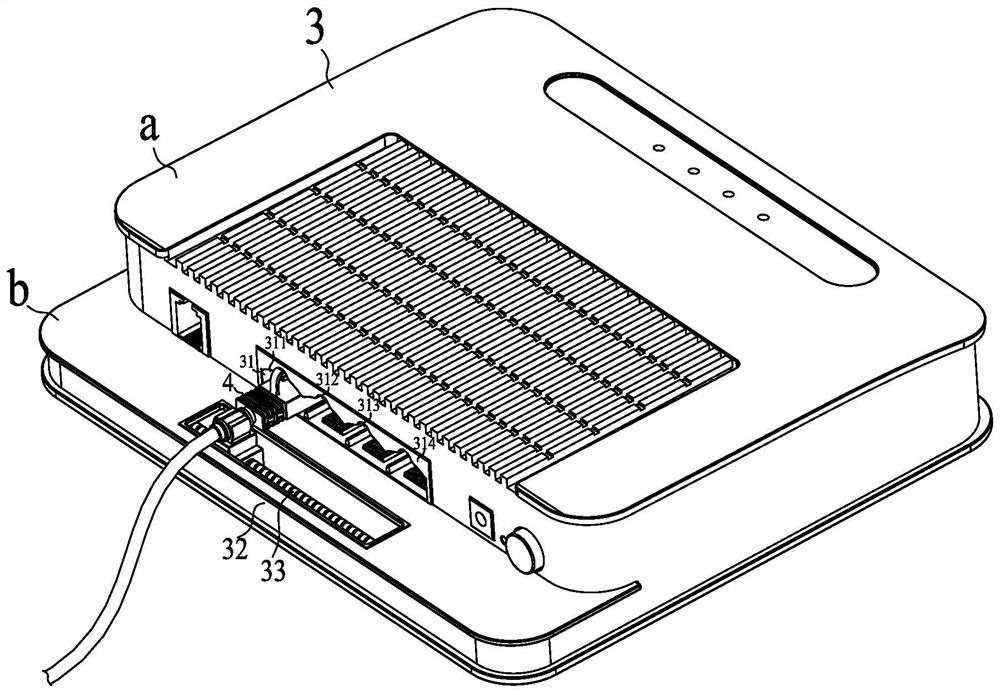

A communication networking device based on security key

ActiveCN110391915BImplement auto-correctionGuaranteed stabilityData switching detailsSelection arrangementsNetwork communicationData interface

Owner:SHENZHEN LOTUT INNOVATION DESIGN CO LTD

All-terrain part conveying robot

ActiveCN107877484ARealize all-terrain handlingImplement auto-correctionVehicular energy storageManipulatorGear wheelControl engineering

The invention discloses an all-terrain part conveying robot. The all-terrain part conveying robot comprises a main body support and a plurality of rollers, wherein the rollers are fixed on the edge ofthe inner side of the main body support; a power distribution panel, a router and a main controller are arranged on the main body support; a rope climbing mechanism is fixedly arranged on the front part of the main body support; an emission mechanism is fixedly arranged on the middle part of the main body support; a picking-up mechanism is fixedly arranged on the rear part of the main body support; the output end of the main controller is separately connected with the input end of the rope-climbing mechanism, the input end of the emission mechanism and the input end of the picking-up mechanism; the power distribution panel is separately electrically connected with the router and the main controller; and the input-output ends of the router are connected with the input-output ends of the main controller. According to the all-terrain part conveying robot, the emission mechanism, the picking-up mechanism and the rope-climbing mechanism are set through the main controller, so that all-terrain conveying for spherical parts and gear parts is realized.

Owner:ZHENJIANG VOCATIONAL TECHN COLLEGE

Control method and device for automatic correction of tray displacement

ActiveCN110194344AImprove operational efficiencyTroubleshoot technical issues that are not functioning properlyStorage devicesControl signalElectric machinery

The invention discloses a control method and device for automatic correction of tray displacement. The method comprises the following steps of acquiring an induction signal of a first sensor, whereinthe first induction signal is used for indicating whether the materials on the tray are completely taken away; when the materials on the tray are determined to be completely taken away according to the induction signals, a control signal is generated; the control signal is sent to the motor, the motor is used for controlling the assembly line to run along the tail end direction of the assembly line for a first preset time length according to the control signal, and the assembly line is used for carrying a tray. The control method and the device solves the technical problem that in the relatedart, after the materials on the tray are taken away, the tray cannot normally enter the tray disassembling tray to influence the normal operation of the whole warehouse system.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

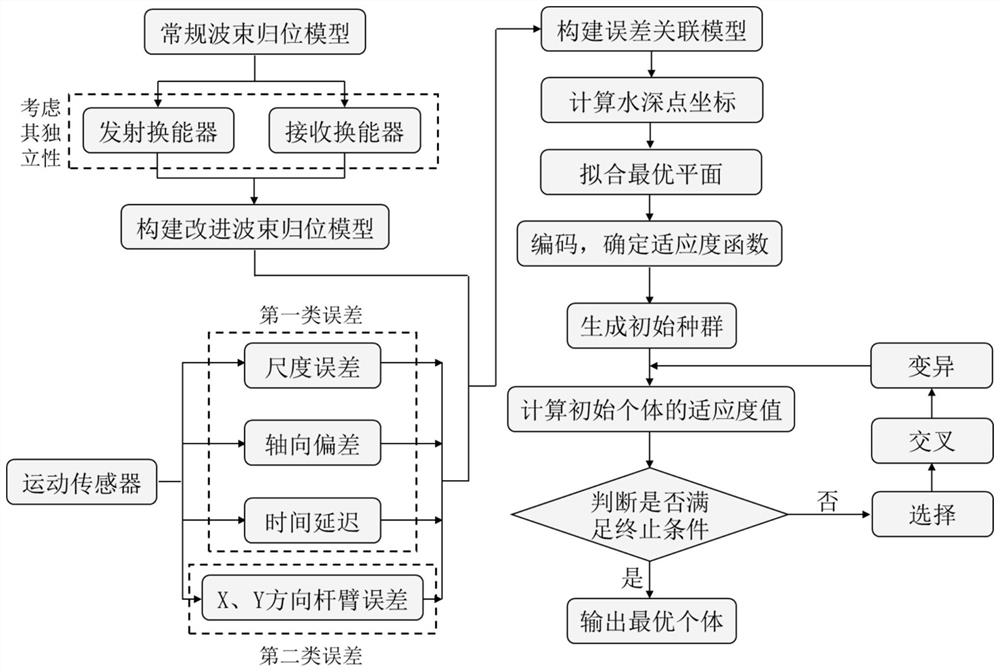

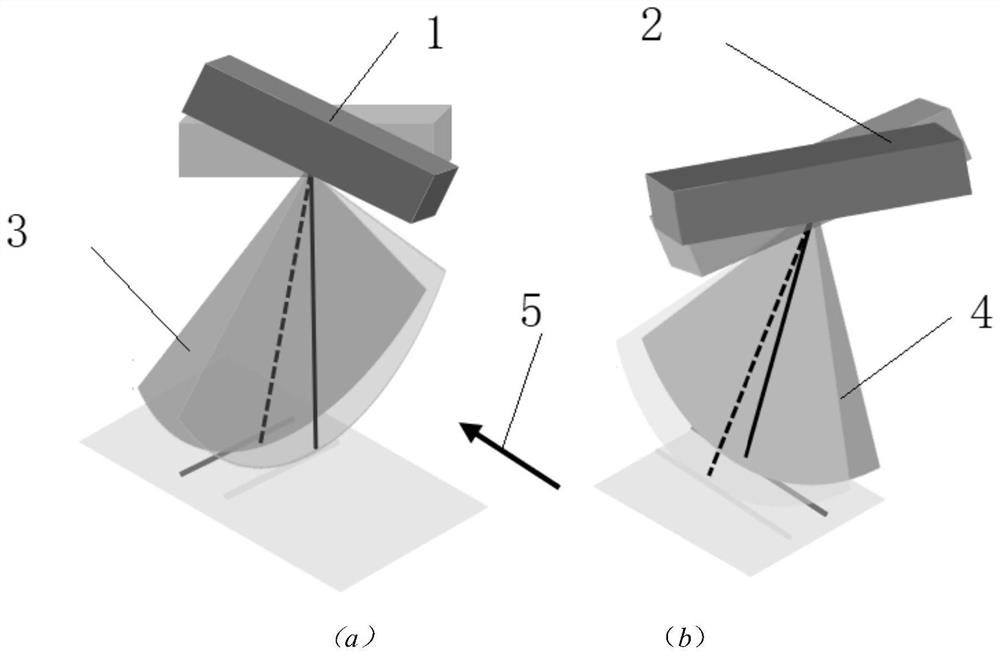

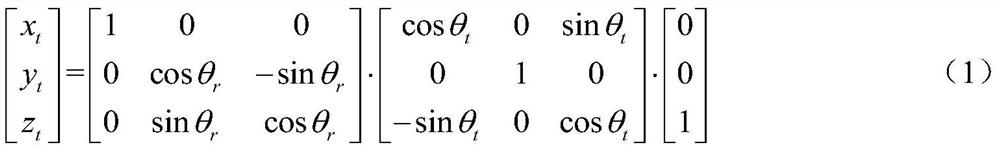

GA algorithm-based shallow water multi-beam wrinkle error automatic correction method

ActiveCN113688562AImprove imputation accuracyImplement auto-correctionWater resource assessmentDesign optimisation/simulationAlgorithmTransducer

The invention discloses a GA algorithm-based shallow water multi-beam wrinkle error automatic correction method, and belongs to the technical field of multi-beam sounding post-processing. The method comprises the following steps: firstly, on the basis of keeping the linear characteristic of a conventional beam homing model, improving and perfecting the independence of the model, and considering the independence of a transmitting transducer and a receiving transducer, so that the accuracy of the sounding point position and the water depth calculation is improved; then, from the perspective of multi-beam sounding error propagation, parameterization of time delay, introducing the scale error, axial deviation and lever arm error into the improved model, and constructing an error correlation model; and finally, dynamically searching an optimal estimated value of a corresponding error parameter by using a GA algorithm by taking a seabed flat region fitting optimal plane as a constraint so as to realize automatic correction of the wrinkle error. According to the method, fine and automatic processing of multi-beam sounding dynamic errors is realized, and the problems that coupling among the errors is not taken into consideration during wrinkle error correction, and non-automation is realized are effectively solved.

Owner:SHANDONG UNIV OF SCI & TECH

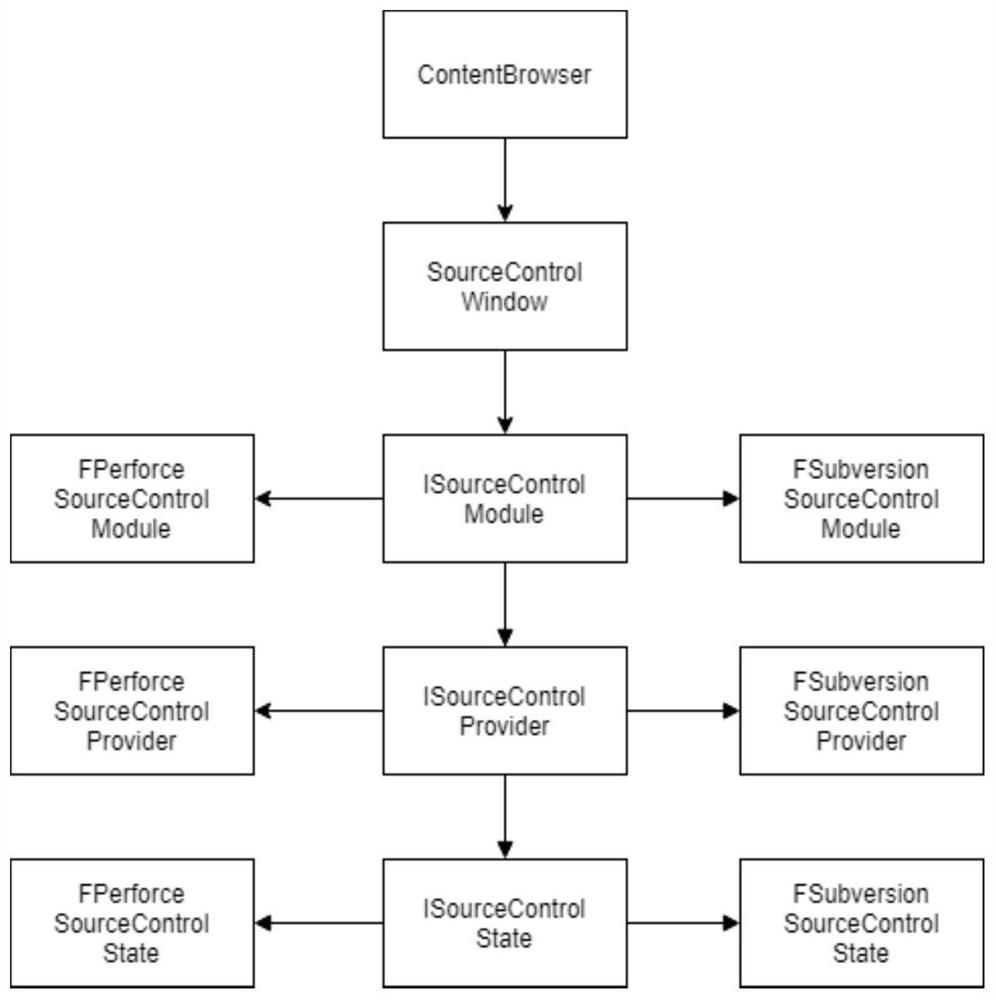

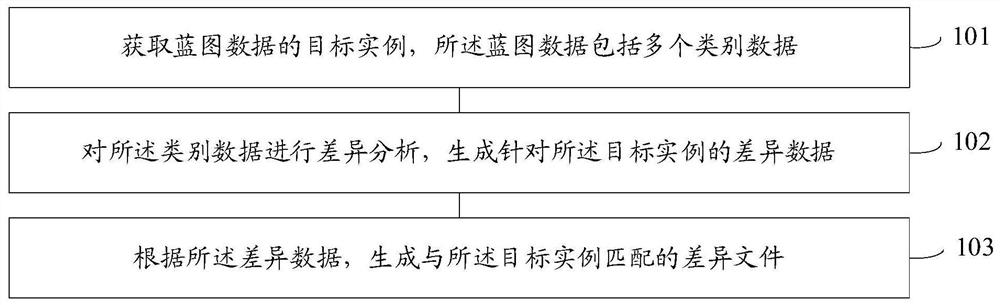

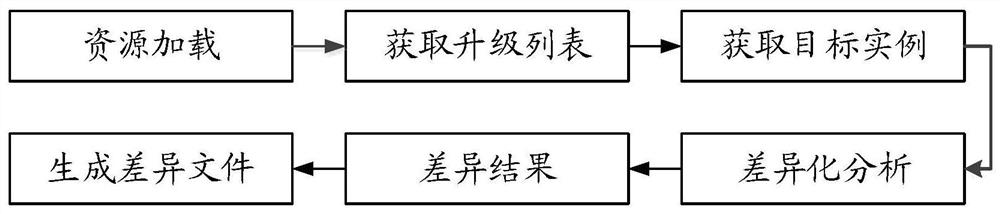

Differential processing method and device for blueprint data

PendingCN112597057AReduce workloadImprove scalabilityVersion controlSoftware testing/debuggingThird partyEngineering

The embodiment of the invention provides a differential processing method and device for blueprint data. The method comprises the steps: obtaining a target instance of the blueprint data which can comprise a plurality of types of data, carrying out the differential analysis of all types of data, generating difference data for the target instance, and according to the difference data, generating adifference file matched with the target instance. Data monitoring analysis can be conducted on various types of data of the blueprint data according to the target instance in the background to obtainthe difference data, the workload of a tester is reduced, the monitoring precision is improved, the risk of program errors is reduced, and according to the difference data, the difference file corresponding to the target instance is generated, so that the difference data can be read by a third-party tool, the expansibility of automatic monitoring is improved, a tester can perform detection throughthe monitoring tool in the background monitoring process, automatic correction and early warning are realized, and the quality of engineering development is ensured.

Owner:NETEASE (HANGZHOU) NETWORK CO LTD

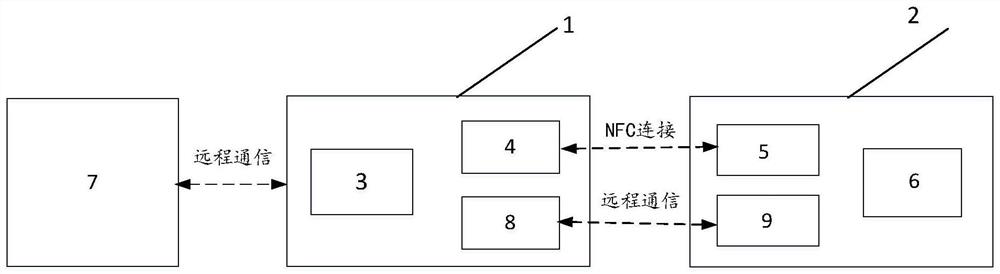

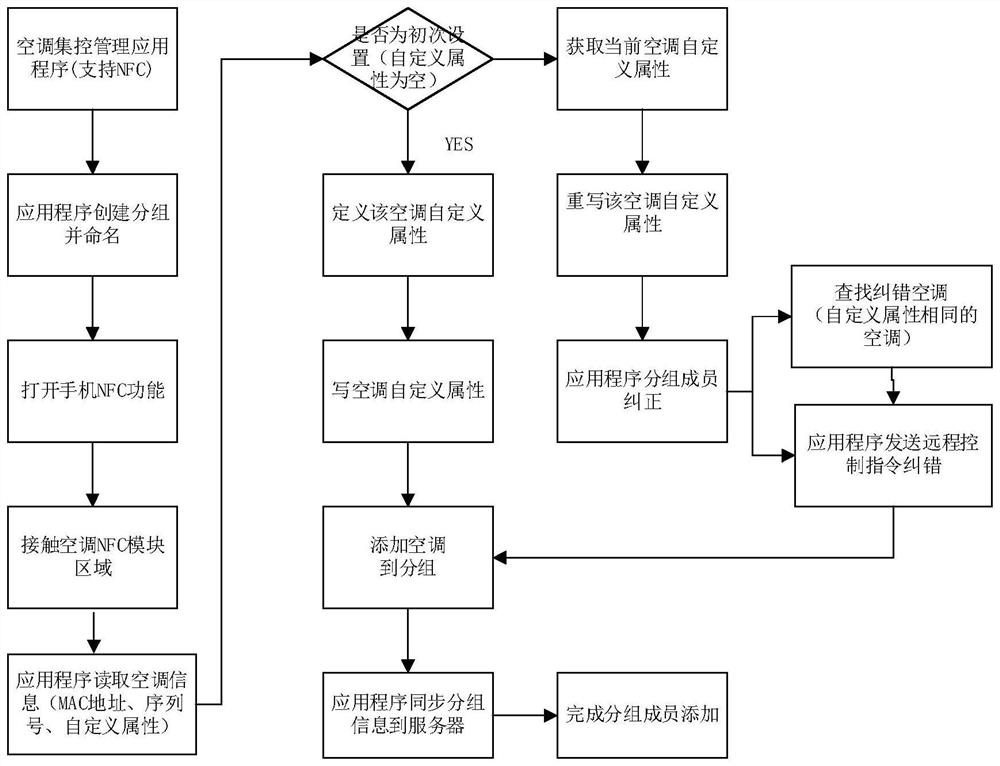

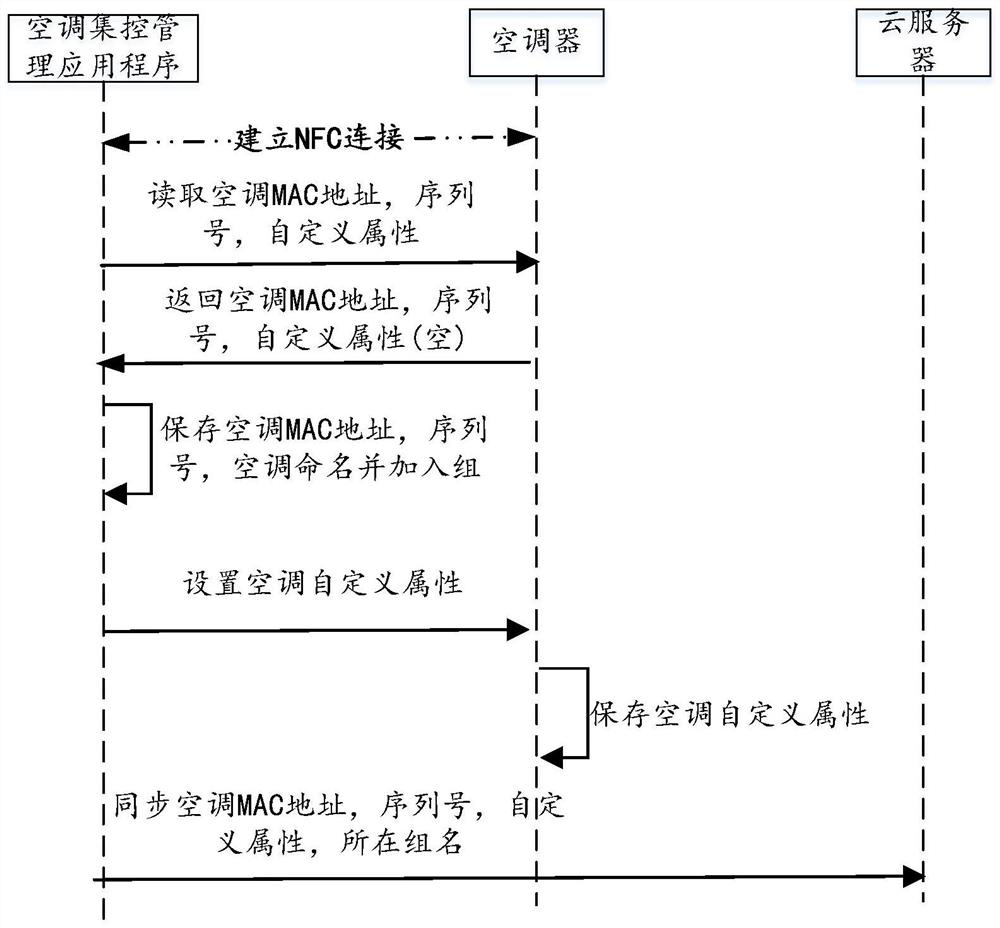

Air conditioner group control method, module, air conditioner and readable storage medium

ActiveCN111271811BImplement addImplement auto-correctionMechanical apparatusSpace heating and ventilation safety systemsControl engineeringProcess engineering

The present invention provides an air conditioner group control method, a module, an air conditioner, and a readable storage medium, and a group control method for air conditioner centralized control management. The control method includes: the air conditioner centralized control management application program reads the The information of the air conditioner NFC module is written into the air conditioner NFC module of the air conditioner after the definition of the custom attribute of the air conditioner, the air conditioner is added to the group corresponding to the attribute according to the custom attribute, and the group information is sent to the server . The invention can realize adding, deleting, modifying and automatically correcting the grouping members of the air conditioners. The invention has the advantage of realizing rapid grouping, grouping adjustment and automatic correction of air conditioners.

Owner:NINGBO AUX ELECTRIC +1

An automatic cutting machine cutting knife deformation detection device

ActiveCN103776360BImplement auto-correctionProgramme controlComputer controlDigital transformationEngineering

The invention provides an automatic cutting bed cutter deformation detection device. According to the device, the cutter deformation caused by cutting cloth in the rotation process of the cutter is detected in real time through a displacement sensor, and the detected analog voltage signal is subjected to digital transformation. Under the control of a program in a micro controller, firstly the cutter deformation is analyzed and judged, then a servo motor is controlled and the cutter is driven to carry out rotation compensation to the opposite direction of deformation, and the automatic correction of the cutter cutting direction is realized. The fact that the cutting error caused by the cutter deformation is always controlled in an allowable range is ensured, and the cutting quality and precision are raised.

Owner:MIANYANG WEIBO ELECTRONICS

Weight Analysis Method of Distribution Network Equipment Status Index Based on Conjoint Analysis Method

ActiveCN104182583BImplement auto-correctionReduce in quantityData processing applicationsSpecial data processing applicationsJoint analysisDevice Grid

The present invention provides a weight analysis method for distribution network equipment status indicators based on a joint analysis method, comprising: step 1: using an orthogonal test to determine the investigation card of the distribution network equipment status indicators; step 2: scoring the investigation card; step 3: Check the consistency of the scoring data; step 4: use the least squares method to fit the scoring data with consistency and verify the validity of the scoring data to obtain the weight of the distribution network equipment status index. Compared with the prior art, the distribution network equipment status index weight analysis method based on the joint analysis method provided by the present invention can reduce the number of investigation cards without affecting the implementation effect of the joint analysis method, and the data of the investigation cards Perform consistency checks and adjustments.

Owner:STATE GRID CORP OF CHINA +2

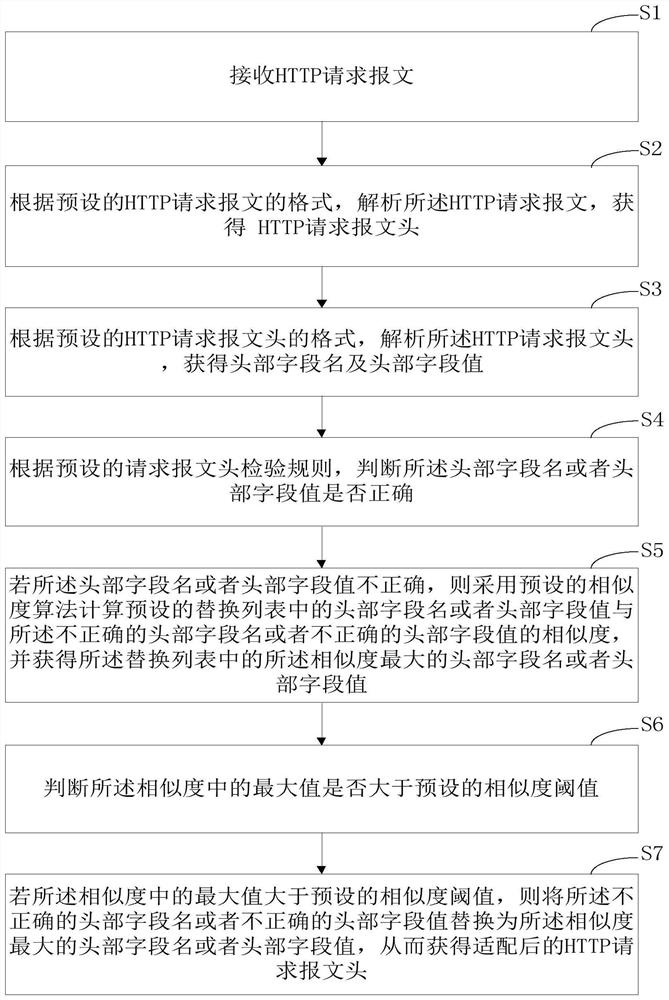

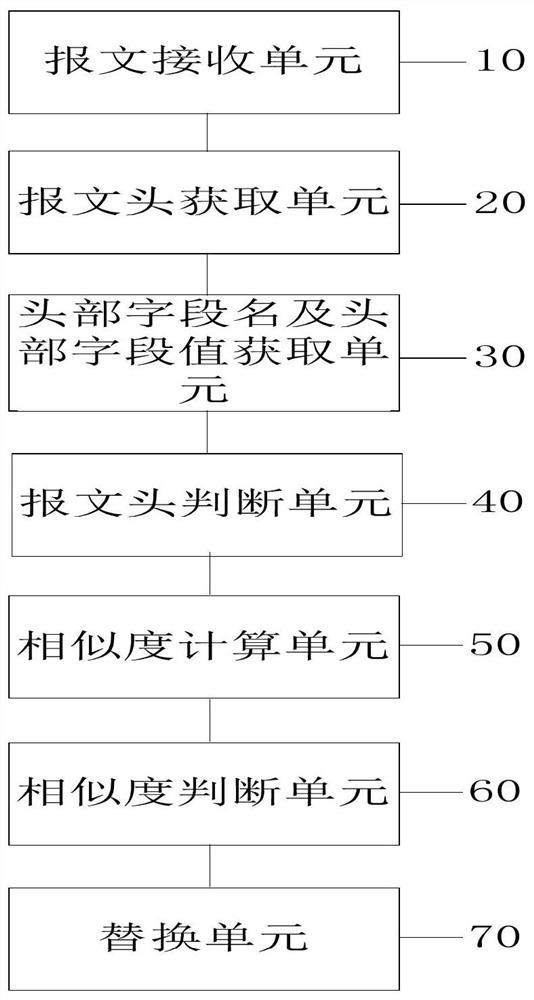

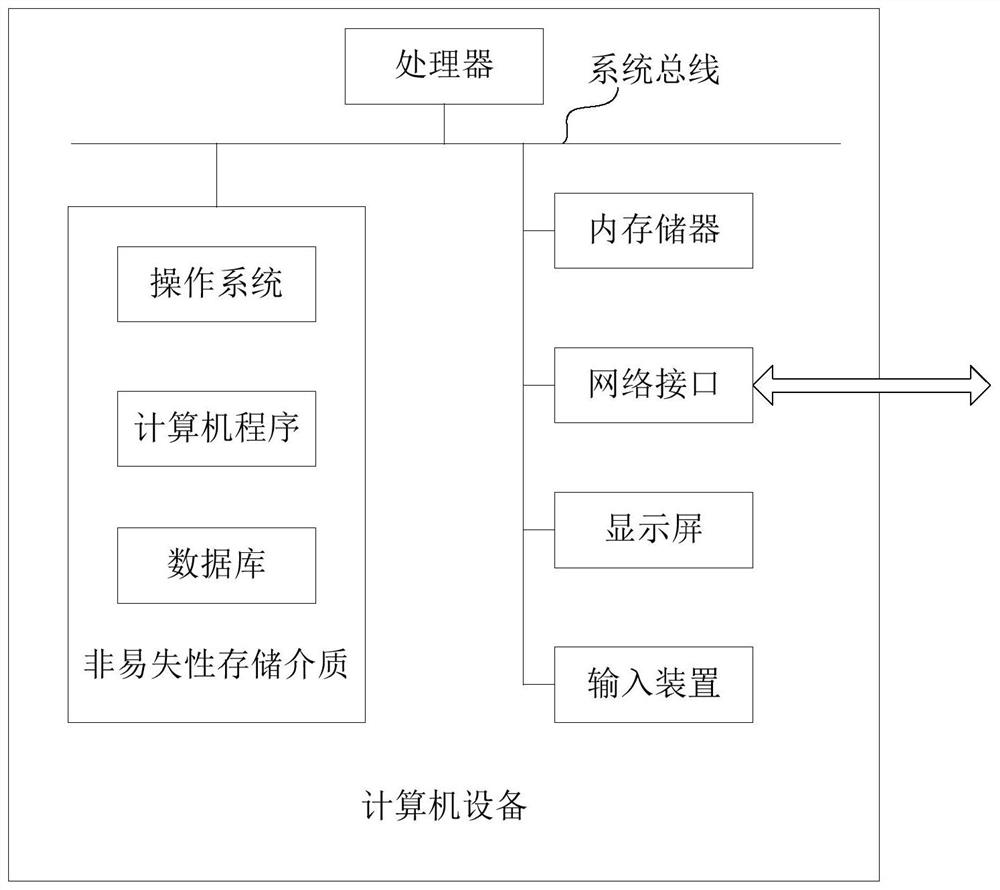

Adaptation method, device and computer equipment for http request message header

The present application discloses an adaptation method, device, computer equipment and storage medium of an HTTP request message header. The method includes: receiving an HTTP request message; parsing the HTTP request message to obtain the HTTP request message header; parsing the HTTP request message header; Request the message header, obtain the header field name and header field value; judge whether the header field name or header field value is correct; if the header field name or header field value is incorrect, calculate the preset replacement list The similarity between the header field name or header field value and the incorrect header field name or incorrect header field value; if the maximum value in the similarity is greater than the preset similarity threshold, the incorrect header The field name or incorrect header field value is replaced with the header field name or header field value with the highest similarity, so as to obtain the adapted HTTP request header. In this way, the incorrectly adapted request packet header is automatically corrected, reducing unnecessary network overhead.

Owner:PING AN TECH (SHENZHEN) CO LTD

An Adaptive Answer Sheet Sequence Correction Method

ActiveCN112001416BImplement auto-correctionNeural architecturesNeural learning methodsComputer graphics (images)Radiology

One or more embodiments of this specification provide a method for correcting an adaptive answer sheet sequence, including: acquiring the A-side scan image, the B-side scan image, and the original image sequence of the student's answer sheet; Segment the scanned image respectively to obtain the A-side image block and the B-side image block containing the student's handwriting; input the A-side image block and the B-side image block into the pre-trained handwriting matching model to obtain the original image sequence The matching result of the adjacent A-side scan image and B-side scan image; the A-side scan image and B-side scan image that are not successfully matched in the matching results are input into the pre-trained handwriting search model, for each A-side The scanned image searches for the matching B-side scanned image, so as to realize the automatic correction of the answer sheet sequence.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Simulation system communication method and simulation system

ActiveCN104038309BAvoid false positivesImprove anti-interference abilityError prevention/detection by using return channelCommunications systemError processing

The present invention provides a simulation system communication method and a simulation system, wherein the method includes: a master device sends a request message to a slave device; the master device receives one of the request-response messages returned by the slave device, and judges the Whether the reception of one of the request-response messages has timed out, the request-response messages include the processing result of the first message returned by the slave device when it determines that the request message is the first message, and the slave device The response message of the request message returned when it is determined that the request message is the second message; the master device resends the request message or performs timeout error processing when receiving the request message overtime. The simulation system communication method and the simulation system provided by the invention are used to solve the problems of communication failure or simulation data error caused by the interference of the simulator, improve the anti-interference and stability of the simulator, and realize automatic correction.

Owner:SHANGHAI EASTSOFT MICROELECTRONICS

An intelligent heat insulation board combined processing device with offset compensation mechanism

ActiveCN114572673BImplement auto-correctionImprove adhesionConveyorsLamination ancillary operationsMechanical engineeringIntelligent control system

Owner:江苏逸欣节能科技有限公司

Equipment for fully-automatically making spring rolls and method for fully-automatically making spring rolls

PendingCN109548815ANo human intervention requiredSo as not to damageDough processingFailure rateEngineering

The invention discloses equipment for fully-automatically making spring rolls and a method for fully-automatically making the spring rolls. Spring roll wrappers (cut as required) are delivered onto abearing table through a spring roll wrapper delivering unit, and jet units are used for blowing off the spring roll wrappers placed on the bearing table from wrapper dropping holes; the spring roll wrappers always drop down from one wrapper dropping hole, so that the situation that the spring roll wrappers can accurately fall on a specified position can be guaranteed; besides, the spring roll wrappers do not need to be turned over through other mechanical structures, but are blown off through the jet units, so that the efficiency can be greatly improved, the failure rate is reduced, and the situation that the spring roll wrappers cannot be destroyed can be better guaranteed; semi-finished products of the spring rolls are made at a spring roll wrapper placing region, and the spring roll wrappers do not need to be delivered to multiple positions to be made; through a rolling device, the semi-finished products of the spring rolls are rolled to obtain finished products of the spring rolls,so that the wrapping efficiency is greatly improved; and through a pulp solidification machine, pulp solidification is performed on the spring roll wrappers, when the semi-finished products of the spring rolls are made into the finished products of the spring rolls subsequently, through adhesion of starch glue, the spring rolls cannot disperse and can be better shaped, and the quality of the shaped spring rolls can be greatly guaranteed.

Owner:青岛乐佳食品机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com