Control method and device for automatic correction of tray displacement

A technology of automatic correction and control methods, which is applied in the direction of storage devices, transportation and packaging, etc., can solve problems such as the failure of the warehouse system to operate normally, and achieve the effect of improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

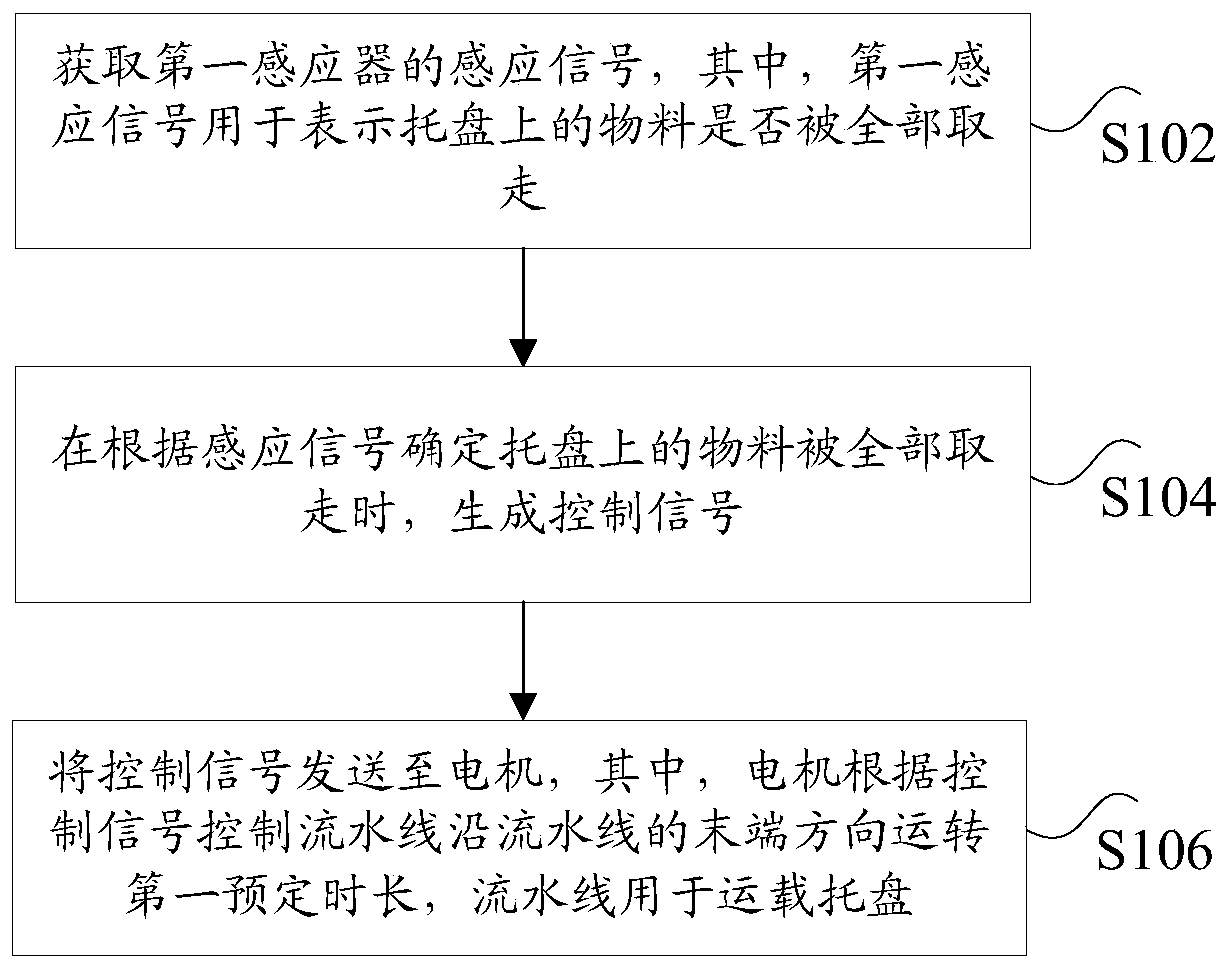

[0029] According to an embodiment of the present invention, a method embodiment of a control method for automatically correcting pallet displacement is provided. It should be noted that the steps shown in the flow chart of the accompanying drawings can be implemented in a computer system such as a set of computer-executable instructions and, although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

[0030] figure 1 is a flowchart of a control method for automatically correcting pallet displacement according to an embodiment of the present invention, such as figure 1 As shown, the control method for automatically correcting the pallet displacement includes the following steps:

[0031] Step S102, acquiring the sensing signal of the first sensor, wherein the first sensing signal is used to indicate whether all the materials on the tray have been taken away.

[003...

Embodiment 2

[0053] According to another aspect of the embodiments of the present invention, an embodiment of an apparatus for performing a control method for automatically correcting pallet displacement is also provided, Figure 4 is a schematic diagram of a control device for automatically correcting pallet displacement according to an embodiment of the present invention, as shown in Figure 4 As shown, the control device for automatically correcting pallet displacement includes: an acquisition unit 41 , a generation unit 43 and a first sending unit 45 . The control device for automatically correcting the pallet displacement will be described in detail below.

[0054] Wherein, the acquisition unit 41 is configured to acquire the sensing signal of the first sensor, wherein the first sensing signal is used to indicate whether all the materials on the tray have been taken away.

[0055] The generating unit 43 is configured to generate a control signal when it is determined according to the...

Embodiment 3

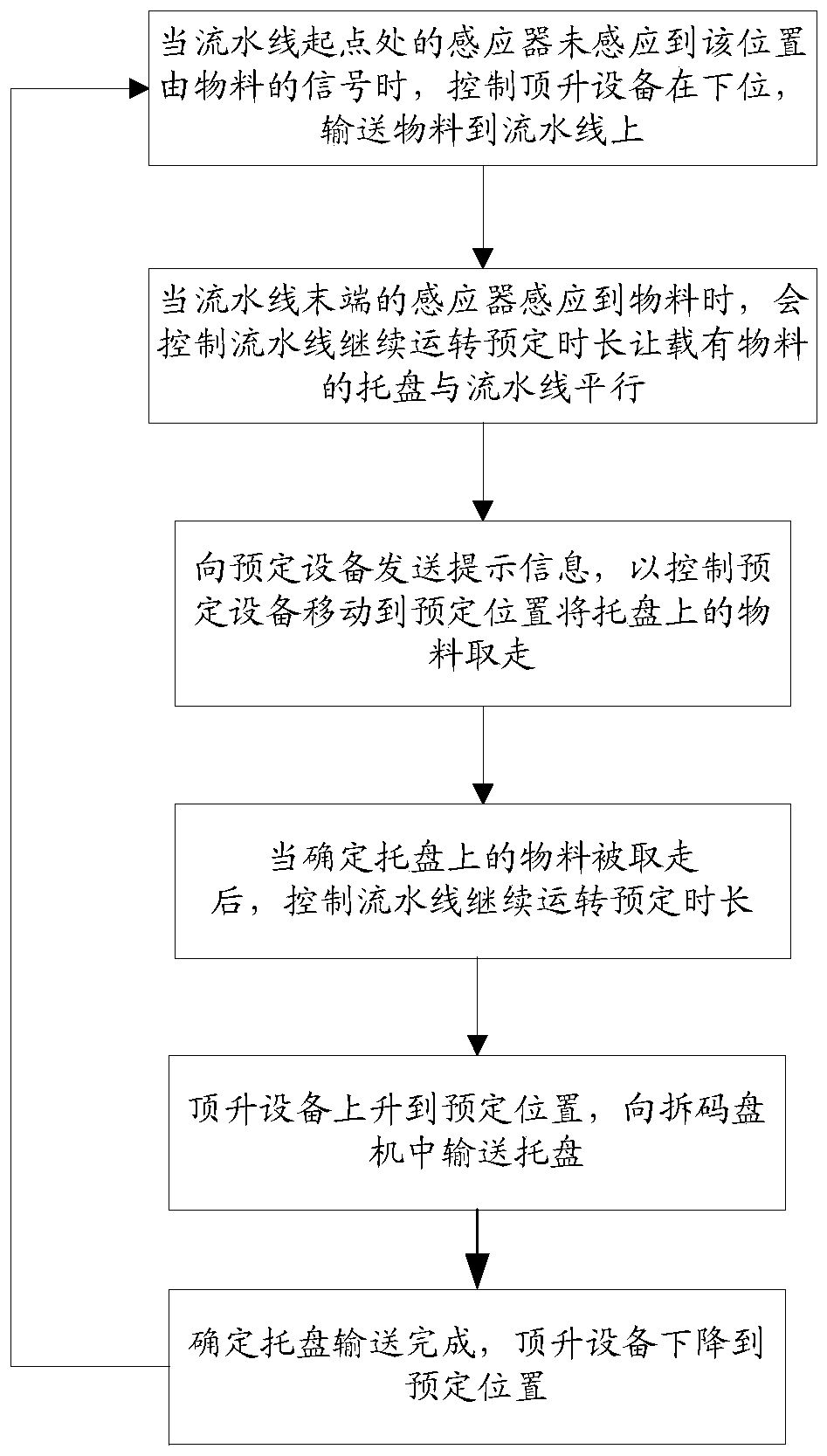

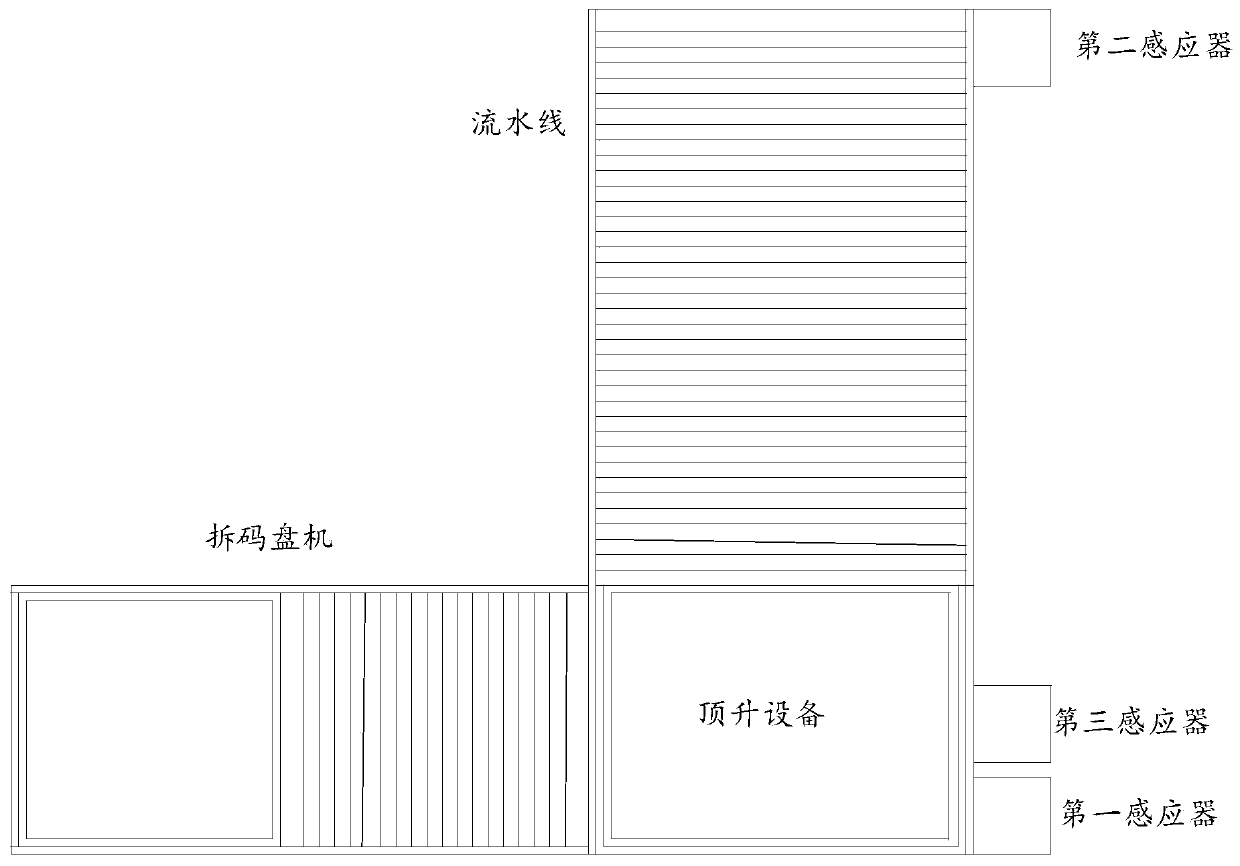

[0065] According to another aspect of the embodiments of the present invention, a control system for automatic correction of pallet displacement is also provided, and the control system for automatic correction of pallet displacement uses any one of the control methods for automatic correction of pallet displacement described above. Wherein, the control system for automatic correction of pallet displacement provided in the embodiment of the present invention adopts PLC control mode, and when the overall assembly line is running, the overall judgment is made through the induction signal of the sensor to realize automatic operation.

[0066] In an application scenario, when materials come out of the three-dimensional warehouse of WCS, they are placed on a pallet. When materials and pallets are transported to the three-dimensional warehouse of WCS, since the box of the assembly line is wider than the pallet, it is necessary to use the sensor to sense the pallet and continue to run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com