An online detection and correction system for laser shock processing based on workpiece vibration frequency

A vibration frequency, laser shock technology, applied in the direction of optical testing flaws/defects, can solve problems such as affecting quality, target material damage, reducing crack growth rate, etc., to improve impact speed and efficiency, low cost, and low external environment requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

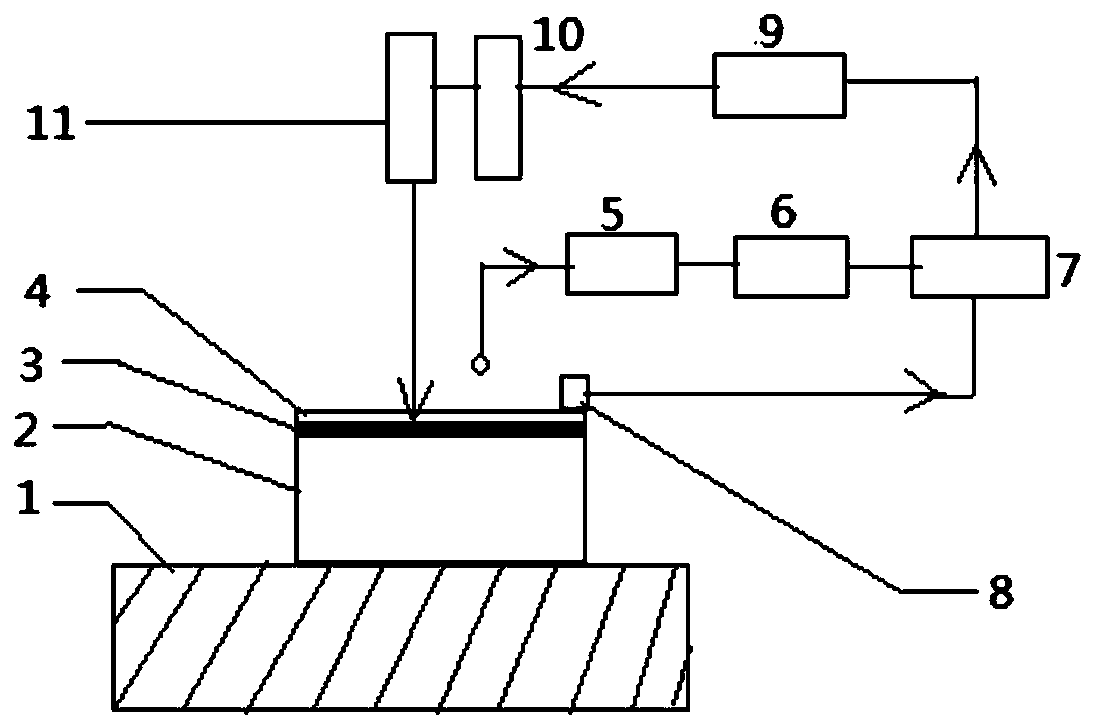

[0012] See figure 1 , An online detection system for laser shock processing based on the vibration frequency of the workpiece, including a delay system, a control and vibration sensing system; the delay system includes a photoelectric trigger 5 and a delay 6, the photoelectric trigger 5 generates a pulse signal and sends it to Delay 6, the pulse signal of the photoelectric trigger 5 is used as the trigger pulse signal of the vibration sensor 7 to control the time period of the vibration sensor 7; the control and vibration sensing system includes the vibration sensor 7, the vibration sensor contact 8, the computer 9, The automatic controller 10, the laser 11, and the vibration sensor 7 collect the vibration signal of the target material 2 through the vibration sensor contact 8, and transmit the digital signal to the computer 9 through A / D conversion, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com